The Increasing Complexity of Door Hardware

We demand more of our door hardware these days. As always, we want it to keep the bad guys out and let the good guys in or out, but now we may also want it to keep Alzheimer’s patients in but let their caregivers pass through freely; or open a door automatically for some but not for others; or we may want it to inhibit the progress of smoke and fire while letting those fleeing the flames escape without having to think about it. Some door hardware must resist hurricane winds while other hardware must provide electronic access and be explosion proof.

As a result, choosing door hardware is more of a science than it once was. Those who choose door hardware without prior training may need to consult more than one authority as they make their choices. Those who recommend door hardware must be prepared to research outside their normal sphere of expertise in order to ensure security as well as fire and life safety while providing the functionality that users seek.

Mechanical, Electromechanical and/or Electronic

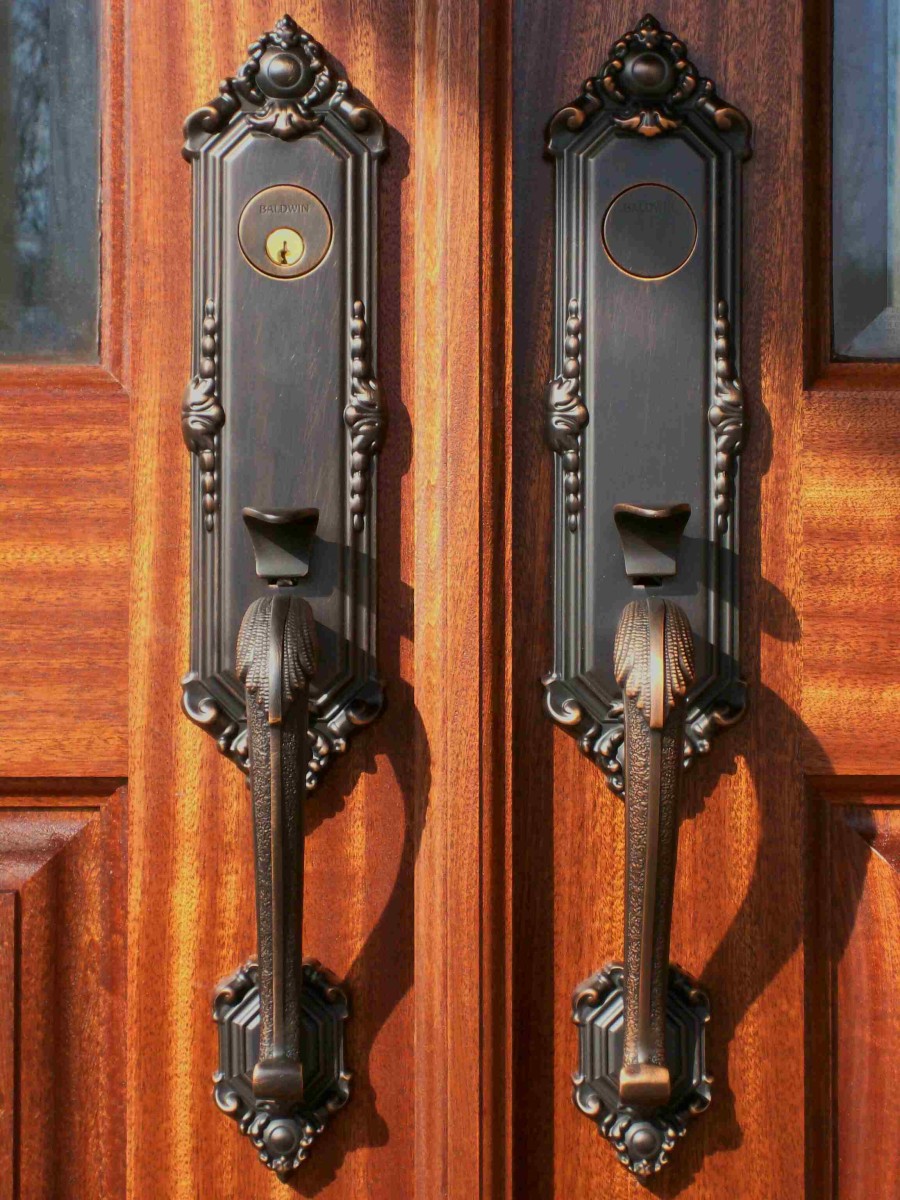

The mechanical function of a locking device – without the further complication of electricity - can be complex all by itself. Combinations of latch, dead latch and bolt, key cylinders outside and/or inside, thumb turns, toggles and occupancy indicators combine in the making of hundreds of functions, each designed for a specific purpose. There are privacy and hotel locks that allow a person to lock themselves inside a room and have an indicator outside that reads, “Do Not Disturb” or “Occupied”, but also allow entrance by special key in an emergency. There are locks that unlock themselves when you shut the door and others that are always locked from one or even both sides. There are locks that are never locked and locks that can be locked three different ways. Some locks lock the outside handle using a key from the inside and some use a key from the outside, and still others use a key from either side.

But mechanical functions are designed to behave the same way every time, given the same input, and they have no memory. Also, mechanical locks can only be given input in person. To make locking systems behave differently in different situations, keep an automatic record of use or to control them remotely, electricity is required.

The first step away from purely mechanical locking is electrification: electric strikes, electrified cylindrical or mortise locks and electric latch retraction or electric trim for exit devices. Electrification allows the user to control the device remotely – for example, a receptionist at a desk can press a button fifty feet away and admit a visitor.

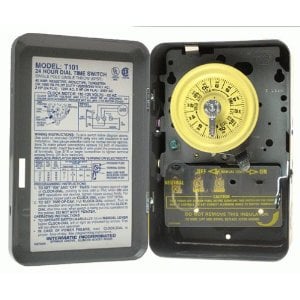

The next step away from purely mechanical locking is commonly called “time zones”: that is, controlling the behavior of a lock electrically though different time periods during the day, week, month or year. This can be done electromechanically with a time switch such as the Intermatic T101, or it can be done electronically using a timer like the Altronix P724A. Typically the Intermatic is used to turn something on at a certain time and off at a certain time, once each day. The Altronix PT724A, however, can lock the door at 9am on Monday, 8am on Tuesday and Wednesday, 9am on Thursday and Friday, 10am on Saturday, and not at all on Sunday, New Years Day, Memorial Day, July Fourth, Labor Day, Thanksgiving or Christmas, and it can automatically adjust itself for daylight saving time.

Levels of Automation

Sometimes the user's needs require different levels of automation.

The ambulance entrance to a hospital emergency room, for example, is usually equipped with power operators to open the door. If security is an issue, these doors may be controlled remotely by a security guard at a station with a hardwired switch, or by the ambulance drivers themselves, using a wireless remote much like those used to open garage doors. At the same time, these same power operators may need to have a "push and go" feature in case of emergency, so that injured, sick or disabled people in the emergency room can get out. In addition, the same entrance may be used by employees or visitors who do not need a power operator to open the door for them. Employees would use an access control system to unlock an electric locking device and would simply pull the door open.

For hardware, besides hinges, I might suggest something like:

- Microprocessor controlled electric/hydraulic automatic double door opener with radio receiver, remote hand-held transmitter-actuators, presence sensors and hardwired actuators

- A delayed egress concealed vertical rod exit only push bar exit device

- A delayed egress mortise exit device with electric mortise body, open back strike and lever exterior trim. (There may or may not be a key cylinder in the trim.)

- Power supply/controller for delayed egress devices with fire alarm interface and security interlock relay board

- Proximity reader, perhaps utilizing software on the hospital network and Power Over Ethernet

The levels of function I have just outlined on this pair of doors, from simple to complex, are:

- A mechanical locking system

- An electric release system

- An electromechanical door opening system

- Microprocessor control with timer and fire alarm interface

- Software

Basically, the system would work like this:

Case 1: When an ambulance backs up to the doors, the EMT activates the doors using their remote. The presence sensor in the opening prevents the doors from closing until it senses the opening is clear.

Case 2: A hospital employee places his proximity card credential near the proximity reader. The electric mortise lock delayed egress exit device is released and the employee turns the lever and enters. The door closes hydraulically behind him.

Case 3: An unauthorized person attempts to exit. They press on one of the exit devices for two seconds, despite the warning signage, and the device goes into full alarm. Security personnel have fifteen seconds to confront the unauthorized person before the delayed egress system lets them out according to life safety code.

Case 4: A non-fire emergency necessitates the evacuation of the emergency room. A receptions or security guard activates a switch and the doors swing open.

Case 5: The fire alarm is activated. The delayed egress system is deactivated and people can exit freely. The door may remain locked from the outside or may fail safe - be unlocked from the outside - in the event of a fire alarm if local authorities require it by choosing either a fail safe or fail secure electric mortise lock for the mortise exit device.

Case 6: In a complete power outage, the door may be locked or unlocked from outside (depending as above on the choice of a fail safe or fail secure mortise lock). If fail secure there may be entry by key. The delayed egress exit devices now act as simple mechanical exit devices, allowing free egress.

Perspective

From a door hardware salesperson's and buyer's perspective, this means that more questions need be asked, which in turn means that the salesperson needs to know (or have access to) more answers. Secondly, because door hardware installation often involves hardware, electricity and software, the division of responsibility between the trades is also often complex. Today it is difficult to be a locksmith without a low voltage license in many states, and systems integrators are finding themselves installing more and more locks. The different skill sets of those installing hardware mean that door hardware salespeople must often compensate for the lack of knowledge of the installer, educating them as necessary so that they can successfully install the hardware they may buy.

Similarly the buyer of door hardware must also ask more questions about hardware (and perhaps software) and how different components affect the operation, safety and security of a door and must be prepared to listen to the answers. Because the operation of a door can be so complex, great care is needed in hardware selection.

The installer or installers of door hardware must understand how each component works in order to assure that in the end the whole system works correctly. In the system above, an installer working alone would need expertise in electricity, locks, electronics, access control and would also need at least intermediate level computer network skills. Usually, in a project like the one above, a group of installers, each with a different skill set, must work together. Then, coordination and division of responsibility becomes a challenge.

Yes, doors today are often more complex then they used to be. Approach with caution and an open mind.