The right way, to strip, neutralize, and apply wax to vinyl tile!

Vinyl Composition Tile!

Vinyl flooring of all types is comprised of colored polyvinyl chloride chips manufactured into sheets of various thicknesses, most commonly 1/8th inch, which can then be formed into rolls for use on large areas, or cut down into individual sized tiles.

These sheet goods and tiles have many and varied uses. Anywhere a long lasting, easy to clean, neat looking, floor is needed. Interior large open areas and building hallways are very common uses. Also any place that may require a little flex, as Vinyl Tile is the only type of tile that has any flex to it. Installation is fairly easy and can be mastered in a short time. Low in cost and long on durability are the hallmarks of VCT. Vinyl tile has a very high resistance to repeated abrasion and has better impact damage resistance than ceramic tiles. They require wax to provide a good looking surface but this can be stripped and re-waxed repeatedly with no long term effect at all.

Cost for Materials and Installation!

The price of VCT Tiles start at about .82 cents per square ft. to several dollars per square ft. Premium vinyl tiles are listed in the $2.00 to $4.00 range and incorporate a variety of unique patterns and styles. The vinyl industry has made it's product modern and is comparable to all other floor finishes, to include wood, ceramic tile, and stone. Some products may have anti slippage qualities. At the high end of the market are the Static Dissipative Tiles. These SDT, special purpose products are normally installed in areas of electrical sensitivity. This tile is designed specifically to eliminate any static charge that may be damaging to the electronics in a specific space. These tiles are at the high end of the market and are priced at $5.00 to $6.00 dollars per square ft. Tile comes in boxes of 45 Sq. ft. per box.

You can buy off the shelf or you will find a much larger selection on the net. Measure your space and add about 15% extra for waste, when you order.

In addition to the tiles themselves you will require latex adhesive. Ensure you get the correct product for Vinyl Tile. One gallon covers about 200 sq. ft. and costs about $20.00.

The Price of Labor for the installation of VCT is about $3.00 to $5.00 per ft. This price range is dependent on several factors.

1. Location - Driving Time.

2. Room Size

3. How thick is the wax that needs to be removed?

4. How much edge work?

5. Number of finish coats.

6. Fixtures to work around.

7. Steps, or individual pieces to be completed by hand.

8. Set Up time. Is it ground level or upstairs?

9. Parking

10. Moving furniture

Note:

The materials price listed above are for the square foot tiles. VCT is also manufactured in 16" x 16" and 12" x 24" sizes for commercial application. Boxes of these larger sized tiles are very, very heavy so expect to pay a slightly higher delivery fee than normal. It's worth every penny though, as these tiles are not for the do it your self-er.

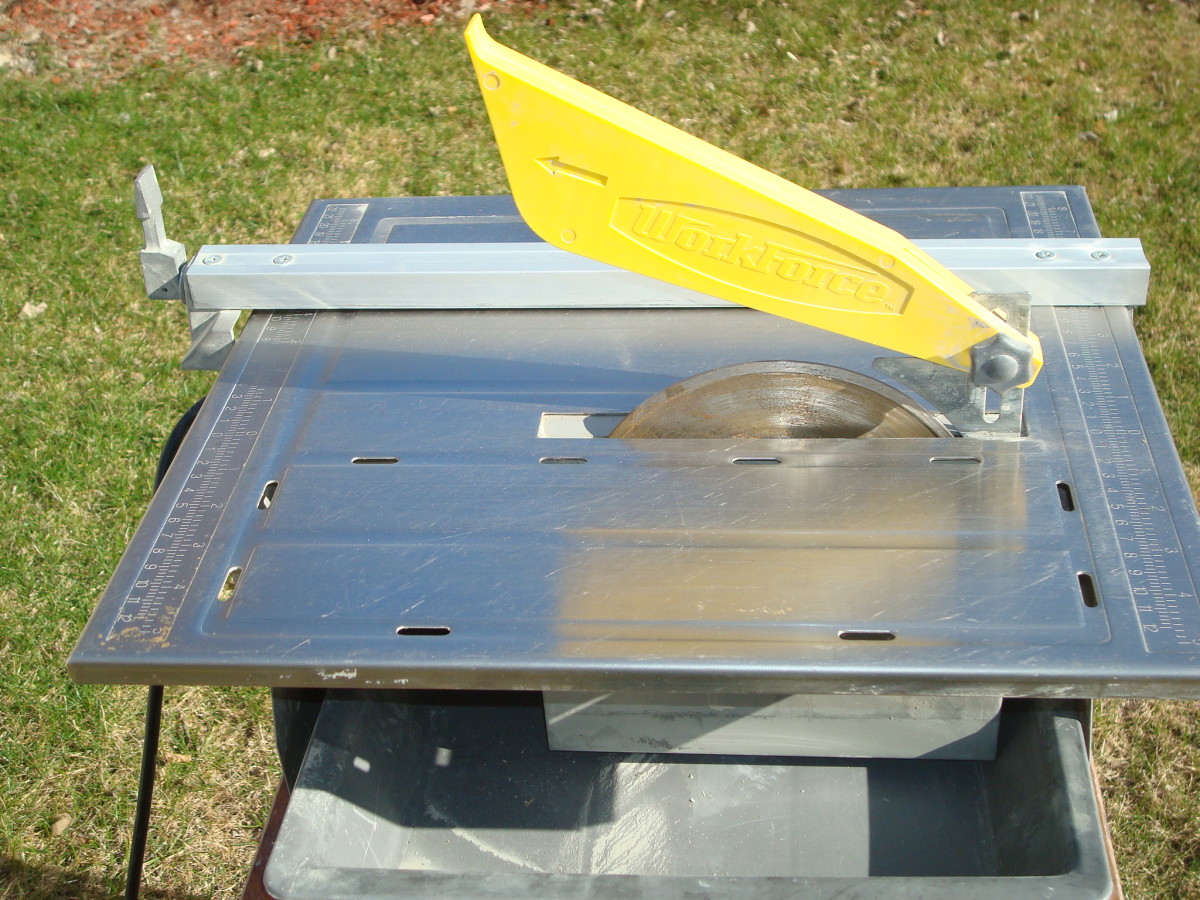

Versa Pro Rotating Floor tool!

Turbo, Hard Surface Spinner Tool!

Stripping Vinyl Tile

Most of the tile you will purchase comes with a light, low grade wax coat, installed by the manufacturer to protect it until a professional waxing can take place. After the new tile has been installed allow the 2 week time period that is recommended by most manufacturer's, and is needed for the curing of the tile adhesive. This ensures that there will no problems with the tile coming loose while wetting the floor with the water/stripper solution during the initial stripping process. Follow these same instructions for stripping your vinyl floor at home. It will work for you whether it is this initial stripping and re-coating, or for the 50th time you are completing this task.

Floor stripping is the process of completely removing all traces of wax, dirt, and debris from the floor surface. Don't fool yourself, if you have never completed this task, it is very labor intensive, and time consuming. Post safety cones or signs in the access areas to where you are working. First sweep the floor of all dirt and debris. The cleaner the floor is that you start with, the cleaner the floor will be that you finish with. Use only products that designed for use on vinyl tile. Stay in the same family of products for the stripping, waxing, and also the maintenance phases of your flooring.

Mix the stripper according to directions. There are several ways to distribute the stripper onto your surface. Mop and bucket, small spray bottle, or the 2 and 3 gallon pump sprayers. Make sure that all the materials you bring into the stripping area are clean on the inside and outside so as not to transfer any dirt or unknown chemicals onto the floor. Pay attention to whether the stripping product calls for using hot water or cold water, and make sure to use the proper stripper to water mix ratio. Pouring straight stripper onto the surface will not do a better job than the proper recommended mix, and it might even cause damage to the tile, or loosen the adhesive.

Apply the Stripper, using the chosen tool. Allow for a dwell time of 5 to 10 minutes, check the product label for the dwell time of your specific stripper product. Try to apply enough stripper to do the job without the stripper drying up, before you have allowed for the dwell time and then completed the mechanical stripping. The only real way to know this is through experience. If you are not using enough stripper solution, it dry up while you are operating the Rotary Floor machine. This is because it is taking more stripper product to breakdown the layers of wax than what is available to do the job. Do not allow the stripper to dry. Work in an area the size of which you can manipulate the Rotary Machine within a time frame that you will finish the mechanical stripping without the liquid stripper dying up. We find it best to spray the stripper on an 8' by 8' foot area to start, and then adjust to a larger or smaller area as needed. This will depend on how many layers of wax are being removed, the temperature, and any air movement. You may keep the air conditioning on during the stripping phase, but we shut the air off and close any doors adjacent to the area when applying the wax.

The Stripping of Floor Wax is completed using a combination of the liquid stripper and a Mechanical Rotary Tool. Then using a Spinner tool to rinse and extract. Make sure and use defoamer in your Truck tank, or wet vac system as stripping creates a lot of foam. We prefer to use a two man operation. There are 2 basic functions that are started at this time. The agitation process is started first and then the rinsing follows. After the stripper solution has been allowed to dwell for 5 or 10 minutes, the first person starts agitating the stripper using the Versa Pro Rotating Flooring tool (our choice). We like to let the person completing this part get a few feet ahead and then the second person starts using the Spinner Tool to extract the stripper and wax, now turned into a liquid slurry mixture. After he has sucked up this slurry mixture he then visually inspects the now stripped surface to see if all the wax has been removed. Any remaining wax is usually easy to spot as it looks different from the freshly stripped areas. It will be darker and have a slight yellow tint to it. If not all the wax came off the first time then another pass using the same procedures is in order. Spray stripper, allow to dwell, use rotary tool and then extraction tool. After ensuring all the wax has been removed the second man sprays a light coat of PH - neutral cleaner onto the surface. This cleaner does not require a long dwell time and is removed by using the spinner tool.

All the edges and any steps must be hand stripped. The is the down on your knees work. Complete this portion of the job using a spray bottle and a hog hair pads. We use the thin scotch brite pads, that can be purchased at the grocery or hardware store. Doddlebug pads work good also. Be detailed in your work. Ensure you run the spinner tool along these edges after you have completely removed the wax, and clean using the neutral PH cleaner. This completes the stripping process. Strategically place fans or air blowers on the floor to accelerate the drying process. A Gekko tool can be used in place of a spinner, and a wet vac is a good third option.

Note: Sometimes it may be tempting to skip using the neutral PH cleaner. But I caution, do not skip this important step. If the PH of the floor is too high from using stripper, the sealer/finish may not bond to the floor, or it may prevent proper curing of the finish coat. Additionally, there may be clouding and hazing in the finish, so always use the neutral cleaner/neutralizer.

Padco Pads! What the Pros use!

Applying the new Wax to your floor!

Always apply 2 coats of wax to a freshly stripped floor. Thin coats are always to be applied to VCT, never thick coats. Thick coats may have problems drying properly, There is never any need to put more than 3 coats on a newly stripped floor. When I hear someone say they have put 5 or even 7 coats of wax on a newly stripped floor it is from lack of knowledge about what they are doing and they can never give a satisfactory answer as to why they did this. Apply at least 2 and maybe 3 coats and never any more.

Close all the windows and doors if there is any measurable amount of wind coming through them that may be carrying debris from the outdoors. Shut the doors and turn off the ventilation also. Do not take any chance of debris sticking into your wet wax. Strain your wax using a section of chees cloth or a designated strainer as most often there will be bits of dried wax inside the container and you cannot allow these to dry on your freshly waxed surface. These are especially found in the 5 gallon cans the pros use.

When applying wax remember a little goes a long way. Use a clean (or new) rayon mop, a padco pad, or a micro fiber applicator pad to apply your wax. Some people say to use a new mop head or pad every time, but thats not true. What is true is that most people do not take the time to clean out their mops or applicator pads properly. So for them, they must use new ones. For the rest of us, who know how to clean them, using one that is already broken in is fine. When applying the wax it should go on the flat surfaces only. NEVER ON THE BASEBOARDS. Be very detailed in your application technique. Do not splash wax, or stripper for that matter, on the walls, or rub along the baseboards. Apply wax in thin coats. Allow plenty of time to dry between coats. Do not use fans to dry wax, just allow wax to air dry. Work the room so you will finish at the exit.

If your tile is older than 1980 it may have Asbestos, if you suspect that your home or business has asbestos tile please check out this link:

- The Original Vinyl Composition Tile (VCT) – Asphalt & Asbestos Tile Flooring

Asphalt & asbestos tile flooring, early forms of Vinyl Composition Tile (VCT), was a popular flooring choice into the 1980s.