Electrical Resistance Heating Environmental Remediation

Electrical Resistance Heating (ERH) Environmental Remediation

A Look At Electrical Resistance Heating (ERH) Environmental Remediation

Traditional soil and ground water environmental remediation methods, such as soil excavation that involves off-site disposal and ground water treatment systems (e.g., pump and treat or air stripping), are not only expensive, but can also be very disruptive to a property that has building on it and is being actively used. While disruptive environmental remediation methods can be tolerated on fallow brownfields sites that are not being used by anyone, they are very cumbersome and sometimes entirely impractical for properties with commercial or residential buildings on them. For active sites, Electrical Resistance Heating (ERH) is a remediation option that should be taken under consideration.

Necessity is the mother of all invention. In response to physical site constraints, the environmental remediation field has developed a number of in-situ (in place) remediation methods that are non-disruptive and often are not even noticeable to property occupants, yet are still capable of cleaning up contaminants beneath polluted properties to safe levels below regulatory thresholds. One of these in-situ remediation methods is Electrical Resistance Heating (ERH), which utilizes alternating current (AC) electricity to heat volatile organic compounds (VOCs) and semi-volatile organic compounds (SVOCs) contaminated soil and ground water, which causes contaminants to evaporate, reducing their concentrations.

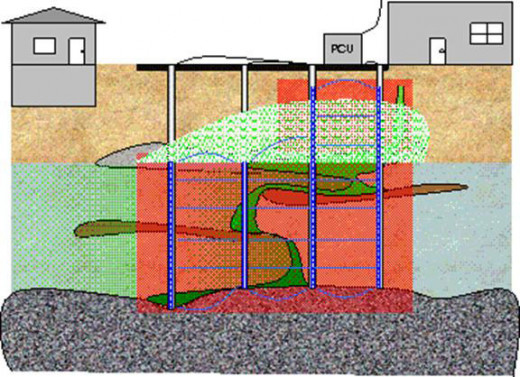

How Electrical Resistance Heating Looks Underground

How Electrical Resistance Remediation Heating Works

Electrical Resistance Heating remediation involves passing an electric current through a soil or ground water contaminant area. This is done by installing subsurface electrode elements that facilitate the flow of electrical current through the contaminant area. The soils and ground water in the contaminant area naturally resist the electrical flow, which causes the soils and ground water to heat up. The goal is to heat the ground water in the contaminant area to the boiling point, which causes the ground water to change from the water phase to the gaseous phase, which causes VOCs and SVOCs contaminants to be liberated from the soil and ground water, thus reducing their concentrations in the subsurface soil and ground water contaminant area.

The liberated VOCs and SVOCs vapors naturally move towards the surface; however, since timely remediation is required for sites with buildings on them, vapor removal must be enhanced and accelerated. The accelerated removal of vapors from the subsurface is done by utilizing Soil Vapor Extraction (SVE), which involves the installation of subsurface wells or use of existing subsurface wells to apply a vacuum to the subsurface to draw out vapors. The vapors are then treated at the surface in accordance with pertinent environmental regulations.

Electrical Resistance Heating also enhances and accelerates the natural degradation of VOCs and SVOCs contaminants by speeding up naturally occurring bioremediation, as warmer subsurface temperatures allow subsurface contaminant eating microbes to multiply readily, and by enhancing hydrolysis and iron reductive dehalogenation, which both naturally reduce contaminant levels in the subsurface.

While removal of VOCs and SVOCs contaminants is desirable, since it reduces their concentrations in the subsurface soil and ground water contaminant area to safe levels below regulatory thresholds, it can cause VOCs and SVOCs vapors to enter buildings and structures at the surface, if they do not have properly installed vapor barriers. This is a short term concern since upon completion of the Electrical Resistance Heating remediation, temperatures in the subsurface gradually return to normal and any residual VOCs and SVOCs vapors are greatly lessened or eliminated since the VOCs and SVOCs source of the contamination in soil and ground water beneath the site has been addressed and contaminant levels have been greatly reduced.

To adequately protect building occupants during Electrical Resistance Heating remediation, positive pressure should be established in buildings on the property to ensure that vapors do not enter buildings and a High Efficiency Particulate Air (HEPA) filtration system with activated charcoal filtration should be utilized within buildings to further ensure indoor air quality is not affected by the remediation.

How Electrical Resistance Remediation Is Being Used

Electrical Resistance Heating is most often used on sites with buildings on them since removal or treatment of contaminants by other means is often not possible without removal of the building structures. The most typical Electrical Resistance Heating remediation goal is the reduction of chlorinated VOCs contaminant levels that are dense non-aqueous phase liquids (DNAPLs) and petroleum hydrocarbons that are light non-aqueous phase liquids (LNAPL). Chlorinated VOCs are most often associated with solvents that are used for a variety of industrial and commercial purposes, including dry cleaning.

While Electrical Resistance Heating cannot be utilized on all contaminated sites, due to site-specific conditions that are unfavorable, Electrical Resistance Heating has proven to be highly effective at reducing VOCs and SVOCs contaminants to safe levels below regulatory thresholds at thousands of sites across the United States. The effectiveness of Electrical Resistance Heating remediation is assessed by collection of post-treatment soil and ground water samples. Electrical Resistance Heating is particularly useful at sites where buildings or other structures limit treatment options and a non-disruptive in-situ treatment method is necessary to remediate the site without disturbance to site occupants.

Guaranteed Remediation in Soil -- 3D

© 2011 John Coviello