- HubPages»

- Fashion and Beauty»

- Clothing»

- Costumes & Uniforms

Understanding Silicone Gaskets

Medical Silicone Gaskets

What is a Silicone Gasket and how is it used?

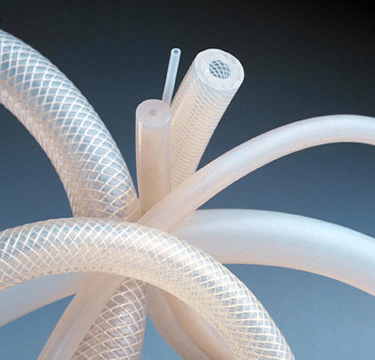

A gasket provides a seal between two surfaces to prevent leakage of fluid or air when the devices are under pressure. You will find gaskets in systems that have water or other fluids under pressure, such as hoses, automobiles, air compressors, fluid delivery systems and even in electrical systems when an electrical system is underwater or could be exposed to moisture and needs to be protected.

Silicone is an ideal material for gaskets because it functions in a wide range of temperatures, is UV resistant, is non-reactive with fluids, especially fluids that would corrode or damage other material over time and it has a high compression value, one of the highest available. Silicone gaskets can also be developed and produced with exacting specifications quickly and cost effectively.

Types of Silicone Gaskets

There are a number of techniques for producing silicone gaskets including gaskets that can be cut from sheets of silicone. The silicone can be cut using a die or with a water jet. Gaskets can also be produced using injection molding (e.g. see rapid prototyping from Albright Tech), compression molding or transfer molding. Injection molding could be the preferred method of production when sealing integrity needs to be very high for water tight specifications and requirements. Silicone gaskets can also be produce from sponge and foam. The best production method is selected based on the use for purpose and mechanical specifications for the gasket.

When the consequence of failure of the gasket is high, specifications can be increased so that the silicone gasket used will be more durable, fit tighter, last longer and prevent the risk situation from happening. Some examples are critical mechanical applications or electrical systems that must be safe from moisture to prevent shorting or electrical energy from entering areas that could harm people, equipment, animals and such. The environment where the silicone gasket is to be used also needs to be considered, since exposure to UV rays, high temperatures or caustic materials needs to be part of the specifications to produce the best silicone gasket possible for each application.

Gaskets are often taken for granted, until they fail. When a gasket fails the process stops, whatever that might be. Choosing the best, most durable gasket for the application will deliver the most trouble free and longest service life possible. Choosing the correct, high quality silicone gasket is a very important part of making sure things work as they should.