3D Printing in a Nutshell

A New Dimension of Creativity

Since the advent of personal manufacturing technologies, innovators and tinkerers have relished their ability to create products in the comfort of their respective abodes. Today’s manufacturing processes are only limited by the imagination of their implementer, and 3D printing is chiefly accountable for this convenience. While 3D printing is an ongoing investigation of the bounds of technological creativity, it leaves behind a legacy which inspires innovation in a diverse range of applications.

The goal of 3D printing is to facilitate the creation of objects that cannot be normally manufactured. Originally, the technology was only seriously considered in manufacturing, architecture, and engineering design applications as a means of easily and cheaply creating prototypes and models; however, today’s innovators recognize the immense benefit and convenience of 3D printing. With innovations in the field of additive manufacturing, operators of 3D printers are able to manufacture custom parts on a desktop, while teams of scientists are able to manufacture living tissues in a laboratory.

How We Got Here

The first use of what we now term 3D Printing was in additive manufacturing processes used for rapid prototyping. Additive manufacturing is a process in which layers of a desired material are added together to form a solid object. With respect to design, the additive process allowed manufacturers to use computer aided design (CAD) software to design and “print” desired objects.

Historically, the first implementation of 3D printing was at 3D Systems, a manufacturing corporation in Rock Hills, South Carolina. 3D Systems set out to prove the feasibility of rapid manufacturing and prototyping using additive manufacturing. In 1984, 3D Systems was the first to successfully demonstrate that highly complex designs could be manufactured overnight. The commercial release of their first 3D printer in 1989, which utilized a method coined stereolithography, put 3D Systems at the forefront of 3D printing innovation. While the technology was originally intended to optimize prototyping technology, commercial manufacturers began pushing the envelope with versatile new materials that could be “printed” and used as end products.

In general, any method that can automatically construct a 3-dimensional object constitutes 3D printing. Different applications and different outcomes call for varied 3D printing technologies and methods.

Stereolithography

Stereolithography (SLA), the aforementioned pioneering technology developed by 3D Systems, uses a computer-guided UV light to selectively cure a plastic material. Stereolithography prints 3D designs by curing certain shapes onto layers of plastic, and then stacking these layers to form a 3D object, effectively “printing” layers of the final product. SLA was the earliest form of 3D printing from computer-designed models and was inspired by common, inkjet printers.

Selective Laser Sintering

Selective Laser Sintering (SLS) requires a reservoir of a specially produced powder material. Beginning with a thin layer of the powdered material, a high powered, computer-guided laser scans the surface, melting and fusing the powder to form one layer of the printed object. The apparatus then adds a layer of powder and continues to selectively fuse successive layers of the 3D object. The laser effectively fuses each layer of solid material to form a 3-dimensional solid which must be dug out from the surrounding loose powder and cleaned with a high-pressure air compressor.

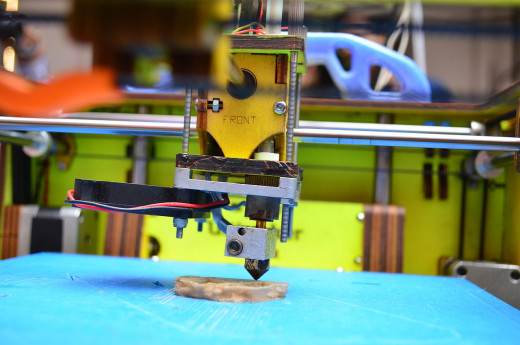

Fused Deposition Modeling

Fused Deposition Modeling (FDM) works like a combination hot glue gun/ink jet printer. It prints melted material (normally plastic) that is designed to quickly dry from a nozzle in successive layers. This technique produces versatile and strong designs and is used in many industries for high precision results (high-end product manufacturing, and biomedical manufacturing). 3D Systems likewise pioneered this technology with their release of Multi-Jet-Printers (MJP) in 1996, which allowed multiple materials to be printed simultaneously. Bioprinting methods mostly use technologies based on FDM, with the exception of printing cells as opposed to plastic polymers.

Jetted Photopolymer

Jetted Photopolymer (JP or Polyjet) ejects photopolymers, which are hardened with UV light. The process is similar to FDM, but allows for a greater range of material properties (such as flexible plastics and rubbers). While FDM may produce highly durable, highly accurate parts, JP or Polyjet prints can produce a high level of detail and greater adaptability with materials and surface effects.

Generally, technologies of 3D printing vary largely, but are likened by their functions to produce a 3D printed product from digitally created models. While engineering design and manufacturing applications most commonly utilize 3D printing today, many innovators in the field agree that bioprinting is one of the most important prospects of the manufacturing industry. And while the bioprinting frontier has yet to blossom, current medical applications are becoming widely used to utilize the accessibility and convenience of 3D printing technology. Bioprinting can be described simply as the 3D printing of parts meant to be utilized in biological systems; these can further be classified as inanimate and living parts.

Bioprinting

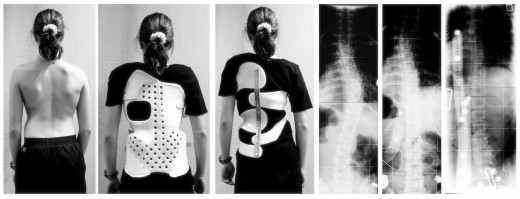

Orthoses, or corrective orthopedic braces) have long been sold under one-size-fits-all or custom-made (read: pricey) models. Since everyone’s bones are unique, it has never been thought feasible to create custom orthoses for every patient. However, with the development of 3D printing technologies, a 3-dimensional scan of the body allows orthopedic specialists to design and manufacture custom orthoses for all and sunder. Custom orthoses, which are comfortable and greatly effective, are now more accessible to patients dues to the availability of 3D printing technologies. In addition, orthopedic specialists are now able to make improvements to decades-old orthosis designs.

Similarly, while one-size-fits-all prosthetics are available, the desire for custom prosthetics has greatly increased in the last decade. Several companies are now using 3D printing technology to create custom prosthetics that fit comfortable and are durable, functional, customized, and aesthetically appealing. Bespoke, a prosthesis manufacturing company residing in San Francisco, boasts that its innovative 3D printed prosthetic limbs “are designed to fit exactly the shape of the wearers’ bodies and lifestyles and to appeal to their sense of style." The company “allows customers to explore a range of design styles, including leg patterns, materials plating, and finishes that give its wearer the same social cachet offered by a racy designer motorcycle or unique tattoo."

Additionally, bones can now be printed in titanium -- which is an ideal material because it is biocompatible -- for custom bone replacement. This was especially useful in replacing bones for victims of bone cancer. Orthoses, prosthetics, bones replacements, and other inanimate biological parts are all inanimate parts that are important in proper biological functioning.

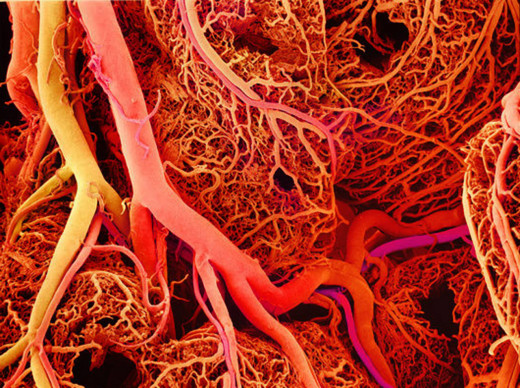

One example of living parts bioprinting is the printing of live cells. This technology is at the forefront of innovations in biotechnology and scientists believe it will allow medicine to transcend its current limitations. One method, similar to FDM, prints individual cells from a live cell reservoir into a medical gel, called Hydrogel, that holds them in place. With the ability to synthesize cell structures using a printer, the bioprinting embraces a frontier of medical and biological innovation. By printing lattices of active and responsive cells, scientists have successfully synthesized functional tissues, blood vessels, cartilage, and bones.

Researchers can now examine the experimental bioprinting of blood vessels. While such an application is still under examination in terms of feasibility and is far from perfect, scientists were able to print -- under incredible laboratory conditions -- blood vessels that successfully carried blood from the heart. Cartilage printing has been an important mediation of engineering and orthopedic medicine for more than 5 years. Aside from prosthetic cartilage and cartilage-like joint replacement, 3D printing applications now allow orthopedic surgeons to bioprint actual cartilage -- including necessary cells that adhere to neighboring bones -- straight into the joint in a surgical procedure. This remarkable method allows for the greatest precision and efficacy in replacing cartilage and preventing abrasive joint replacements.

What's Next?

While many goals of 3D printing have a long way to go before becoming a reality, the currently available technology seems science fictional. With the aforementioned technologies, 3D printing can already be used to manufacture most things imaginable. Today’s manufacturing is only limited by human creativity; nonetheless, 3D printing has realized many creative designs and imaginative concepts. For example, 3D printing has recently entered the arena of food production, where the available technology is utilized to “print” food substances that are tasty and nutritious. Equally creative is the technology’s applications in realizing wild and otherwise unfeasible architectural designs. Several Dutch architects, who collectively make up DUS Architecture, have perfected the process of cheaply printing modular homes to provide a high-tech housing solution in underdeveloped countries -- the materials for these prints come entirely from recycled goods and the printed product is fitted together with a nod to Lego. Thus, 3D printing technology is an effective method of manufacturing that has penetrated nearly every production industry by facilitating the creation of nearly anything.