A New Direction in Biofuels

Biofuels

Introduction

Advanced biofuels have recently been introduced into the fuel sector as alternatives to foreign oil. Algal biomass is the most productive in manufacturing biofuel which can be utilized as fuel for motor vehicles and jets. Secondly, ethanol produced from corn is the second best option for commercialization and is currently in the gasoline market as an ethanol/gasoline mixture for motor vehicles. Although, ethanol can also be produced from cellulosic biomass. Cellulosic ethanol requires further research, but as of 2014 will be produced on a commercialized basis for the first time.

History

During 1973-1974 the Organization of Petroleum Exporting Countries (OPEC) imposed an oil embargo against the United States of America and other countries [1]. This oil embargo caused a crisis in the United States, and in turn created incentive to pursue biofuels in order to be independent of foreign oil. Today in 2014, dependence on foreign oil is still a concern as well as climate change. Therefore, biofuels became a viable solution to these problems by lowering carbon dioxide emissions and growing feedstock material domestically instead of outsourcing to other countries. By doing so, the opportunity for job expansion and economic growth is a possibility.

In 1992 the Energy Policy Act was legislated [2]. This act mandated that automobile makers, create and make available to the public, vehicles that could use alternative energy such as ethanol. This added to the incentive to continue research and investment into the idea of biofuels being a viable alternative to petroleum. During 2007, “The Energy Independence and Security Act (EISA) required the incorporation of 15 billion gallons of ethanol into the fuel supply by 2015 and 36 billion gallons by 2022 [2].”

So Green:Algal Biomass

Algal Biomass

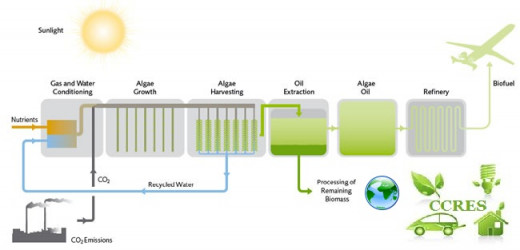

Algal biomass has been a recent “advanced biofuel” that is currently being researched and implemented by companies such as the National Renewable Energy Laboratory. Algae is a suitable “feedstock” because it can multiply rapidly. It only requires sunlight, inorganic nutrients and carbon dioxide in order to be converted into biofuel. Depending on the type of algae, for commercialized uses the algae can use waste water or sea water to grow [3]. Sea water is abundant in the world and using waste water is a great way to reuse a by-product of many industrial processes. An overall process flow diagram can be seen below [4].

Algal Biomass Process

In the Figure above, the “biomass to biofuel” process requires carbon dioxide. Carbon dioxide is a by-product of many industrial processes and by utilizing it, emissions in the air will be reduced. The algae could be grown in ponds or storage containers called photobioreactors and depending on the strain of algae, the nutrients involved sugar or starch for fermenting purposes.

Further research is required to discover the right algae strain that would be the most economical option in biodiesel production but according to an algae industry survey taken in March of 2014, “algae-derived fuels are likely to be price competitive with fossil fuels by 2020 [5].” This survey was conducted with over 280 responses from the industry and 83% of these responses were in agreement with this statement. The price per gallon of algal fuel was approximated to be less than $5.00 by 2020. Currently on average the price for unleaded gasoline is $3.09 per gallon in Colorado, $3.38 per gallon in California and $3.39 per gallon in New York [6]. Algal fuel would be competitive at under $5.00 per gallon during the summer months in the U.S when gasoline prices rise up to approximately $4.00 in places like Colorado. Although, by the year 2020 gasoline prices could rise or fall depending on petroleum production and could place biofuel in the motor vehicle fuel market.

Commercial Scale: Algal biomass

The “EPA is proposing to maintain the biomass-based diesel standard for 2014 and 2015 at the 2013 level of 1.28 billion gallons [7].” This amount was exceed in 2013 where, “The U.S biodiesel industry produced more than 1.8 billion gallons of fuel [8].” Therefore, reaching the 1.2 billion mark is a realistic number. It can be consistently reached in 2014 and 2015 as long as feedstock and nutrition resources stay viable.

Currently algal biomass is being produced but not to its full potential. Biofuel from algal biomass is still currently being researched to enhance production on a commercial scale as well as enhancing ways to separate the biomass from the oil (fuel) and drying the biomass. Separation is the most important part of any biological process and some common ways for separating the biomass include, ion exchange, membrane separation, distillation and chromatography.

Ethanol

Ethanol

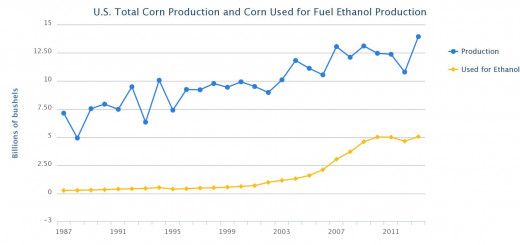

Ethanol in the United States is mostly produced from corn. Ethanol can be used as a fuel for motor vehicles and reduces carbon dioxide emission that are a by-product of non-oxygenated fuels. One of the main concerns about ethanol being produced by corn is that the production will limit the food supply. Figure 2 shows the amount of corn produced and how much of that corn is used to produce ethanol from 1987 to 2011 [9].

Stats

Seen in Figure 2 above, corn production has increased from approximately 7.5 billion bushels to approximately 14 billion bushels from 1987 to 2011 respectively. The production of corn used for ethanol increased to approximately 5 billion bushels of corn in 2011. Therefore, half of the amount of corn produced in 2011 went into the production of ethanol. Although, studies suggest that, “In fact, data compiled by the USDA for 2012/13 indicates that only 4.67 billion bushels of corn or 39% from a total supply of 11.93 billion bushels was used for ethanol and by-products [10].” Thus, the corn usedj to produce ethanol did not exceed the amount of corn used for the food supply in the last 2 years.

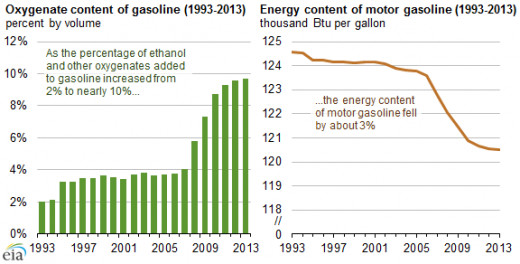

For each gallon of gasoline used in vehicles a blend of 10% ethanol by volume is used [11]. Another main issue with ethanol is distribution. Most of the ethanol is produced in the Midwest and must be transported around the US. The most consumption occurs on the East and West coast states. Using pipelines normally used for fossil fuels distribution would be the most desired method of transporting ethanol. Although, a major problem with this system, is that hydrocarbons may leave behind residues and the ethanol (a solvent) could mix with these unwanted residues or also mix with water left behind, and could have a different specification once it reached its destination [11]. Proposed solutions were to clean the existing steel pipelines thoroughly, and also adding in an anticorrosion chemical to ensure that the pipeline would remain intact for a good duration of time. Figure 3 shows the effects of ethanol and other oxygenates (additives to gasoline that have oxygen as a product) on motor gasoline energy content [12].

The data in Figure 3 shows that since 1993 the use of ethanol and other oxygenates being added into gasoline for motor vehicles has increased from approximately 2% by volume to 10% by volume by 2013. In turn, this increase in oxygenated content has decreased the energy content in the gasoline in motor vehicles. Due to the lower energy density in the gasoline, the vehicles get less miles to the gallon which is another downfall in the eyes of the consumer, who would have to fill up their gas tank more often.

Another issue in ethanol production, is the production cost. In order for ethanol to be equivalent in energy as a gallon of gasoline, it would cost $1.65 to produce a gallon of ethanol whereas for gasoline it would cost approximately $0.90 to produce one gallon. In order to overcome the cost issues, Oregon provided subsidies that permit the production of ethanol. These subsidies allow ethanol mixed gasoline to be 5.4 cents less in taxes than that of gasoline alone [13]. The ethanol-gasoline mixture is 10% ethanol and 90% gasoline. Thus ethanol is a part of the competitive market and is produced and sold to consumers for motor vehicle use.

Switchgrass for Cellulosic Ethanol

Cellulosic Ethanol

Cellulosic ethanol is a type of biofuel that requires a plant material called lignocellulose. Lignocellulose makes up most of the structural parts of a plant. It can be found in wood chips, trees, and switchgrass. The most currently studied material is switchgrass. Switchgrass can get up to 10 feet high and is a tough type of grass that can grow rapidly [14]. It is also more drought resistant that corn. Thus, why it is of such interest.

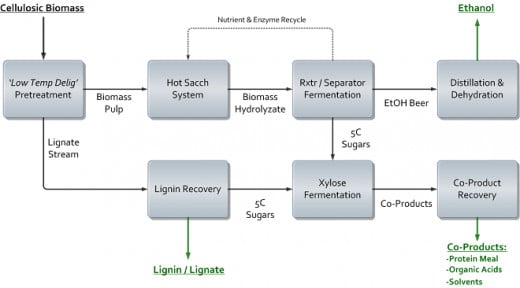

Cellulosic Ethanol Process

Cellulosic biomass is fed to the process in Figure 4, and multiple products are available for production. As shown above products such as solvents, and organic acids are produced as byproducts and can be utilized in other processes.

The Future

Commercial Scale: Cellulosic Ethanol

Research on the commercialization possibilities of cellulosic ethanol has been ongoing since 2011 for the company DuPont. They have created a program that allows a collaboration between farmers and researchers to further study this biofuel possibility. According to their findings, current switchgrass yields range between 4 and 12 tons. Although, they estimate that the ethanol yield per dry switchgrass could be more than 6 billion gallons per year in the United States [15].

This year (2014) the first commercial scale cellulosic ethanol facility will be operational. It is located in Nevada, Iowa and DuPont estimates the facility to produce 30 million gallons of ethanol per year. In order to produce this amount they estimate to consume 700,000 corn stover bales per year [16]. Storage for the switchgrass involves the cooperation of over 500 farms. The cellulosic ethanol business could provide many jobs, reduce the dependence the United States has on foreign oil and utilize unwanted or harsh soil areas not suitable for cultivating food crops.

Conclusion

Biofuels have become a desirable alternative to foreign oil. Advanced biofuels such as algal biomass have recently become commercialized and continue to be supported by private companies and government funds to continue researching different strains of algae that are the most desirable and will produce the most biofuel. Ethanol production from corn stocks is also a suitable alternative. Currently gasoline mixed with ethanol is sold to public consumers to use in their motor vehicles. Tax breaks for the ethanol/gasoline mixture allows for ethanol production to compete in the fuel market alongside petroleum products. Although, Cellulosic ethanol is another suitable alternative. It is produced from plants containing lignocellulose and the most economical choice of material is switchgrass. In 2014, commercialization of cellulosic ethanol is a possibility due to the company DuPont and companies like them. Cellulosic ethanol is an alternative to ethanol production that is conventionally made solely from corn.

Variety it the energy sector encourages competition. Inspiration and entrepreneurship comes out of competition and will further research in biofuels. This in turn, provides the opportunity for creating new jobs in the United States. Overall, biofuels utilize domestic material that can be grown in the United States and can reduce the dependence on foreign oil, and in the case of algal biomass, reduce carbon dioxide emissions in the air.

Feedback

Would you like to see information on similar topics in the future?

Resources

Resources

[1] Office of the Historian “Oil Embargo, 1973–1974.” Internet: https://history.state.gov/milestones/1969-1976/oil-embargo, Oct 31, 2013 [Oct. 28, 2014]

[2] RP Siegel, “A Brief History of Biofuels.” Internet: http://www.triplepundit.com/2012/10/history-of-biofuels/, Oct. 1st, 2012 [Oct. 28, 2014]

[3] “Microalgal Biofuels Capabilities.” Internet: http://www.nrel.gov/biomass/microalgal_biofuels.html, Dec. 20, 2013 [Oct. 28, 2014]

[4] “CCRES ALGAE TEAM.” Internet: http://ccres-aquaponics.blogspot.com/2012/10/ccres-algae-team.html, Oct.18, 2012 [Oct. 28, 2014]

[5] “2014 Algae Industry Survey.” Internet: http://www.algaebiomass.org/resource-center/references/industry-statistics/, March 2014 [Oct. 29, 2014]

[6] “Show Average Prices By Metro Area.” Internet: http://www.coloradogasprices.com/Prices_Nationally.aspx, Oct. 29, 2014 [Oct. 29, 2014]

[7] “EPA Proposes 2014 Renewable Fuel Standards, 2015 Biomass-Based Diesel Volume” Internet: http://www.epa.gov/otaq/fuels/renewablefuels/documents/420f13048.pdf, Nov. 2013 [Oct. 30, 2014]

[8] “What is Biodiesel?” Internet: http://www.biodiesel.org/, 2014 [Oct. 29, 2014]

[9] “Alternative Fuels Data Center.” Internet: http://www.afdc.energy.gov/data/search?q=ethanol, June 4, 2014 [Oct. 27, 2014]

[10] Food Vs Fuel.” Internet: https://mnbiofuels.org/resources/facts-about-ethanol/food-versus-fuel, 2014 [Oct, 27, 2014]

[11] “Algal Biofuels Projects and Partnerships.” Internet: www.nrel.gov/docs/fy10osti/49123.pdf, Sept. 2010 [Oct. 29, 2014]

[12] T. Radich. “Today In Energy.” Internet: http://www.eia.gov/todayinenergy/detail.cfm?id=18551, Oct. 27, 2014 [Oct. 27, 2014]

[13] “Biomass Energy: Cost of Production” Internet: http://www.oregon.gov/energy/RENEW/Biomass/Pages/Cost.aspx, [Oct, 28, 2014]

[14] “Biofuels from Switchgrass: Greener Energy Pastures.” Internet: https://bioenergy.ornl.gov/papers/misc/switgrs.html, [Oct. 29, 2014]

[15] “Energy Crops.” http://biofuels.dupont.com/cellulosic-ethanol/feedstock/energy-crops/, 2012 [Oct, 29, 2014]

[16] ‘POET-DSM, DuPont, Abengoa begin commissioning cellulosic plants.” Internet: http://biomassmagazine.com/articles/10511/poet-dsm-dupont-abengoa-begin-commissioning-cellulosic-plants, June 11, 2014 [Oct. 29, 2014]