Biodigester Production

A STEP BY STEP PROCEDURE OF BIOGAS PRODUCTION

A Brief Introduction:

Biodigester is a form of machine or mechanism, used for the production of biogas, through the anaerobic fermentation of animal dunks, wastes, etc. It can play a pivotal role in integrated farming system by reducing health risks, facilitating the control of pollution and at the same time, adding value to livestock excreta through production of biogas and improved nutrient status of the effluent as fertilizer for fish ponds and crop lands. Energy is also a fundamental factor for economic development, but normally the energetic model are based on “non renewable” resources.

In addition to energy sources from human and work animals like camels, there are many kinds of renewable energy such as hydraulic energy, wind energy, solar radiation or biomass (through pyrolysis and gasification). During the course of this century, the world energy consumption per inhabitant has increased sixteen folds. Today, the industrial countries with 32% of the world’s population consume about 82% of the planets’ energy.

On average, a person from an industrialized country consumes 20 times more energy than a person from Africa. It is clear that the economic development model is what drives energy consumption today.

In developing countries, there is a serious shortage of fuel and the energy crisis is a daily reality for most families. Cooking is one of the most energy consuming activities yet, is often inefficient. The open fire is still very common. Today, the devastation of forest in developing countries is frequently mentioned in the mass media. Deforestation has many causes. Poor people are migrating and inhabiting, cultivating and using New Forest areas. In some cases, they use “slash and burn” method and this is another important cause of deforestation. However, the daily consumption of fuel must not be under estimated when considering causes of deforestation. It is not unusual for a family to have to spend the greater part of their day gathering fuel for their home. At times, dozen of kilometers need to be covered to find fuel (like firewood).

Many developing nations like Columbia, Tanzania, Vietnam, Cambodia, Ethiopia, have promoted the low cost biodigester technology, aiming at reducing the production cost by using local material and simplifying installation and operations. Some of the models used were a continuous flow flexible tube biodigester based on the red mud PVC (Taiwan) bag design.

The History of the Biogas:

In overview, anecdotal evidence indicates that biogas was used in 10th century BC by Assyrians, for heating water, and also in Persia during the later 16th century. And these records also proved that the first biogas digestion plant was built at a taper colony in Bombay, India in 1859. More researches on microbiology by scientists and microbiologists worldwide, proved successful, as they discovered the anaerobic bacteria and the condition that promotes methane gas production from waste.

The country with the greatest experience using large-scale digestion facilities has been Denmark, where 18 large centralized plants are now in operation. In many cases, these facilities co-digest manure, clean organic industrial wastes and source separated municipal solid waste (MSW).

The increasing emission of greenhouse gases, increasing water consumption and water pollution, declining soil fertility, unsatisfying waste management and the growing rate of deforestation must be seen as one of the unsustainable resource use system that prevail worldwide. Biogas technology is therefore, one of the important hardware components in chain of measure to counteract the above problems.

Why you need a Biogas?

The world’s climate is changing day by day, and we do nothing to stop the rate of increase, so Biogas is an important form of renewable energy which can be used where organic waste is produced in appropriate huge or small quantities.

Biogas is a low cost source of energy derived from renewable resources: animal dung, waste vegetables, rice leaves, sewage wastes, MSW, industrial wastes, farm wastes, human excretes and wastes etc.

You make use of low cost technology digester to provide biogas for your cooking and household activities, thereby cutting down your gas refill expenses.

It makes an important contribution to the protection and improvement of natural resources and environment.

It is a local way of obtaining methane (CH4) gas with low cost, which you can also start as a trade, producing and storing it in cylinders, and then distributing it to homes, or you can refine it more and distribute through gas pipe grids. Some individuals and companies are already doing this and selling it to you, but you don’t know about it.

It is an efficient sanitary system that enhances waste product disposals.

It can improve your economic welfare, if you decide to trade on it.

It has contributed to the global environment improvement by reducing fossil fuel usage, in some countries.

It will help minimize the habitation of insects, flies and mosquitoes within your environment, by utilizing your waste products to produce usable gas.

It will also save a lot of money for you, which you normally use for replacing your electric cookers and the refill of your cooking gas.

If you are a farmer or you own a garden, it will help refine some of your odoriferous effluents into odorless rich-fertilizer for your plants, trees, flowers and crops, hence, the constant use of chemical fertilizer will be reduced.

Now, How do you Design and Install the Biogas Digester to Produce a Biogas?

Firstly, before going ahead to think of producing a biogas, you must first reason. Some of the important things you must consider are:

Where can I site my digester?

You must make a wise choice here, especially if you want to use the biogas product for cooking in your home, therefore, you must make it closer to the house, but also near to your waste product source, which is the chief raw material you will use. This will help minimize long piping and installations.

What size of biogas digester do I want or need to meet my needs?

You must reason well here, considering the purpose of your desiring to own a biogas digester. Is it for family use (only cooking) or for a commercial purpose? And then how long do you want your biogas production from the digester to last? Good digesters last years.

Note; it is a general rule, the excreta produced by 10 fattening pigs will require a biogas digester of 4m3 liquid capacity (please make proper calculations for other wastes, this is the one I know, because I have used it many times). The standard diameter of polyethylene tubular film is 80, 125 and 200cm. For a number of animals, it is advisable to use a diameter of 80cm which gives a cross section area of 0.4*0.4p= 0.50m2.

On the average, 80% of the total volume in the tube corresponds to the liquid fraction, thus, to provide a liquid volume of 4m3 will require a biogasdigester with a length of; 10m. The recommendation dimension of the trench, which will hold a biodigester of the above dimension are; width at the top = 90cm, depth = 90cm, width at the bottom = 70cm, length = 10cm. Once you have decided on the size of the biodigester, the upper extremities of the trench should be defined using a rope attached to four posts.

Now you can dig the trench where you will install your digester. It is very important to observe the following rules: ensure that the side and floor is smooth with no protruding stones or roots, which would damage the plastic film (cellophane or nylon).

Ensure that the floor has slope of about 2.5% from the inlet to the exit (this would be 25cm for a biodigester of 10m length). Ensure that the soil is excavated and moved away from the edges of the trench so that movements around the biodigester during or after installation or subsequent heavy rains or maintenance do not cause soil to fall into the plastic film.

Materials required for constructing a Biogas Digester.

My recommended Biodigester length for a small family is 10 meter. To install a biogas plant of this size, the materials listed below are needed:

28 meters length of natural polyethylene plastic, 1000 gauges, 1.5 meters width.

8 used or new buckets (20 liters) of the same size or 2 cement pipes, 1-meter length, 12 inches in diameter.

1 PVC screw (the male adapter), 1 inch in diameter.

2 meters of transparent plastic hose of 11/4 inches in diameter.

1 PVC “T” 1 inch in diameter.

1 meter of pressure PVC pipe, 1 inch in diameter.

1 flat PVC cap, 1 inch in diameter.

2 round plastic or aluminum disks (20-15 centimeter in diameter with a central hole of 1 inch).

1 transparent plastic bottle- having an approximate capacity of 1 gallon.

An elastic rubber for tying and binding.

8 used plastic fertilizer sacks or its equivalent, depending on your country and location, any one you find is okay.

1 galvanized metallic pipe. ½ inch in diameter and 50cm in length.

1 tube of PVC glue.

An automobile or motorcycle as a source of exhaust.

1 plastic hose to take exhaust from the car to the place where the Biodigester will be installed.

Preparing the Plastic tube (polyethylene film):

Extend the 28m plastic bag on a flat floor that does not have any stones, sand or sharp objects to puncture or tear it. Therefore it is recommended to carry this operation out in a clean hall room. Then fold the film in two half folds and cut it into two parts, of about 14m each. Introduce the second nylon bag or polyethylene film into the first one by pulling it through the other, to ensure that is firm to withstand the contents to be introduced into it.

Materials required for the construction of the outlet valve and the order of assembling them:

The first step is to mark the place where the gas outlet valve will be placed. This should be 1.5m from the end of the plastic tube in the center of what will be the top of the biodigester. Order of assembling is as shown below:

Digging the Trench where the biodigester will be laid or planted;

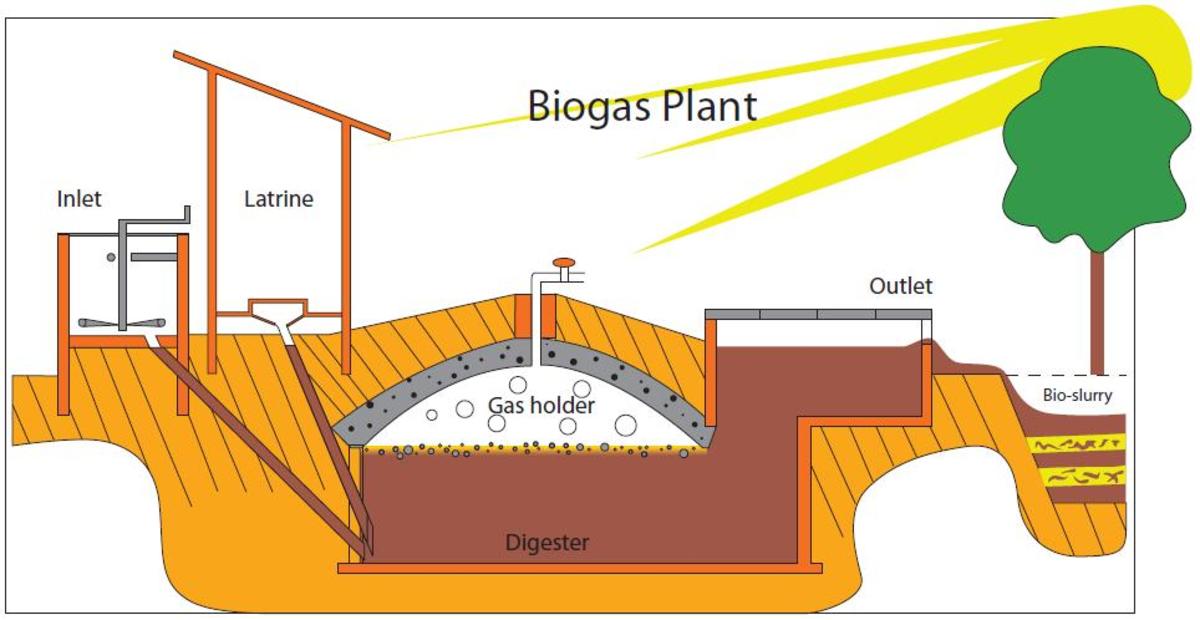

Once you have selected the appropriate location to install your biodigester, clear the site, and dig the ground (escavate the soil) to the required size and dimension. This trench is needed to make sure that your biodigester is protected from any damage and to help maintain appropriate atmospheric conditions for the production of biogas. See the drawing below for guidance on how to dig the trench.

Filling the biodigester with hot exhaust air and water:

If you have no better source of getting a hot exhaust air, please make use of either a vehicle or heavy engine exhaust waste, from the exhaust pipes. I normally make use of vehicle (van). Now, connect your exhaust hose to the hot air exhaust source and link it to one of the ends of the already prepared polyethylene film, then seal it. Then switch on your hot air source to introduce hot air into the bag (polyethylene film). Continue filling in hot air until the polyethylene bag is filled with hot exhaust air. Also start to introduce water through this same hose into the same bag, until it reaches the level of the ceramic tube or the inlet and outlet ends, and then you will observe that the hot air can no longer escape.

It will form something like a tubular balloon, and at this point, when the two opening valves (inlet and outlet) are opened, the hot exhaust air (now acting as gas) will not escape, it will be retained in the tube-like polyethylene film that is filled with hot air and water.

See the drawing below for more illustrations and guidance.

The construction and installation of the security valve:

The security valve is located at the middle of the tube-like polyethylene film (your biodigester), which is mounted on a stationary post. It is made up of a T-shaped joint, made from a PVC pipe of about 8-10cm in diameter. The T- joint is made by gluing together a straight pipe (PVC) with another pipe to form a T-joint. One of the ends is covered with a plastic cover that must be airtight, which will be later connected to wherever you want your biogas to be delivered kitchen, cylinder etc. And the other end is connected to the biodigester gas outlet opening that is located at the middle of the biodigester as shown in the drawing above. This is where biogas escapes when due, to the outside, and it is now captured using this security valve, for distribution and safety.

The remaining end of the security valve, which is the one pointing downwards (southward), is not inserted into a transparent plastic bottle, which should be either conical or tubular in shape. Together, the entire components of the security valve is tied stationary on a post, and small hole made at the neck of the plastic bottle, to maintain the required water level of the security valve. See drawing below for guidance.

Operation of the Biodigester:

Immediately after installations, a continuous source of waste excrement must be fed into the biodigester daily through one of its ends, which is the inlet. The excrement of waste should be blended very well, for instance, 18kg of fresh excrement requires 90kg of water for blending. Mix them thoroughly and then introduce into the biodigester through the inlet. The water is necessary to replace the water lost during the process of fermentation, and to keep a flowing material inside the biodigester, so as to ensure even fermentation of the wastes.

Now you should dig a hole next to the end of the biodigester outlet ends, to collect the effluent, which is very useful as organic fertilizer, for farming, gardening, feeding fish or growing flowers.

30 days after installation of the biodigester or biogas plant, you should now go and open the cover used to cover one of the ends of the security valve, connect this end to a burner for testing.

Testing and Result:

After the installation of the biodigester, a period of 26-30 days is given to allow for proper fermentation to take place. After which you should be able to test run your project, by opening the security valve, which I have earlier mentioned, you should be able to perceive a very choking smell, indicating the presence of methane gas. Now, put on your lighter and take it closer to the nozzle opening of the security valve. It should ignite and produce a bluish flame, to show full presence of methane gas.

If this occurs, your project is completed, but if it fails, please re-trace your steps, may be there is an error, I am sure it is a real and practical project, which I have been teaching people and also installing for others.

If you now wish to make this commercial, you must carry out more refinement of the gas, to reduce water content and some other impurities, to make it distributable and as well marketable. The one I explained here is for private or family use. And if it is properly maintained and installed, it should last up to a period of 3 years.

Approximate cost:

It all depends on your country location and economy, as regards to the cost of buying all the required materials listed here. For my country, taking dollar conversion rate as to my country’s money:

If $1=#140

It means that this project should cost you around $170 dollars, if you install it yourself.