Affordable Hydrogen Economy - Iridium and Platinum Replacement

Future Energy via Hydrogen

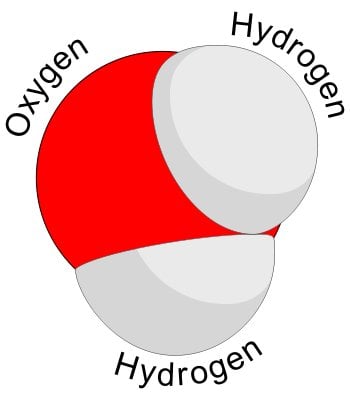

When all is said and done hydrogen still seems the best alternative fuel to replace petro-fuels. The reasons are numerous. Hydrogen burns in a much broader ranges of densities in earth-normal atmosphere; from a mere 4% to 75%. This is a much much broader range than any other hydrocarbon.

Hydrogen is plentiful, even though there is no truly (elemental) hydrogen in the atmosphere. However, since it is a chief component of water it is virtually everywhere on the planet.

Hydrogen, when burned, produces nothing but water and very slight residual pollutants that are already found in the atmosphere. These residual pollutants (notably nitrous oxide) is produced when hydrogen is burned in earth-normal atmosphere.

Three Main Problems

There are three problems with using hydrogen as fuel. They are:

- The energy required to release hydrogen from water via electrolysis

- The materials (expense) required for electrolysis; noble metals are expensive and rare

- The storage of the evolved (scientific term for generation) of hydrogen.

This hub discusses solutions to the second of these problems.

Replacing Iridium Oxide and Platinum in Electrolysis of Water

Splitting Water with Electricity

Electrolysis is the splitting of water into it's component elements hydrogen and oxygen. Typically, this process is done electrically with oxygen forming from the cathode (negative electrode) and hydrogen from the anode (positive electrode). In this process two very rare and noble metals have historically been used as electrodes (anodes and cathodes). These two metals are iridium oxide and platinum.

You may not know that iridium is a rare metal and therefore expensive; you most certainly know that platinum is an expensive metal.

Both these metals, when used to create hydrogen and oxygen from water; corrode. And corroded electrodes must be replaced for electrolysis to continue. Thus electrolysis of water gets to be somewhat expensive just in electrode materials.

On top of that the water that is used must be distilled (additional processing in other words) and have trace minerals (salts) added to it to get the best reaction.

With the special "noble" metals and the processing to make the water ideal, electrolysis of water is not the most economical way to produce hydrogen and oxygen.

Dan Nocera

Dan Nocera is the Dreyfus Professor of Energy at the Massachusetts Institute of Technology. He is also the director of Solar Revolutions Project. The Nocera Group is tasked with studying energy conversion in chemistry and biology. To put this another way The Group studies the conversion of energy in chemical reactions and in leafy green plants.

Nocera and his group have been able to replace the Iridium Oxide anode with a Cobalt Phosphate anode. The Group has also found that the Platinum electrode can be replaced by a Nickel Borate composite. The great thing about these materials is that they are much cheaper to produce and are composed of materials that are much more abundant than the aforementioned iridium and platinum. Both these composite materials are also considerably cheaper to produce than refined Iridium Oxide and Platinum.

This will make electrode replacement, a considerable cost factor in electrolysis of water, considerably cheaper since each of the replacement materials is at least one tenth the cost to produce than the two noble metal electrodes.

Interesting Side Effects

One of the problems with the original platinum electrode was it's tendency to corrode. The Nocera group determined that any material used in the electrolysis of water would corrode so in the process of finding noble metal replacements they also determined that they should find a way to lessen or mitigate corrosion.

Self Repairing Electrode

What the group found is that they could create the Nickel Borate electrode naturally ablates (sheds material) as it is used in the electrolysis process. By creating a precise blend of Nickel Borate they found that the material, while in solution, tended to migrate back to the electrode and redeposit on it. In short the Nickel Borate electrode heals itself, much like the tungsten filament in a halogen-tungsten light-bulb.

Plain Water Electrolysis

Another problem with noble metal electrolysis was the preparation of the water. Using the noble metals as catalysts meant that the water had to be distilled and seeded with minute amounts of minerals for the electroysis to work effectively. it also had to be in a narrow temperature range to be most conducive to electrolysis.

With the Nickel Borate electrode replacement, plain water, right out of the tap, can be used rather than a specially prepared lab quality control of purified water seeded with trace elements. Better still the new catalysts work with salt-water.

Reduced Energy Usage

Finally, another effect of these new materials is that less voltage and current are required to split the water molecules. In fact a reduction of 33% of the energy required has been reported.

Summary

The Nocera Group has successfully replaced noble metal electrodes with more common and readily available materials. These materials are no only more abundant on earth, making them far easier to replace, they are also much less expensive.

In the process of replacing the electrode materials with cheaper alternatives they have also found a way to use ordinary water rather than a distilled and seeded source. In fact the two materials mentioned above allow for the electrolysis of any water...including tap and sea-water.

Original Material

| Cost per Ounce

| Replacement

| Cost per Ounce

| Cost Differential

|

|---|---|---|---|---|

Iridium Oxide

| $860 (estimated)

| Cobalt Phosphate

| $11.00 (estimated)

| 1.28%

|

Platinum

| $1,700 (estimated)

| Nickel Borate

| $0.54 (estimated)

| 0.03%

|

Disclaimer

The author owns no stock in any company developing electrolysis equipment nor does the author personally know any of the scientists participating in this research.

Though the author stands to make a small profit from any advertising associated with this article, and the article itself, the author has no control over the advertising or its content.