CPV systems – solar, not cost per view

Concentrating Technology

When I was looking for hubs about concentrating photovoltaic (CPV), most of the search results were about the Cost Per View topic, so this hub is NOT about optimizing traffic.

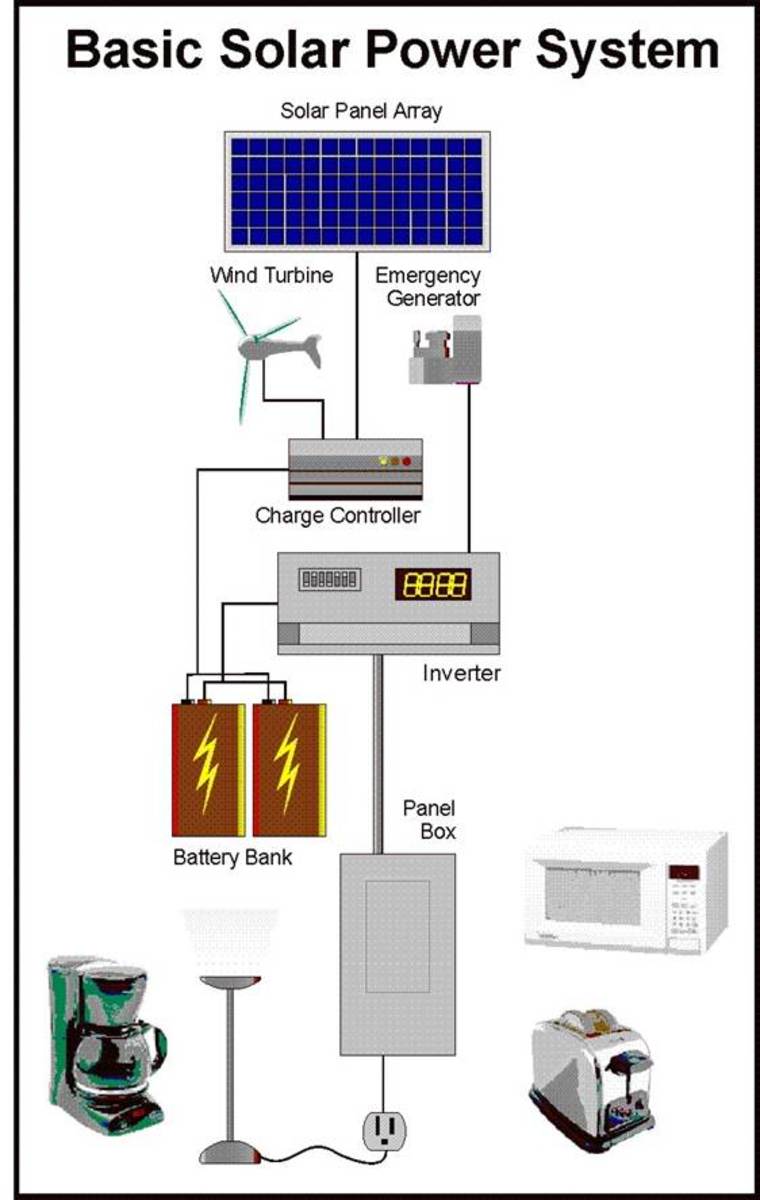

It is about a rather new development that originates from space applications, CPV technology, in particular high CPV (HCPV). The idea is to concentrate the sun via optical technology (mirrors or lenses) onto a small area of high efficiency PV cells. As only the direct sunlight (direct normal irradiation) can be utilized, HCPV design require dual axis tracking. The size of a cell is smaller than a conventional silicon cell, the concentration ratio (measure of concentration, called concentration ratio or multiple of a sun) can be more than 1000 suns. If the ratio is lower than about 100, it is called low concentration ratio and usually utilizes silicon cells.

Since the development of multi-junction cells in the late 1980s, conversion efficiency has been constantly increasing and is currently well above 40%. Multi-junction cells work by stacking two or three cells made of different semiconductor materials on top of one another, where each cell responses to a specific portion of the solar spectrum.

Cell developers in the 40+ range

The highest efficiency of 43.5% at > 400 suns was so far reached in 2011 by Solar Junction, a young start-up company; their cells are production ready. Not far behind is Spire Semiconductor, who developed a commercially available triple-junction cell with a record 42.3 % at 400 suns in 2010 in collaboration with National Renewable Energy Laboratory (NREL).

There are several manufacturers in the 40% range. Boeing-Spectrolab, Inc. set a record 41.6% and is offering their C4MJ cell with 40% typical efficiency. Since 2007 Azur Space Solar Power GmbH in Germany produces triple-junction concentrator solar cells, with an efficiency of 40% at 500 suns, developed in cooperation with the Fraunhofer Institute for Solar Energy (ISE). JDSU, an optical communications company, just recently joined the CPV market and produces multi-junction cells with a performance of 40%. Canada based Cyrium’s Technologies Inc. announced their QDEC cell with an efficiency of ca. 40% at >500 concentration ratio in 2009.

CPV system developers

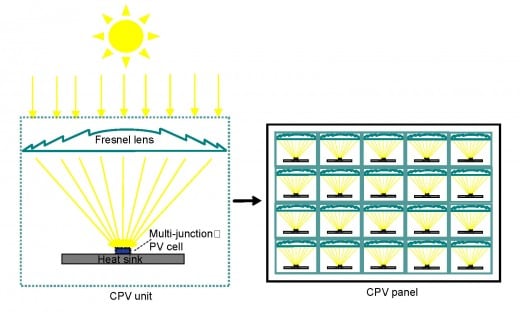

The most common design for HCPV plants consists of modules mounted on a pole, with a panel of Fresnel lenses (flat lenses using a saw tooth design to focus the incoming light) concentrating the sunlight onto a multi-junction PV cell.

Like manufacturer Amonix, CA, whose modules have a concentration ratio of about 500 and a system efficiency of 29%. Their modules can be found in North Americas currently largest 5 MW CPV plant in Hatch, New Mexico. They have several plants operating in the Southwestern US, like a 2 MW plant at the Solar Zone at the University of Arizona, which started operation in 2011. The 30 MW Alamosa Solar Generating Project in Colorado will also implement Amonix HCPV modules. It received a loan guarantee from the Department of Energy in 2011 and will be developed by Cogentrix Energy.

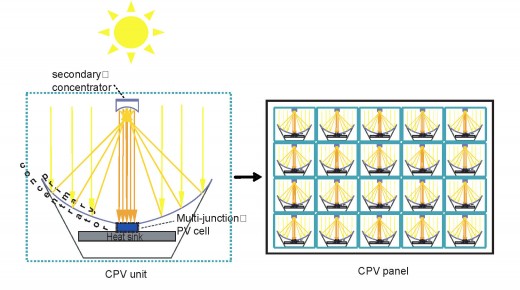

Another leader in developing CPV systems is SolFocus. Their system is similar, with a concentrating optics consisting of a primary and secondary mirror and a ratio of 650. They completed a couple of 1 MW solar farms in CA and Arizona, like one on the campus of Victor Valley College in Victorville and one on Nichols farm in Hanford, and one at Arizona Western College in Yuma. An 8.5 MW in Portugal is in construction phase, and a 1.28 MW on Crete, Greece and more than 20 in the kW range are operating worldwide. Their biggest project yet was announced earlier this year, a 450 MW project in Baja California, Mexico. They will join forces with developer Synergy Technologies, et. al., and plan to begin construction of the first 50 MW later in 2012.

Manufacturer Soitec’s (located in Grenoble, France) largest project is a 1.37 MW in Questa, New Mexico, which was installed in 2009. They implement Concentrix Technology for their optics, which was originally being developed by the Fraunhofer Institute for Solar Energy. Their concentration ratio is 500 with modules similar to Solfocus and Amonix designs. OPEL Solar developed their Mk-I HCPV panel, with a dual refractive concentrator technology, focusing sunlight on Spectrolabs triple-junction cells. Emcore is reaching 1090 suns by using lenses and mirrors in their G3-1090X module.

Semprius is rather new solar company located in North Carolina, who has developed a proprietary printing process to fabricate the smallest PV cells with 33.9% efficiency. Their module has a ratio of 1100 suns and beginning of production is planned for summer 2012.

There are a number of HCPV installations in all parts of the world, where direct solar irradiation is high enough – US, Europe (especially Mediterranean region), Asia (Taiwan, China), and even Australia, where solar power projects are rather otherwise scarce. More are planned as system efficiencies continue to increase and design issues (lens condensation, heat dissipation) are being worked on.