Combining Solar Technologies –CPV/T Systems

Both, concentrating photovoltaic (CPV) as well as solar thermal systems have a great potential to deliver clean, renewable energy in a cost-effective way. Many projects as well as studies focusing on either one of the two technologies as standalone system have been conducted over the past several years. Only a handful of combined CPV and solar thermal systems (CPV/T) were realized so far. In particular I would like to talk about hybrid parabolic trough – solar thermal designs.

CPV Systems

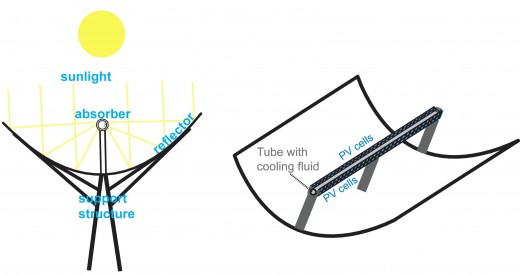

As opposed to the rather large-area conventional flat-plate photovoltaic panels, CPV systems focus sunlight onto a rather small PV cell. In order to accomplish this in an efficient way an adequate tracking mechanism is required (preferably 2 axis tracking for high concentration, stand alone CPV systems). Parabolic troughs have a low ratio below 100 and require only one axis tracking; they are aligned North-South and follow the suns path from East to West during the course of the day. This is also sufficient for low concentration of about 10 to 40 suns used in low concentration PV/T systems discussed here. Furthermore, optical components need to concentrate the sunlight from a large panel area to a smaller area consisting of photovoltaic cells. They can be based on reflective (mirrors) or refractive (lenses) optic technology, both of which are relatively inexpensive and highly developed. Finally, a lot of research has been done the past couple of years to increase the efficiency of PV cells, which are the center piece. The amount of photovoltaic material needed for CPV can be much smaller than for conventional flat-plate PV, thereby potentially reducing costs.

CPV/T Designs

In a combined parabolic concentrator PV design, the conventional fluid filled absorber tube, which runs along the focal line of the parabolic trough, is basically “surrounded” by PV cells. Only a couple of projects implement a hybrid version of solar thermal parabolic troughs and concentrating PV. One of the main challenge in solar concentrating systems is that the heat portion of the solar spectrum is also focused onto the focal line, thus on the PV cells. Unfortunately, efficiency of the cells decreases with temperature, so they have to be cooled with a heat sink (like Aluminum profile known as ‘cooling fins’). Another way of cooling the solar cells is using water. This leads to the possibility of the combined production of electricity and heat.

CPV/T Systems

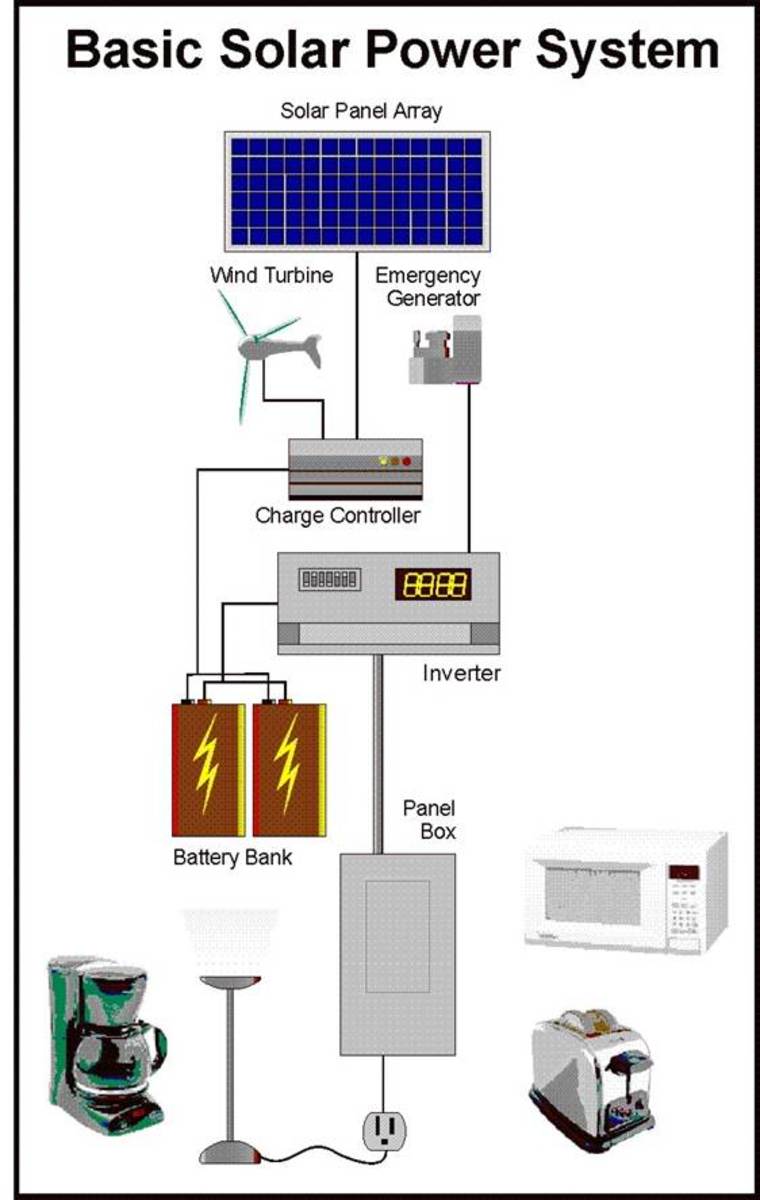

The ‘Centre for Sustainable Energy Systems’, at Australian National University, built a system in a federally funded cooperation with the industry. They developed a Combined Heat and Power Solar (‘CHAPS’) concentrator system, which combines hot water and electricity generation into a single unit. It is based on one axis tracking glass mirrors that reflect light at about 30 times concentration ratio onto a receiver lined with solar cells. The in the course of this project developed ‘Sliver’ cells (single crystal silicon) are cooled with water flowing in a channel at the back. They installed a 40kW roof mounted prototype at Bruce Hall, Canberra, in 2004. It provides an estimated 60% of electricity consumption and between one and two thirds of the hot water consumption.

Commercially available CPV/T designs were developed by the Swedish company Absolicon Solar Concentrator, former Arontis. Their first power plant began operation in 2011 and produces 100 kWth thermal heat and 20 kWel electricity. The Absolicon X10 PVT features an output temperature of 75 deg C, with low concentration ratio and single axis tracking. Menova Engineering in Fresno, CA, developed the Power-Spar Concentrated Solar systems. They utilize multi junction PV cells, with the option of one or two axis tracking method. In their liquid cooling method, they use a heat transfer fluid to transfer the heat to several applications (domestic, process heat, thermal storage,…). Up to this date, very little other CPV/T systems are commercially available and heat dissipation (heat transfer from the cells to the cooling fluid) remains an issue.