Common Problems of Ball-Screws & Corrective Measures

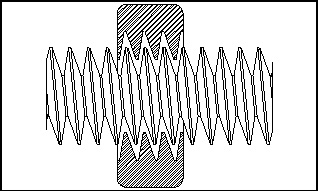

What are Ball Screws?

Backlash

If you are noticing an undesirable amount of backlash in the ball screw, it is possible that the balls and the nut’s thread radius have started wearing out. This happens due to following factors:

- Incorrect or no lubrication

- Contamination Absence of counterbalance (over vertical axis machine)

- Misalignment

- More workload on the machine than the ball screw’s capability

- Abuse, damage, tampering or assembling of ball screw with extra preload

- Extensive use

Corrective measures – To correct this problem, abrasive lapping should be done. In more severe cases, regrinding of the threading radius should be done. So also, the worn out balls can be replaced with high grade, oversized chrome steel ones. If the machine is not positioned properly and the ball screw assembly is seen to undergoing backlash, ball screw should be removed and rebuilt, before getting worn out beyond repair.

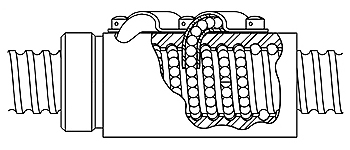

Locking Up or Skidding

Ball nuts have a re-circulating system which lets the balls return back by moving internally or externally as per the design. If this system is severely damaged, it makes the ball nut hold up on the screw. Sometimes, the system is slightly impaired because of which balls just stop circulating. However, this damages the screw, as the balls skid in the ball troughs, instead of rolling. This failure of the return system takes place because of:

- A harmful clash on the machine axis

- A forklift or some other weighty object bumping on the machine table

- Abuse, damage or tampering of the ball screw

- Extensive use

Corrective measure – Reconditioning or repair of the ball screw assembly should be done at once in this case. If there is still a forcible rotation of the ball screw or nut, permanent damage to the return system can occur and the ball screw may require more elaborate repair or replacement.

Since their introduction in the late 1930s, ball screws are gaining increasing importance continuously, and from their original application in machine tools, they are now being increasingly used in LCDs, semiconductors and robots too. This is because of their supremacy over rest of linear motion-transmitting components, regarding the balance between price and performance and the ease with which they can be used and controlled. Here we will see some common problems encountered by ball screws and how to solve them.

When the Ball Nut Is Mistakenly Run Off the End of the Screw

This happens at times during servicing of the machine tools. Sometimes the balls fall out of the assembly. In this case:

- You should not try to rotate the nut back to the screw

- You should gather as many balls and other parts as you can, which come out of the nut

Corrective measures – Take out the ball screw of the machine. If you don’t have exact knowledge of working of the return system, your attempt to reassemble the ball nut may cause permanent damage. If the screw has slight or no wear or damage, a good quality ball screw servicing shop can re-ball it for much less cost than that of a full rebuilding or a new assembly.