DC Machines

Machine is one of the device which can be used to convert the one form of energy to another form

The device which converts from the mechanical energy into electrical energy is known as generator.

The device which converts from the electrical energy into mechanical energy is known as motor.

DC machines

These machines which runs under the dc power then the machines is known as DC machines.

There are two types they are:

- DC generator

- DC motor

DC generator:

The generator is the device which converts the mechanical energy into electrical energy, the mechanical energy which is obtain from the either motor, turbine or other devices.

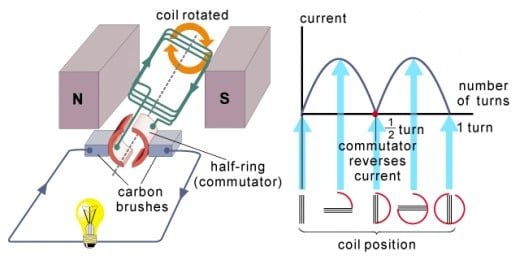

The principal of DC generator:

The generator works on the principle of Faradays law of electromagnetic induction i.e whenever a rotating conductor placed in the magnetic field then the conductor cuts the magnetic field then the conductor dynamically emf induced in it.

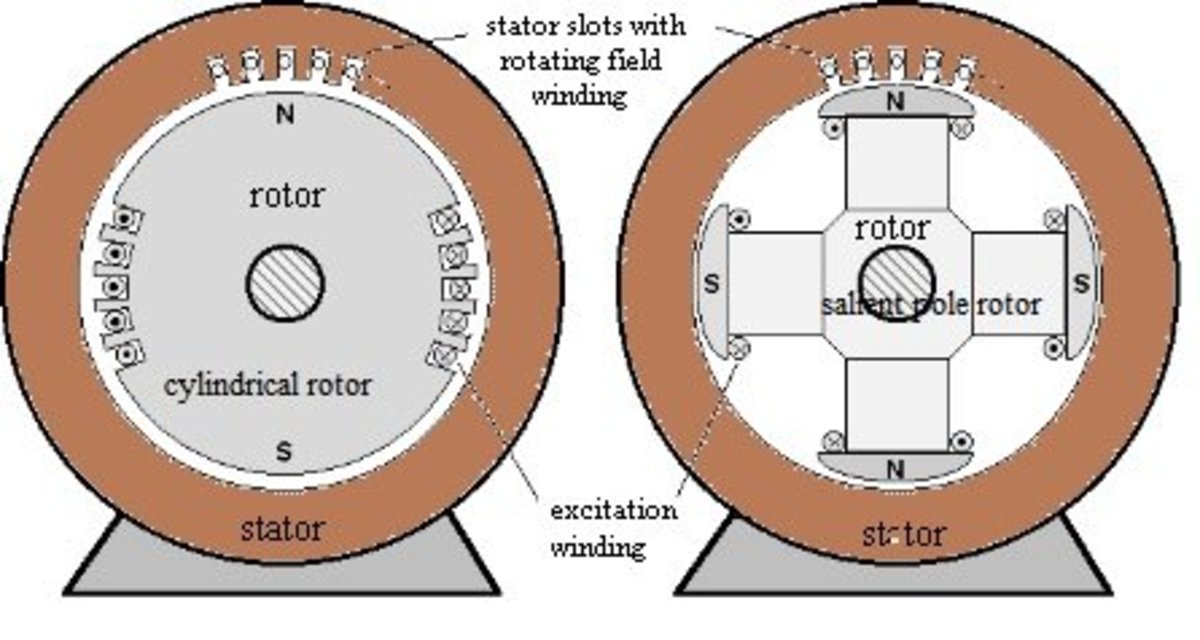

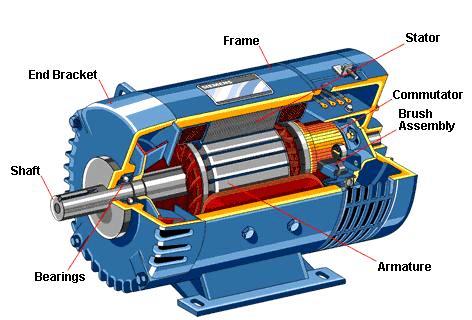

Construction of DC Machine:

The main components are to require built the DC Machine.

They are:

Rotor side:

- Armature

- Shaft

- Commutator

Stator side:

- Yoke

- Pole shoe and pole core

- Field Winding

- Inter poles

- Brush and brush holders

Yoke:

It is outer most cover of the dc machine. It protects the inner parts of the machine and it is made up of low reluctance material like cast iron, silicon steel etc..it has to carry the magnetic flux i.e. to provide the closed path for the flux.

Pole shoe and pole core:

In generally the pole core is the solid material and the pole shoe the laminated one in small machine for reducing the eddy current losses. In modern days the both pole shoe and pole core is made up of annealed steel. The purpose of the pole core is to provide the flux and to support the field winding.

Inter poles:

These poles are smaller size when compare to main poles and also placed between the main poles the purpose the poles to reduce the armature reaction.

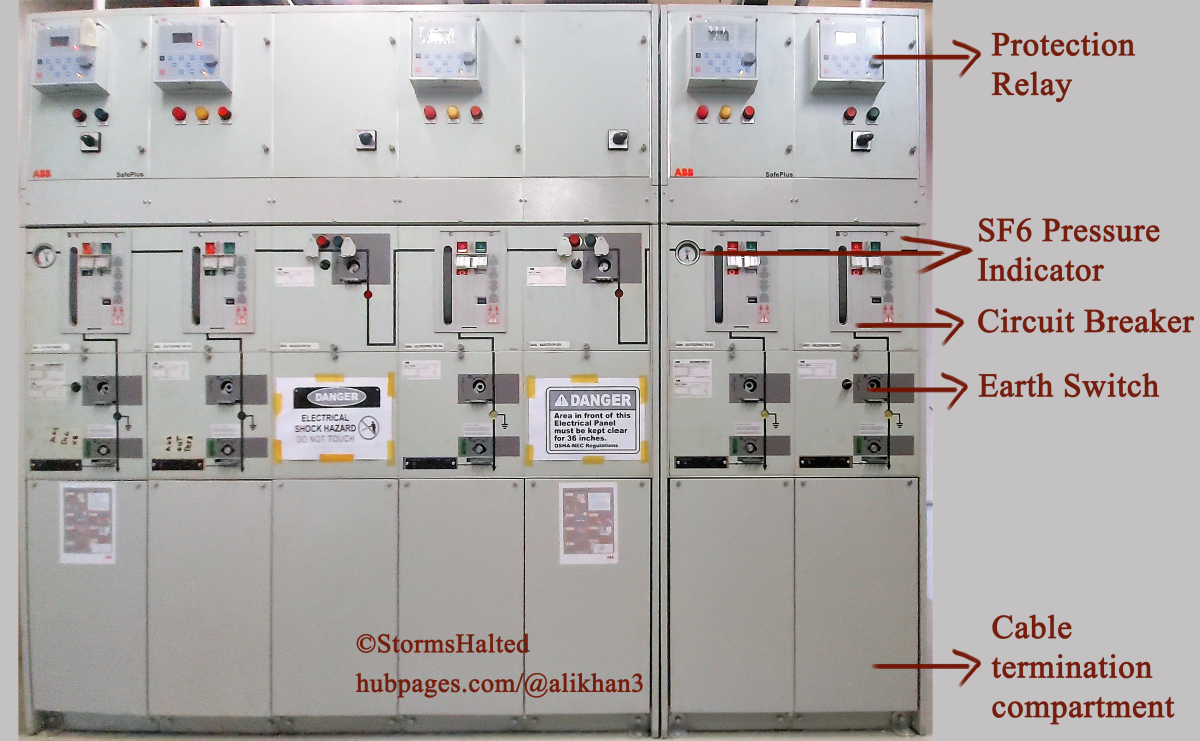

Brushes:

It is the device which used to collect the current from the commutator and it deliver to load most of the brushes used materials is carbon, graphite etc..

Armature:

It is rotating device in machine it is mounted on the shaft and is made up of lamination to reduce the eddy current losses. And is made up of material is cast iron and is consisting of armature winding either lap or wave winding.

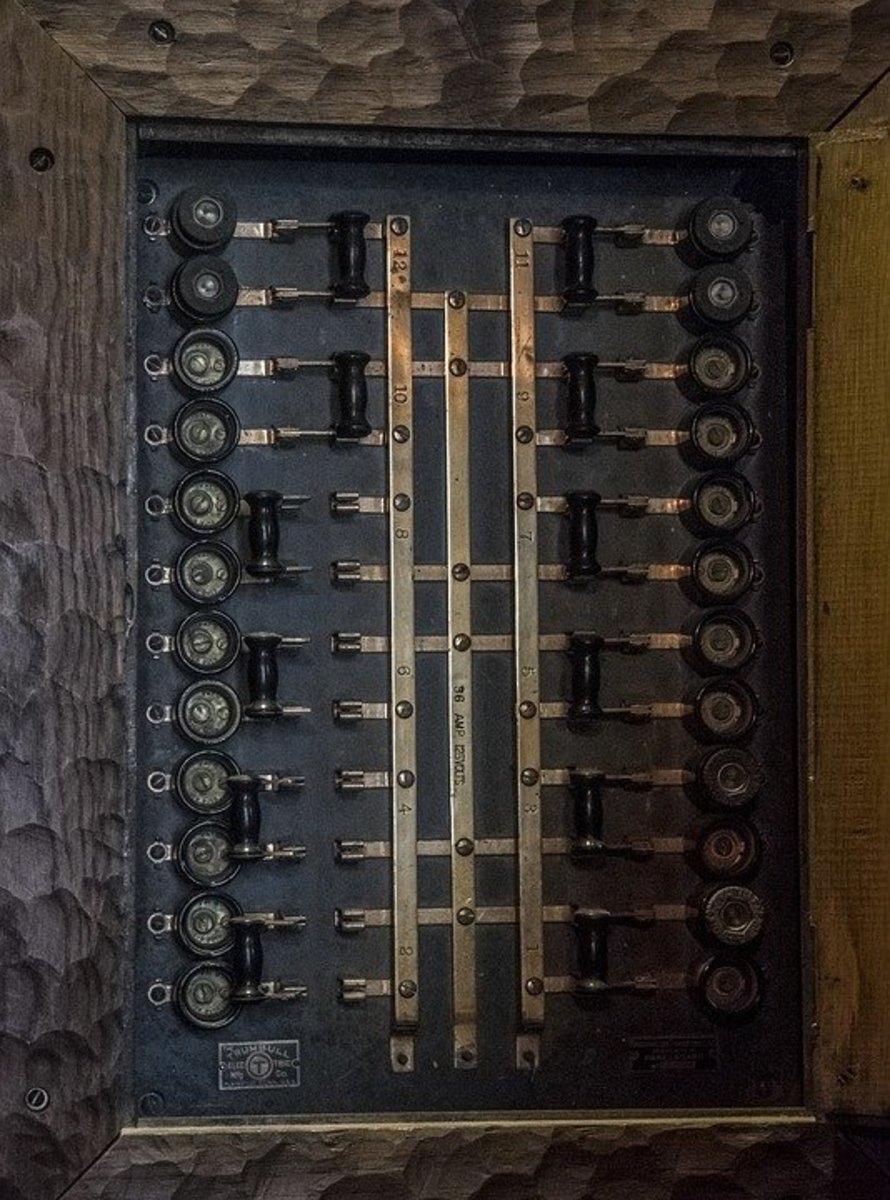

Commutator:

It is also called as the mechanical rectifier in generator and an inverter in motor. The commutator connections is always depend on the type armature winding.these are generally made up of hard coppers and the brushes are placed on it to collect the current.

Types of DC Generators:

There are two types, they are:

Based on the field excitation

- Separately excited dc generator

- Self excited dc generator

i. DC shunt generator

ii. DC series generator

iii. DC compound generator

- Dc long shunt compound generator

- Dc short shunt compound generator

Separately excited dc generator:

In this type of generators the separate dc source is used to excite the field winding of the generator and the armature supplies to the load

Self excited dc generator:

In this type of generator there is no need of any external dc source to excite the field winding but in these generators the field is excited by the current produced by the generator it self

DC shunt generator:

The field winding of the generator is connected across (parallel) the armature this type of generator is known as shunt generator

DC series generator:

The field winding of the generator is connected series with the armature this type of generator is known as series generator

DC compound generator:

This type of the generator is the combination of series generator and shunt generator

There are two types they are:

- Dc long shunt compound generator

- Dc short shunt compound generator

DC Motor:

DC motor is the device which is used to convert the electrical energy in to mechanical energy.

Principle of DC motor:

The motor works on the principle of the fardays law of electromagnetic induction i.e. whenever the current carrying conductor placed in the magnetic field then the conductor cuts the magnetic field and developed force in it. Because of the current carrying element.

The construction of the DC motor is similar to the DC generator.

Types of DC motor:

Based on the field excitation

- Separately excited DC motor

- Self excited DC motor

i. DC shunt motor

ii. DC series motor

iii. DC compound motor

- DC long shunt compound motor

- DC short shunt compound motor

Speed control methods for shunt motor:

- Flux control method

- Armature control method

Speed control methods for series motor:

Armature control method:

- Armature resistance control

- Shunted armature control

- Armature terminal voltage control

Flux control method:

- Field diverter

- Armature diverter

- Tapping field control

- Paralleling field coils

Losses in the DC machine(motor/generator):

There are three types of losses.

they are:

- Iron losses (core losses)

- Hysteresis losses

- Eddy current losses

- Mechanical losses (constant losses)

- Friction losses

- Windage losses

- Variable losses

- Armature copper losses

- Field copper losses

© 2015 KALYAN CHAKRAVARTHY THADAKA