Fabric Bleaching.

Fabric Inspecting & Bleaching.

Bleaching.

The woven cloth from weaving which is around four meters per kg is out from the weaving machine after it is woven to its full length from the beam that is feeding the machine,the length of this is around 500 meters normally.However it varies depending on the type of fabric.Very long lengths are avoided since they may get spoiled by dirt,dust or any stains and even if the quality of the yarn is not according to specification.The yarn undergoes heavy stresses and strain during weaving and if the yarn is having poor strength or if the sizing is badly done.On account of these factors and any other factors long lengths are avoided.

Once the fabric is taken out from the looms it goes to gray ware house where every meter of cloth is inspected for all physical and chemical dirt's as also any damage to the cloth in any place.If there are any protruding threads the same is removed at the root.Very small damages are skill fully removed by repair.If there are damages in many places its flaged with a colored thread at the end with a sewing thread so that its visible when rolled in to long lengths.The number of such colored threads in the roll can be counted and there will be washable markings of date of weaving and time of weaving as also the weaving machine number.This is normally done to all weaving machines to pin point the workman who makes any damages.

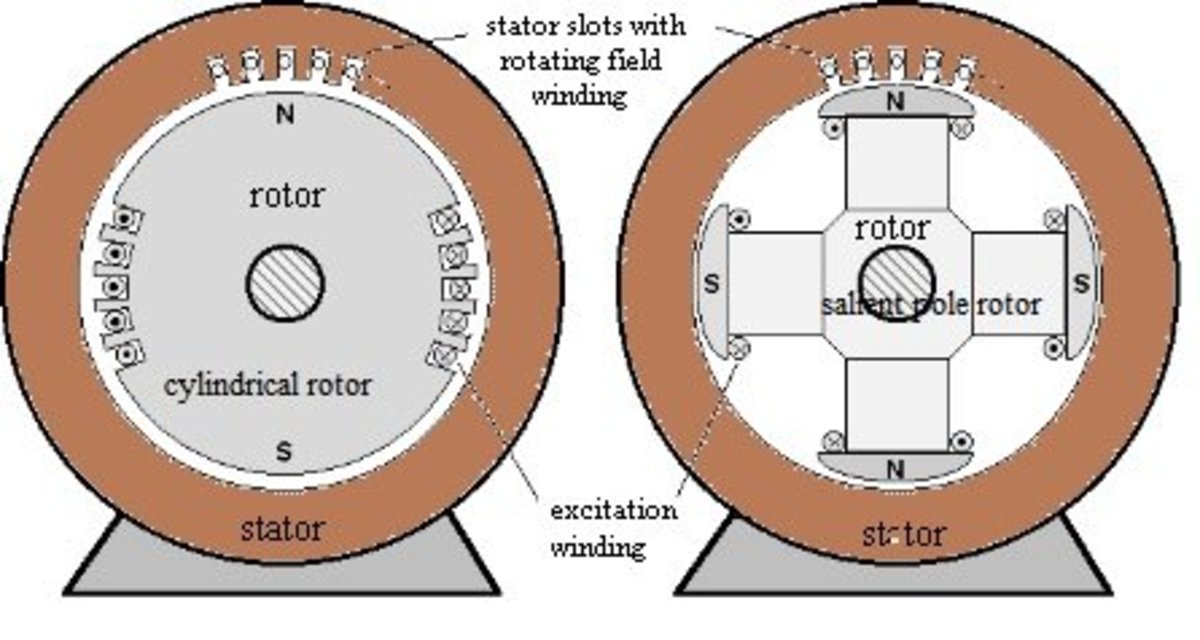

After the cloth is inspected and graded it is sent for Scouring and Bleaching process.The cloth is scoured and Bleached for removing all physical and chemical impurities with the use of Computerized Bleaching Machine which bleaches the fabric as required either for full bleaching or half/semi bleaching.These are called closed Jiggers which takes around 3000 meters of cloth and completes the bleaching in 18 to 20 hours.The scouring and bleaching liquids are prepared and kept in separate tanks and they get fed to the jiggers automatically once the start button is pressed.The computer controlled machine does the job with out further need for any care.

There is a separate process before bleaching called singing to remove any fibers that protrude on the surface of the cloth.This gives the cloth a fine fully white cloth.This process is done on a machine where the surface is cleaned of any fibers by a series of gas flames over which the cloth goes at speeds that do not burn the cloth.

Once this singing,scouring and bleaching is done the cloth is again checked over the inspecting machines and folded or rolled as needed and markings are stamped with details that are required.