Implementation of route distribution & navigation system

How to make the employee's job easier while facilitating productivity.

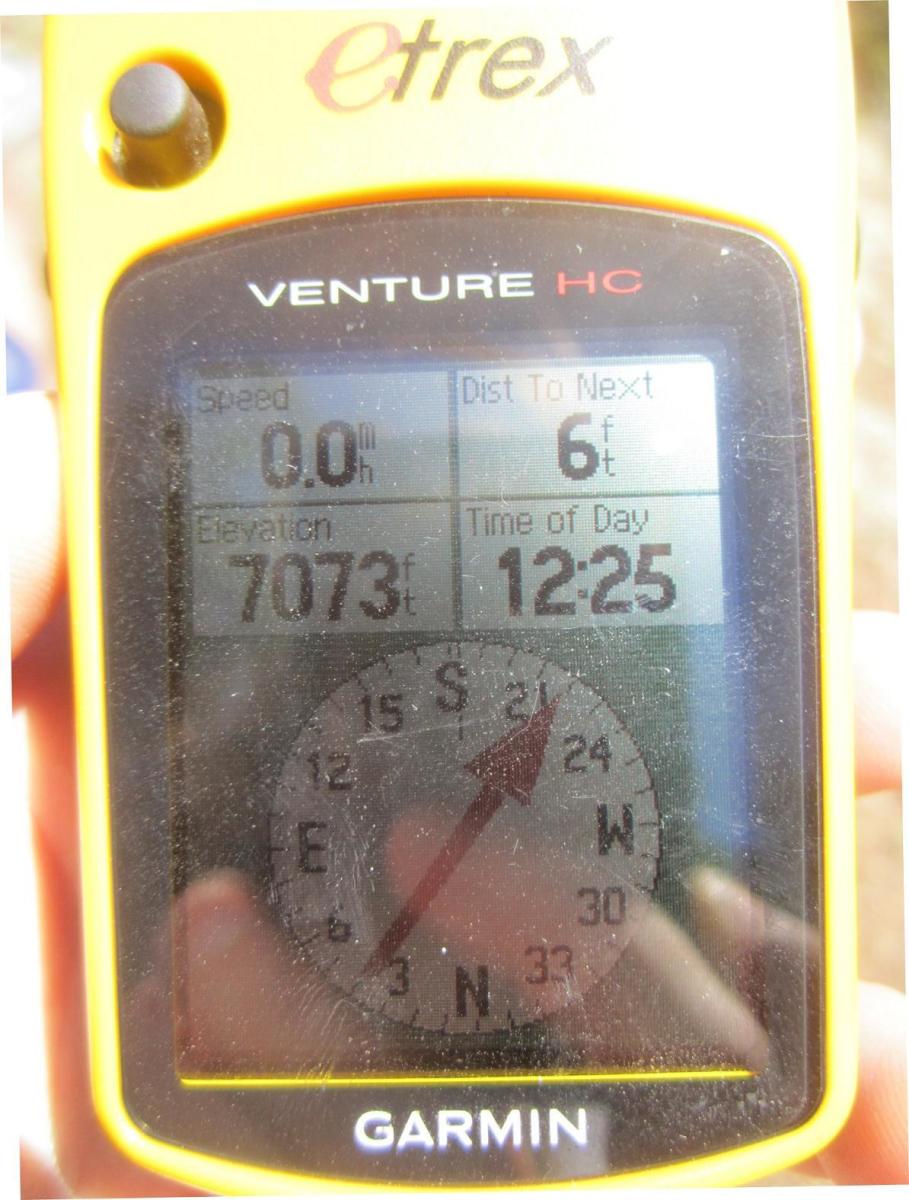

Global Positioning System (GPS) is a very useful tool;

most of us who have it in our vehicle know the significance of its use. It helps us navigate the geographic world of our

cornerstone. It tells us which road leads to which direction, and which direction is the quickest path from which

point.

Therefore, it is no surprise why companies that utilize commercial vehicles to

render services to their customers find it to be a dependable tool. Employers may want to use it as a tool

to monitor the location of their asset in a timely fashion. This technology is

a great tool, and it can help management understand how they can improve on

productivity through proper routing.

Since the GPS technology is able to track the path of every employee’s truck in

real time, then it also knows how much time the employee spends on every job. This is a good piece of information

to have, because if the employer can tell how long it takes the employee to do each job,

then the employer should also be able to tell why one job takes longer than the

other. The time spent on each job would have been associated with condition

codes which would correspond with time. And since every job is never exactly identical,

would have made it almost impossible to set a determinant on how many jobs are

achievable on a daily basis.

However, through careful observation, the employer can predict the quantity of

jobs that are possible on a daily basis, even when given some particular

circumstances. This will be accomplished by taking an average of total completed jobs that is possible under the worst case scenario,

and that average may be use as a base mark.

This can be viewed

as a good configuration for production base when the company provides services

that do not involved safety. For those companies where safety is their main

priority, their production margin may be set below their base mark regardless

of the circumstances at hand. It would allow their employees more time on each

job so that they can be relax, and leave a job only when they are assured that

the job they left is safe and secured.

Since employees skills are directly related to their productivity, than the

amount of jobs that is achievable from the experience employee is not to be

compared with the least experience one. Therefore when the margin is captured,

it should reflect the total work load of the least experience employee.

Inexperience in this sense implies an employee who has never done this particular

job before, not to be confused with one who has had similar experiences in a different field. This

sample of employee’s capability would allow the employer to take a more accurate production base

that is possible under the worst case scenario. And this production base would be use as a margin to

monitor productivity curves.

Now, as management, if we are so concern about productivity, then it is in our

interest that we make the employee’s job easier so that we get the production

we desire. We can ask ourselves this question. How can we modify the GPS system

that is now installed in the MDSI terminals to make the employee's jobs easier?

After all, the easier it is for the employees to do their jobs, the more

production is possible.

Well, in order to know how to modify the MDSI terminals to correspond with the

GPS within the network, we need to know what we’re modifying it for. As a

mechanic, we are given a run; this run may consist of ten - fifteen jobs at

different locations. We do as much as we can as long as we do our job safe.

However, during the traveling time we are not concerned with job safety until

we get to our destination. At this point the only safety we care about is our

driving. And it is within that time frame that we'll facilitate productivity.

What that means exactly is that we'll equip the employees with a navigation

system that would provide them with the quickest route to their destinations.

And we will do this by modifying our database to correlate with our GPS System.

They say don’t waste time, because time is of the essence, time is precious and

time is money, so let us make our time worth every penny. In order to foresee how we can modify the MDSI

terminals to maximize production, the manager must have walked the mechanic

shoe, because more often than that it is the employees who knows what has to be

improved so that their jobs can become much easier.

As a mechanic, the problem we face at times is the fact that we do not always

know how the run is scattered across our geographic map. Very often we go from point X to A

bypassing K & L without knowing that we could have done K & L before reaching A, if the appointments

are in the same time frame, then it would save some time to hit K & L

before getting to A. But since we don’t always know how the work is distributed

across the map, we don’t have the luxury to do them in the best preferred

order.

To solve this problem, we can take advantage of the GPS system; modify it so

that we link it with our run which connects with the database via a wireless network. We can do this by

mapping each run with the GPS system. And another word, when the employees upload their work onto the

MDSI terminals, they will have the option to view their work displayed on the

map of that unit. Which mean they would be able to visually note which jobs are

closest to each other, and between what time slots they belong in?

This is a very important piece of information to the mechanics, because with it

they don’t have to keep looking at a map or invest in a navigation system to see where they headed. If

the global positioning system can track them, it should also help them. And it will help them by

providing them with a clear path to their next job.

To make it even easier, we can assign colors to the run schedule displayed on

the unit map. The AM jobs can be coded with a blue dot, PM jobs with a black dot, and PSI appointments

with a red dot and so on. This will enable the employees to quickly glance at the navigation map, and know

right upfront which jobs carry the most urgency, and what time slot does it

belong to. Whichever one that job is, the employee would tap on it and the

direction would open up, showing the employee the quickest commercial path available

to get to that job.

It is important to note, if the employees do not have to guess which job they should

hit next, then we have made their job easier. And since it has become easier

for them to get from point A to B, less time is wasted traveling. We can call this a bottom up strategy, because to know the

possibilities, you the manager must have walked in the same shoe as the employee.

Now that we have seen how production can be improved, let us now concentrate on

how all this can be possible. We are now entering the territory of our IT department. To link the

GPS system with our database, we might have to use some SQL statements or whatever the database

languages that the company uses.

Whether it's XML, SQL, XP ath or Database Access - the idea is the same. Since

it’s been awhile since I’ve written any, I’m a little rusted. Nonetheless, here is an example

demonstrating how it can be possible. This example is not exactly correct, but

it's there to help us visualize the possibilities …. Select unit_id, job_id

from address where job_id = employee_id. Then insert into employee_id (3, '53',

2'48', '93', 3 '50', 2, '80' ).

The big task however, is how do you link this information to the navigation

system? This is where the IT department comes in, because to make this idea work that's exactly what has to

happen, otherwise we are back to square one. Since we already have the GPS

installed, we should find a way to make good use of it. Its purpose should not

just be to track our employees, but also to facilitate productivity by making

route distribution fun to maneuver through.

This is only a suggestion from a mechanic's point of view, if this idea were to

pass on to any IT

department, I’m certain it would be possible. Perhaps a software program may

have to be developed for this idea to come true.

They are no null

ideas, an idea may be missing a few elements, but that doesn't mean it carries

no value. However, regardless of what the case may be, if this idea were to

come true, many companies across the nation would have benefited from it.

Well, I recently found out that this idea is not new, and that someone patented part of the functionality that may be use in accordance with this idea. It was patented March 11, 2003. This patent is estimated to be expired March 5, 2021. The claim for this patent is

“a navigation system for providing data from servers to a navigation terminal via a network “To view the

description of this patent, please click here.

I first submitted this idea to one http://www.robtex.com/dns/us.ngrid.com.html an incoming mail for National Grid. Than when I did not hear any response, I posted it as a blog on hubpages on 11/04/2009. After months of being asked by Davison ideas wanted to submit my ideas I submitted it.

I spoke to their staff Sean E. Slane and after explaining to him what the idea was he suggested that I take it down from hubpages which I had recently did - but now it's back. Now that Davison is asking for money in advance to do research for preexisting patent I felt as though this couldn't be right.

I believe if an idea is good and it is none existent I wouldn't be ask for money and secondly that idea could be pass on to someone else that I've never met before. Today I no longer work for National Grid somethings are questionable and I'm in the process of finding what there are.