Tips Ladder Do's and Don'ts-Maintenance- Cruz

Defying gravity is one of those things that man just can't get enough of; airplanes, bungee jumps, and pole vaulting to name a few. What power it is to easily extend your capabilities these days with the tools at our disposal like high lifts, boom trucks, and even ladders. With a quick setup and a short climb you suddenly become ten feet tall or more. It's not a new invention as man has piled rocks from the early days of man to reach just a little higher, but we sure have taken it a long way from there.

Ladders, for me, are a love-hate relationship at best. Love the service they provide and hate the queasy feeling you get when it shifts suddenly and you feel like it will tip. Love the lightweight designs these days but still hate lugging them around. Love the electrically safe ladders but hate working on electrical while on a ladder. This is one of those things I just do because it has to be done but, would rather work out of a platform lift than off of a ladder. I particularly hate extension ladders and I don't think I'm alone in that. Probably sounds like I am afraid of heights but I am not, I am afraid of being unstable at heights.

I think most of my sentiments are shared by most and we use ladders because we have to. The thing is that, if you must use a ladder don't you want to use one in perfect condition? I know I do. Poor ladders, they get treated really badly from my experience. I see contractors tossing them around and maintenance techs who fold them then let them fall to the ground before picking them up. Of course the guy who cracked the ladder won't be the guy to use it next, it will be me.

Serious?

I make a serious point to the techs about tool respect in general and always spout the adage " take care of your tools and they will take care of you". I wholeheartedly believe that adage and have seen both sides of the coin. The hammer the tech threw the other day that now has a broken claw just slipped its grip and he landed on his back, really should have taken care of his tool.

When it comes to ladders I preach a sermon because I do not want them mistreated and I really won't stand for it. You should not stand for it either weather,,you are the leader of maintenance or a tech, the abuse of the equipment effects everyone's safety. When I have a particular technician who treats the equipment with little or no respect I assume he has no respect and it is time to have a talk. I will give him the same basics that are in this article and evaluate over time if it has sunk in, if yes great, if no then I will be replacing one tech.Most techs get it and understand why I am so adamant about the treatment of equipment and especially ladders.

Most departments have a ladder inspection procedure in place and if they do not, they need to get one. Most places inspect ladders once a month and require the techs to do an inspection before each use. This is like anything else and can get blown out of proportion where there needs be three signatures before you can use a ladder, don't laugh because I have personally seen it.

It's kind of hard to see things from a company's perspective and a lot of the time we do not have all the information but, if it was your company to what lengths would you go, to prevent injuries and lawsuits. The company already has three recordable accidents due to ladders and twenty near misses, none of this you know about, they really need to take some action. This company would not have a choice but to take action or risk opening themselves to lawsuits. The best part of this is that in the staff and corporate meetings its not all insurance and suits from my experience, its genuine concern for safety.

Just Check It Out

I have seen some good, fair, and poor ladder programs before, I will put forward here some the things I thought were really good in those programs. I would say that the very first thing to be done is a ladder inspection and safety class for the personnel authorized to use ladders, most places already do this. I think it is important to convey that you as the manager will not accept unsafe behaviors, usage, or poor treatment of the equipment, you have to draw a line in the sand. This preliminary training is to teach the user how to inspect on the spot before use, this is where the accidents are really saved. Every safety inspection and protocol will help to prevent accidents but they all pale in comparison to a through inspection right before use.

Numbering all ladders in the facility is important for record keeping but a inspection sticker on the ladder with the initials and date of the last inspection is more important. The monthly ladder inspection is an absolute must in my opinion as anything could have happened to these ladders and someone needs to catch and lock the damaged equipment out. The most important reason for this is that everyone feels they can use a ladder and will, when they need it and that includes non-authorized persons. Unless you keep your ladders locked up anyone can use it and if the ladder fails they will sue and they will win whether they were authorized or not. The idea is that this equipment must always be in perfect working order or it must be repaired or disposed of.

I spoke before of a three signature process for using a ladder. There really is nothing wrong with this idea except that it eats up a lot of time and seems counter productive and overly redundant. I see some wisdom in its concept as the ladder will surely get inspected with three techs there, kind of a checks and balance system. I would hope that not all three techs would pencil whip the inspection form but it could happen. I don't personally prescribe to this method and would opt for a very thorough monthly inspection with pre-use inspection stressed to the techs.

Secured

Now the we have a good and inspected ladder we need to put it to good use. This is where I really find the most errors and the biggest opportunity for injuries. A lot of people really don't use ladders safely at all and I have seen some really scary situations. My favorite was the factory next door, where they had a man basket attached to a forklift on uneven terrain with a 12 foot ladder in the basket and the forklift at full extension with a tech on the top rung reaching out to a building louver in the wind, I'm not kidding.

Our safety guy crossed the street and offered the use of a tech and our boom lift, they were all for it. I think they got it or maybe not, they were one stiff gust or sway of the lift truck from a fatality, not good. I have stopped techs who set ladders up on soft ground, a real recipe for a fall. My second favorite was, the stairmaster I call it, when a tech built up a platform out of loose 2x4s to level a ladder on a staircase, this was nuts. Proper positioning of ladder and the do's and don'ts are normally addressed in training and OSHA has specific guidelines on ladder use and positioning. Most ladder use is common sense but knowing and understanding proper positioning is very important.

Another approach I have seen is where ladders were hung on a wall and a locking mechanism was used to prevent unauthorized use, this also made it very easy to lock out a damaged ladders. I would recommend this approach for control and loss prevention as well, had many ladders disappear after some contractors had been through.

Tying off extension ladders is a must in my view as they are so unstable. The standard procedure I have used is the buddy system. When a tech needed to use an extension ladder he must set it up with another tech, but never alone. He would extend the ladder and position it according to the trained procedure. The bottom of the ladder is to be secured or tied off to a stable object so that the ladder is held into the structure that it is resting on. The top of the ladder must be a minimum of three rungs over and beyond the top of the structure level. The tech will ascend the ladder while the other tech holds the ladder for stability. When the tech reaches the top he is to secure the top of the ladder so it can not slide to either side. The tech at the bottom must remain while the ladder is in use and reverse the steps when finished. This seems like a lot of wasted manpower and time but the damn things are dangerous and I would rather not have use one at all.

You Just Have To Believe

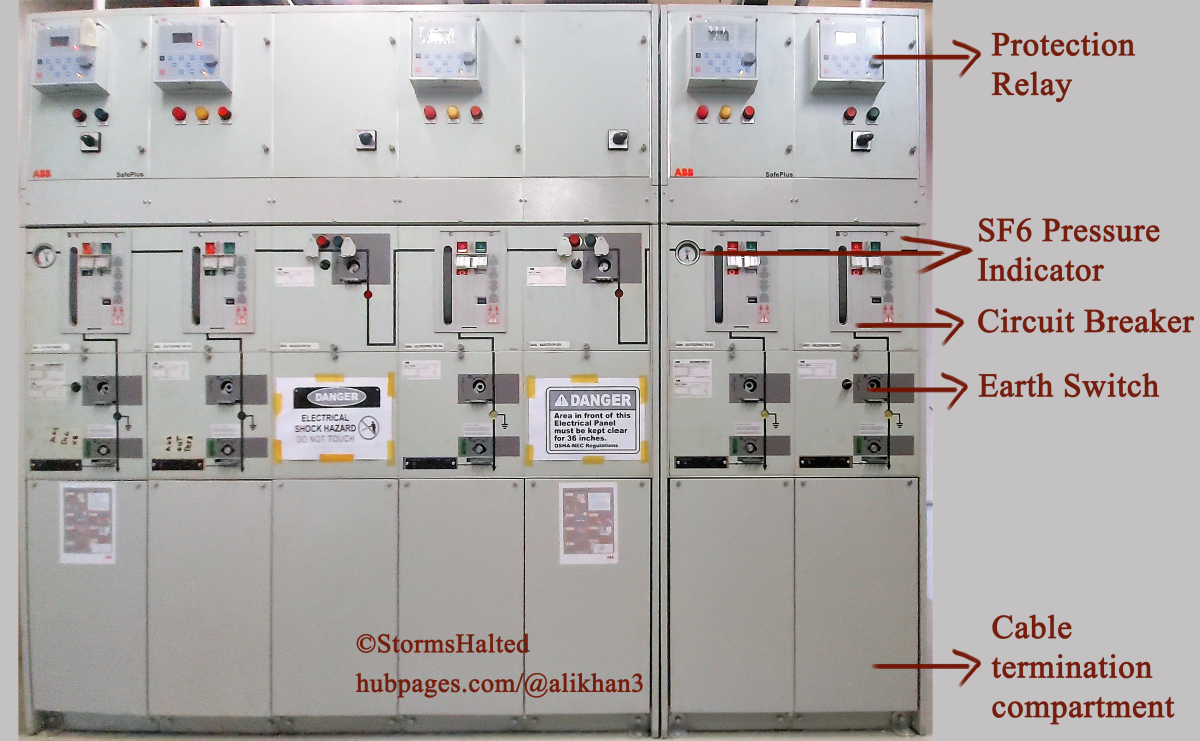

Types of ladders are getting diverse with new designs and better materials coming out. Most of us know that aluminum ladders are really dangerous around electricity, especially in the winter when people are hanging lights on their house in the snow. Oops, one light isn't working I will just go up there and jiggle it a little, pow! man down. Fiberglass ladders or some other listed electrically safe ladder must be used when working around electricity. The factory will spend the extra money for the fiberglass ladder but the average home owner won't due to the large price difference.

In the end it is up to the training, the individual, and the manager to make ladder safety happen. The technician is the one who should be insisting on safety and it is the manager's job to get him to think this way. Any time you elevate yourself off the ground you are at risk especially when you realize just how little it takes to kill or severely injure yourself. Falling from four feet can kill you just as easily as a fall from twenty. Unfortunately in factory environments you have a greater chance of falling onto something or into something not to mention unforgiving concrete floors.

The last item I want to touch on is situational awareness. Yes, you know you are on a ladder just on the other side of the door, but does everyone else? More ladder falls happen for this reason then you would think. Someone flings that door open and down you come. The best practice I have seen used signs, cones, barricades, and locks. This is a no brainer, wherever you set up a ladder you must restrict access and direct traffic, its that simple. On the other side of a door is a leading culprit and should be stressed how important it is to block and notify. It does not take very long to toss a couple of cones out there and write a warning note to stick on the door, but most guys don't do it. Always notify everyone around as to what you are doing, that goes for just about anything else you're working on. You can eliminate a lot of nasty surprises by letting people know where you are going to be and what you will be doing, just a wise thing to do.

It is like another adage "you can lead a horse to water but you can't make him drink", the people using the equipment have to want safety. If there are people in your department that aren't on board with this kind of safety mentality then you should evaluate if they really need to be there. I know it sounds harsh, but it is true and even your golden boy may have to hit the road if he doesn't take safety seriously.

I absolutely do not want you to take my word on any of this, look up OSHA's most recent recommendations on ladders. I have pasted a link below for a book about ladder safety and litigation, this could be a real eye opener and a good training tool..