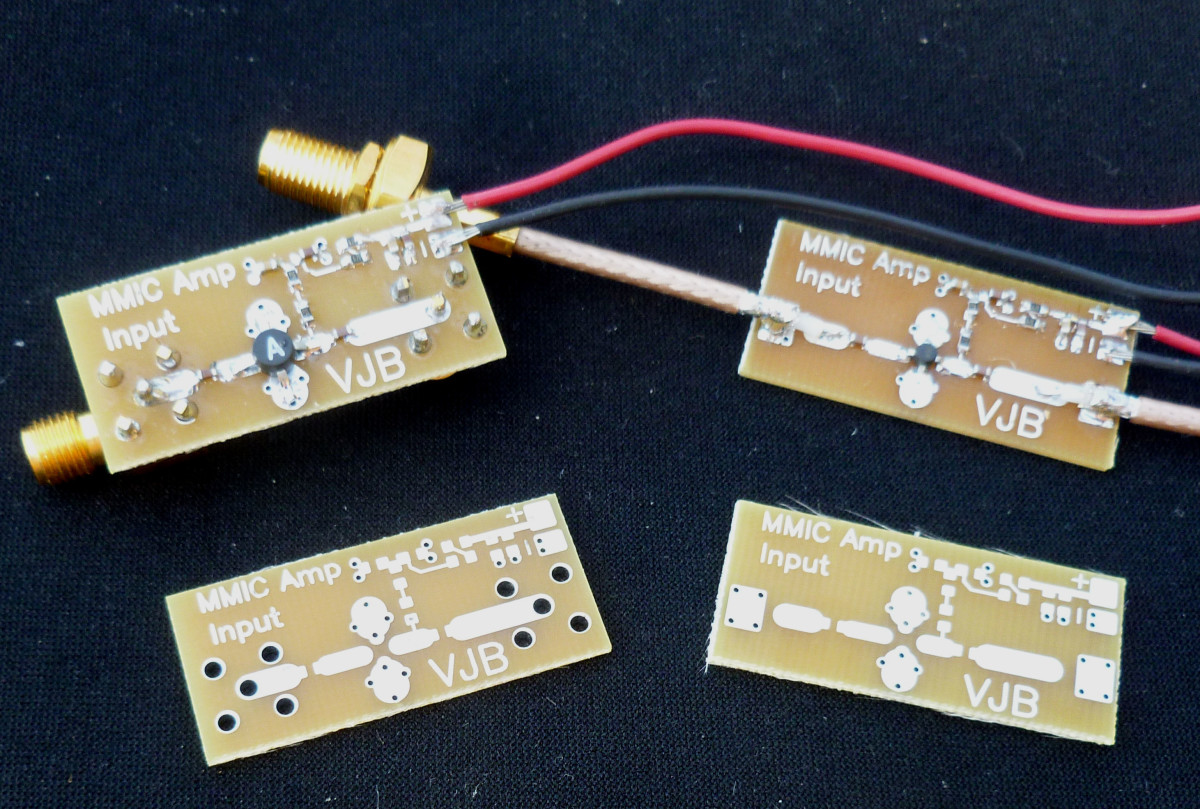

Paper and Glue SMD Circuit Construction

Paper and Glue SMD Circuit Construction

There are a number of reasons to construct a circuit with SMD components minus a PCB. The time required to design and make a PCB will require several hours minimum, an unappealing proposition. Also PCB’s for SMD components are mostly empty space so it is possible to construct more compact circuits without them. This is useful for making test equipment such as active oscilloscope probes or for miniature transmitters.

How To

There are a number of possible ways to breadboard with SMD components. One possibility is to use double sided sticky tape. The results depend very much on the brand of the tape. With some brands the SMD components start slipping around like they are on ice skating ring when you try to solder them. Other brands give somewhat better results.

By far the most reliable method I have found to do PCB-less SMD construction is a simple paper and glue technique.

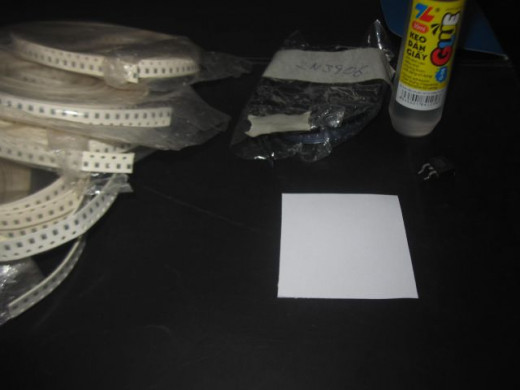

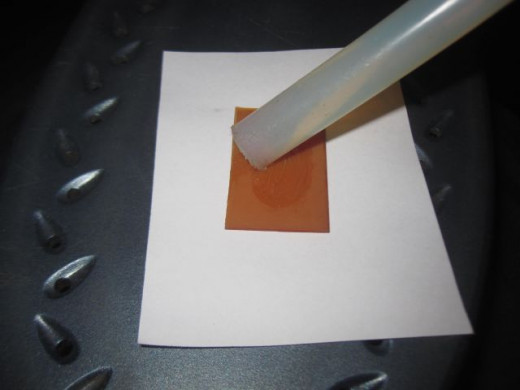

Cut out a square of paper and spread a layer of cheap water soluble paper glue over it. If the circuit has a lot of components use a thick layer of glue to prevent it drying out too soon.

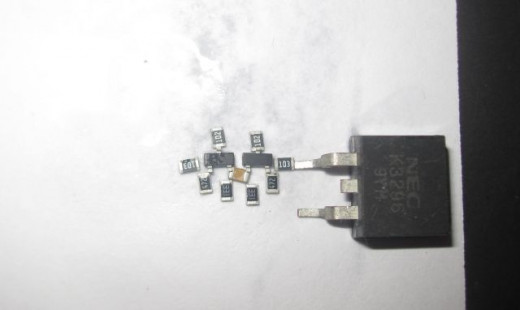

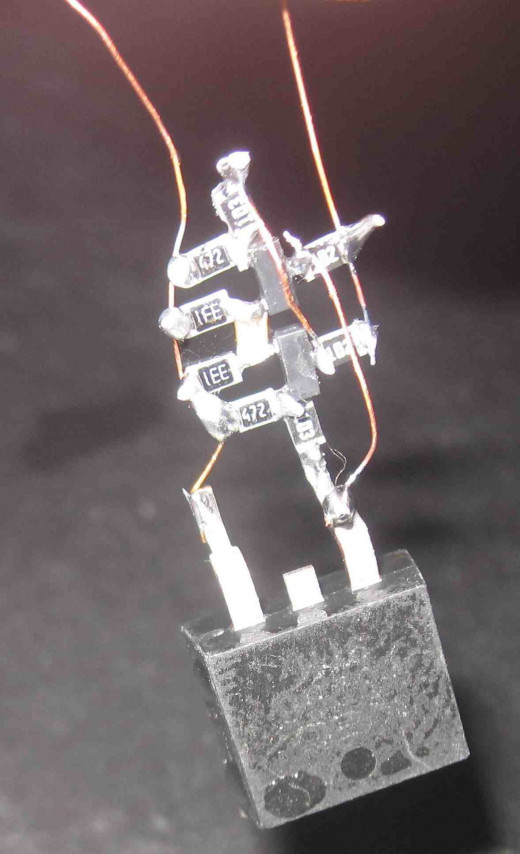

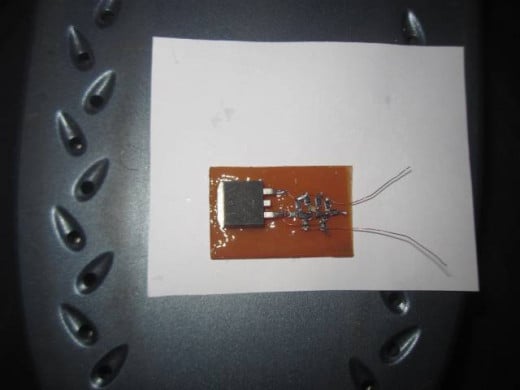

Place the components on the paper with the ends of the components you wish to solder together touching each other. I usually stick SMD transistors upside-down to facilitate soldering.

Let the paper dry completely. You can use a hair dryer if you wish.

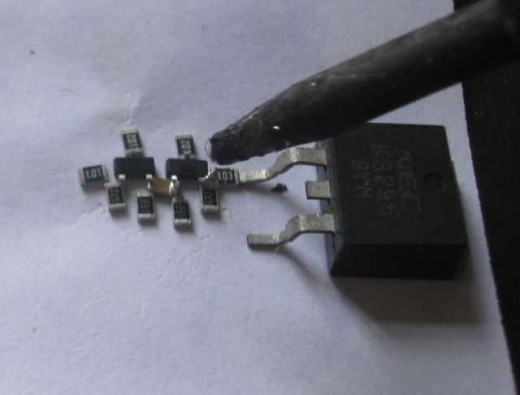

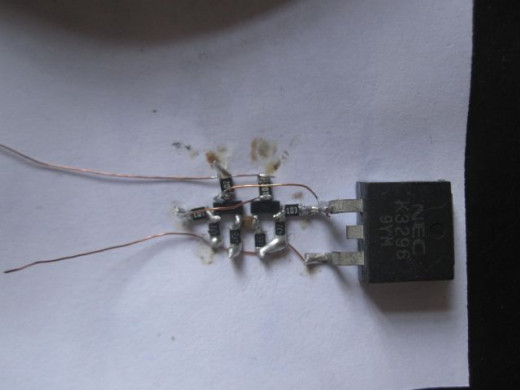

Next solder up the components. You will find that the components are firmly stuck to the paper and have no tendency to move around even with heat applied.

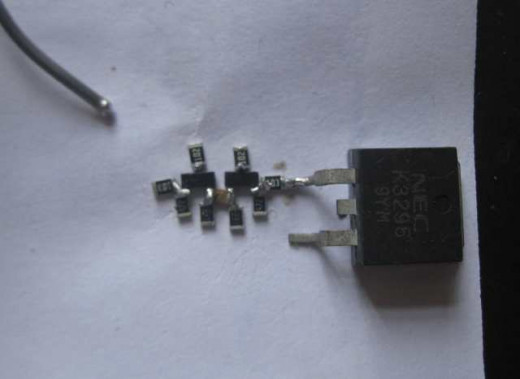

Use strands of copper taken from ordinary multi-stranded copper wire to wire up the SMD components. It is normal to end up a 3D wiring arrangement in space.

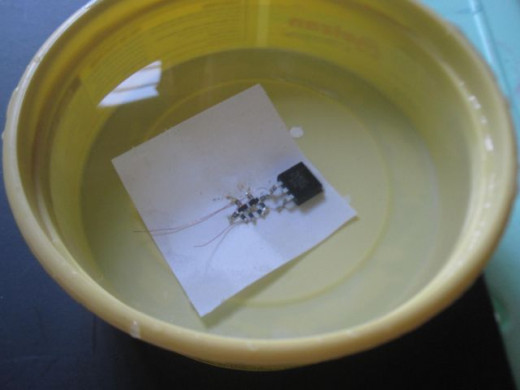

Place the circuit in water and soak off the paper. Leave the circuit in water long enough to make sure all the paper glue has washed away.

After the circuit has dried it needs to be attached to a rigid surface. You can use super-glue or hot melt glue. You may wish to completely pot the circuit in glue if there are uninsulated copper wires crossing near each other.

Figure 1

Figure 2

Figure 3

Figure 4

Figure 5

Figure 6

Figure 7

Figure 8

Figure 9

Conclusion

This is a really simple and quick way of constructing SMD circuits. There are some limitations to this technique though often you can break down a large circuit into a number of smaller circuits and proceed that way. Also it could be tricky to apply with SMD integrated circuits. Nevertheless it is a useful construction technique in many common circumstances.