Parabolic trough systems and their potential – it’s all about hybrid

Reliable Power Generation

Concentrating solar power (CSP) plants are the oldest type of solar power plant and are widely considered a proven technology. Even though they still have to overcome a variety of difficulties, there are some benefits that should be pointed out.

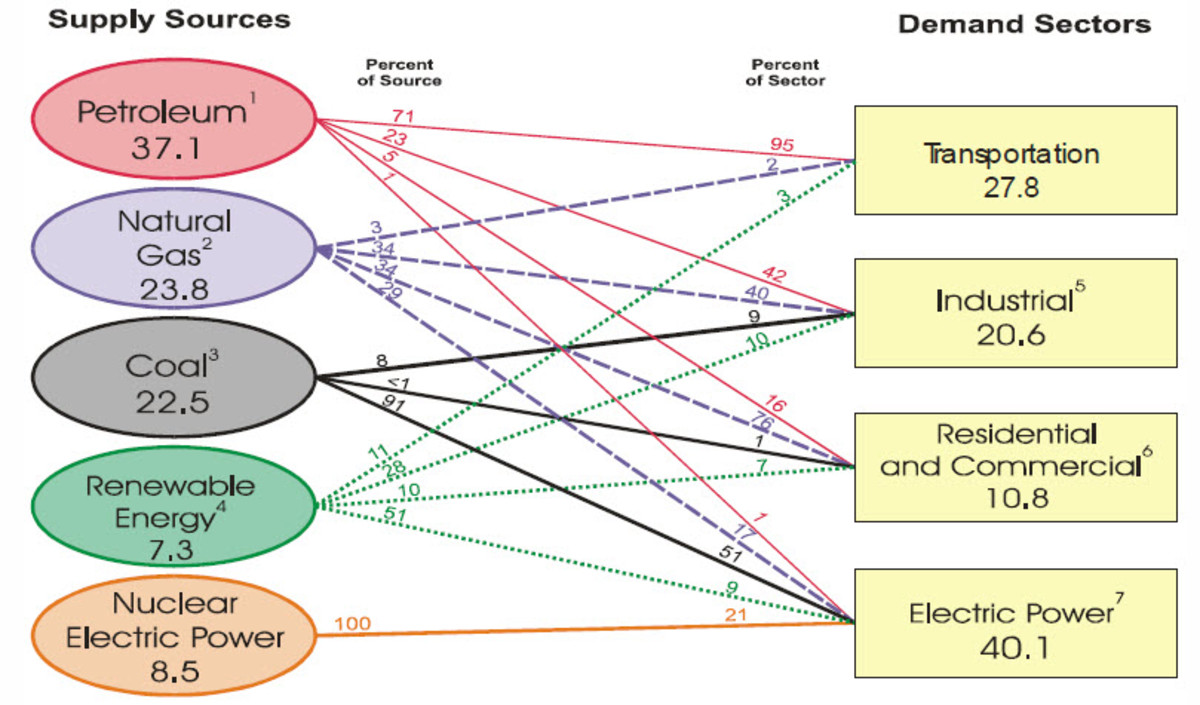

One major advantage is that they can provide a consistent power output. This is not only a result of their capability to store thermal energy by using storage tanks, but also due to their combinability with conventional combined cycle fossil fuel (usually natural gas) power plants. In a combined cycle power plant the hot exhaust gas of the gas turbine is (re)used for producing steam for the steam turbine, considerably increasing plant efficiency. In an Integrated Solar Combined Cycle (ISCC) the heat produced by the solar field is providing an additional heat source enhancing steam production for the steam turbine, resulting in a higher output.

Such combination of solar energy and natural gas in a hybrid plant allows for uninterrupted power generation with natural gas being an inexpensive and abundant fuel and convenient back up source. Integration in an existing fossil fuel power plant gives furthermore the advantage of an already built infrastructure (grid connection, turbines, overall site set up).

Mostly Natural Gas

In Morocco (Ain Beni Mathar), Abener developed a 470 MW hybrid plant with 20 MW originating from parabolic troughs and 450 MW from natural gas. It was commissioned in 2010 and started operation in 2011. Another integrated solar combined cycle power plant got connected to the grid in 2012 in Algeria (Hassi R'mel). It was developed by New Energy Algeria and Abengoa and generates 20 MW through parabolic troughs, combined with 130 MW produced by natural gas. The Shams 1 plant in the United Arab Emirates (southwest of Abu Dhabi), is a 100 MW plant under construction and planned to be operational in 2012. It is being built by Masdar Powder, and only 18% of electricity is going to come from natural gas. In Kuraymat, Egypt, Iberdrola Engineering was contracted to build a hybrid natural gas and solar thermal power plant with a capacity of 150 MW. It was completed in December 2010 and the solar thermal part contributes 40 MW to the total capacity. Iran built an integrated solar combined cycle plant in Yazd. It has a capacity of 467 MW with solar input of 17 MW and is in operation since 2009.

The Martin Next Generation Solar Energy Center is a 75 MW solar natural gas hybrid plant in the United States. Florida Light and Power integrated it into a 3705 MW combined-cycle plant and began operation in 2010. The 1 MW plant in Saguaro, Arizona, was built right next to a fossil fuel power plant with the option for combined cycle in the future. The 570 MW Victorville 2 Hybrid Power Project and the Palmdale Hybrid Power Project in South California will both combine 50 MW from solar thermal to a total output of 570 MW, with plans to begin operation in 2013.

The prototype coal solar hybrid plant Cameo was built by Abengoa Solar near Grand Junction, Colorado and began operation in 2010. It has a solar output of 4 MW coupled to a total capacity of 48 MW.

Two more Abengoa projects are the Agua Prieta solar field in Mexico (Sonora), which will produce 14 MW and eventually be combined to a total of 478 MW. In the Atacama desert in Chile, parabolic troughs will deliver more than half of the necessary process heat for a Minera el Tesoro copper mine. Archimede (the first plant to use molten salt for heat transfer and storage) in Sicily, Italy, is integrated into a 130 MW combined-cycle steam turbine, with solar input of 5 MW. It began operation in 2010.

In Ningxia, northwest China, Hanas New Energy group is currently constructing Asia’s first ISCC plant. Planned total capacity is about 93 MW, with a goal to be finished in 2013.

ISCC technology is on the one hand beneficial for the solar power plant side by enhancing reliable and consistent power output and reducing costs in many ways. However, it also enhances overall efficiency of the conventional combined cycle power plant by contributing to the thermal energy input and supporting steam production needed for the shared steam turbine.