Revolutionary Changes in Ink Jet Technology

How It Was Done

We all understand the Gutenburg press, where the press is inked and then placed down onto the paper. Alternatively the press is inked and the paper is brought up to it. Variations on this process operate today, although sometimes superceded by newer technology.

The newer technology includes inkjet and laser printing. With inkjet the press does not actually touch the paper or object printed but comes very close and squirts ink onto the object.The ink dries. With laser printing the surface for the ink is heated so the ink will stick where it is needed.

Inkjet Advantages

The tremendous advantage of inkjet is that it is significantly cheaper than competing technologies. Only the ink actually needed is used. There is no need to heat the product upon which the ink is to be placed, nor the ink itself.

Laser aficionados will say that laser gives a fineness and accuracy not available on inkjet. And laser deals with curved products much better than inkjet which realistically works well only on flat surfaces. This was true until about two years ago.

Recent Inkjet Technology Improvements

Problems with inkjets have often put people off. One concern is that sometimes a nozzle become blocked causing the picture or design to be fuzzed or otherwise substandard. If you have printed onto a finished product the product is unsaleable, leading to considerable loss.

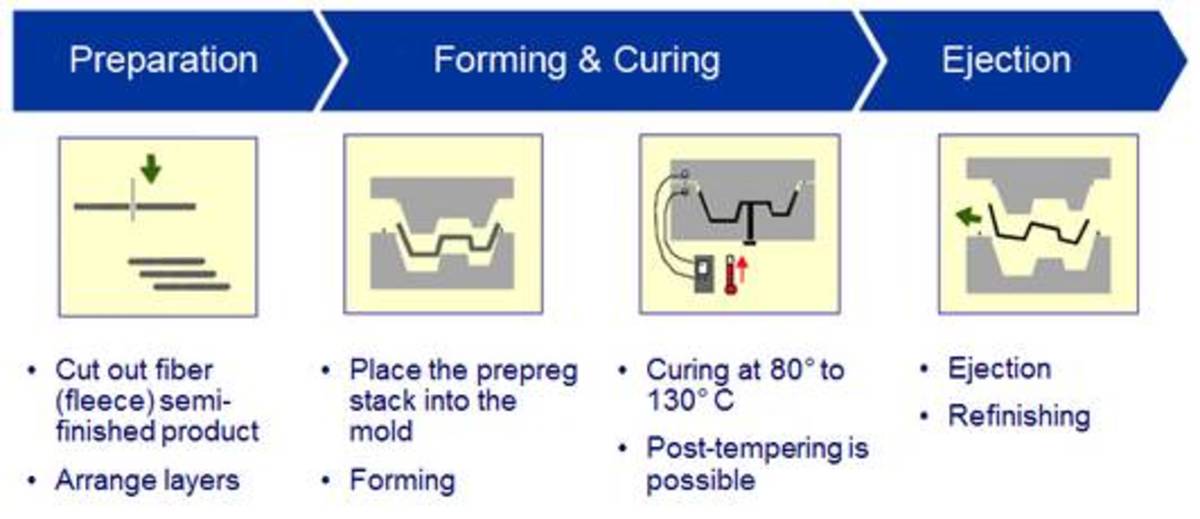

Inkjet's problems with curved surfaces have been worked on, with recently developed better nozzle design and recently developed better inks.

The culmination of these advances in technology is that companies such as Cyan Tec can now offer manufacturers and others everything they are likely to need, cheaper than alternative technologies.

Cyan Tec

The Cyan Tec company are in the forefront of this inkjet technology development. They provide turnkey operations and will work with customers to design exactly what the client requires. They will provide everything including inspection machinery, the special inks and inkjet heads, maintenance training and stacking facilities.

One new advantage is that with computer controls the manufacturer is able to switch the design instantaneously, many times a minute. For some products this is hugely useful.

The contact details are: Cyan Tec, 39 Hayhill Industrial Estate, Barrow upon Soar,

Leicestershire UK LE12 8LD

www.cyan-tec.com, T +44 (0)1865 377885, E mail@cyan-tec.com