How to Bend Square Tubing

I Need to Bend Some Tubing

My current project is requiring that I bend some square tubing. If you want to bend square tubing you need to square tubing bender. Thanks to my buddy Ed Hanyzewski, I've been using one in his shop for years. Now it's time for me to have one in my own shop. It's simply a gizmo that hooks onto the hydraulic press. Here is a picture of the press.

The key to bending square stock is “poke it” on the top flat surface and push it down between two points causing the top surface to dimple. So I am going to need two parts, the "Poker" and the "Holder".

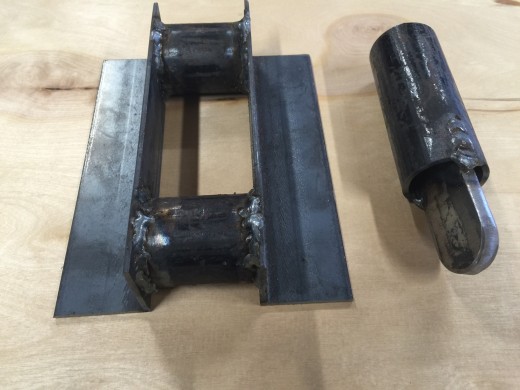

The "Poker"

I’m going to need a piece of pipe that fits over the hydraulic ram. I will need a heavy piece of metal to weld to the end of it, you know the part that pokes the metal. This all slides on the end of the ram as pictured:

I want that piece of steel that make up the poker to be as thick as possible but we are only bending square stock that is ¾’ inch wide. If the poker is ¾” wide it will not dimple the metal but rather smash it, so it must be ¼” to 3/8” wide. I’ll go with 3/8” because 3/8 is half of 3/4 and it is stiffer. The stock I find is 1 ½” wide, 3/8” thick. I need a piece long enough to go up inside the tube to give it strength. I select 5 inches. Two inches will be welded inside the tube and 3 inches will stick out. Before I weld it in place I need to round off the end. So off to the grinder I go to approximate a 1 ½’ radius on the end of the poker.

Note to self: Don’t weld the rounded end of the poker up inside the holder. Make sure the rounded part is sticking out.

I can’t weld up inside the tube so I grind two slots on each side of the tube. Then I place the poker in the tube and stop. What was it I was supposed to remember? Oh ya, rounded end sticks out. I weld the sides of the poker in the groove – filling the grove as I move along. It makes for a very secure weld.

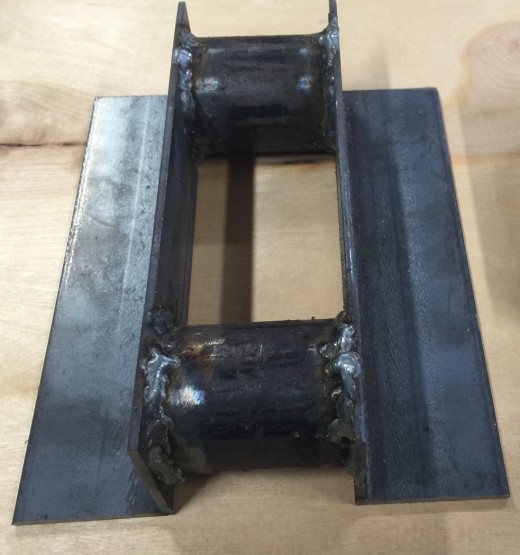

The "Holder"

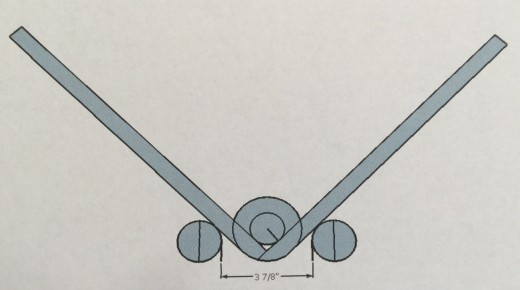

Now I need a holder. As you bend the square tubing it slides down between the two supports. You can make a holder were both supports pivot which would be slick. Or you can take the K.I.S.S. plan of attack and Keep It Simple Stupid. I choose two pieces of the same pipe welded to two pieces of angle iron. Sounds simple and bullet proof. But now here comes the math. How far apart do the two holders need to be. And the answer is let's go to Sketchup and draw this out. Your square stock is 3/4'” square. The radius of the poker is 1 ½” so the minimum distance is ¾” + ¾” + 1 ½” which equals 3" but that will get tight and make it hard to remove the bent tubing. If I draw this out and adjust it to show the poker and the square tubing I can slide the holders into place and measure how far apart they are. It looks like this:

Well now all I do is measure the distance between the two holders and I come up with 3 7/8”. Lets call it good at 4” so I weld up the bracket and it turns out fine.

Done

Now I have the parts necessary for my Home Square Tubing Bender.

The Test

Let’s mount it on the Hydraulic press and give it a try. Because of the structure of the press it has to be mounted on the diagonal. You also need to account for the fact that the tubing will lift on both sides as you begin to bend the metal. This means the diagonal will be more than you might initally think. I only need a 23 degree bend so the diagonal will not be much of a problem.

The next step is to mark where you want the bend. I have placed a blue line on the side of the metal over the barcode and I line that up with the center of the “Poker”. I also need to be sure that the “poker” is in the middle of the square tube.

Once lined up I start to add pressure to the cylinder. My equipment holds and the tubing bends. See how the “poker” dimples the square tubing. It bends quite nicely.

And the bends look like this:

And after bending two pieces of square tubing in an “identical” fashion I weld in some cross pieces and the frame for my scooter is finished. Well lets go back to that identical concept, it might be better to refer to the two pieces as similar…..

The End

Well it all turned out well. I am gong to add a set screw to the "Poker" to hold it in place on the hydraulic ram then maybe a little paint to clean things up.

Bob Roswick

For other articles by this author visit:

http://hubpages.com/roswick