Structural Steel Fabrication

Structural Steel

Construction is a massive industry world over and the use of structural steel is taking over conventional metals. The alloy is a mixture of molybdenum, nickel, chromium, manganese, and other elements as the case may be, these are mixed with carbon steel to yield the required characteristics.

Structural steel is used to accord shapes to the parts used in building and also to manufacture support structures. Some examples are I Beam, channel, plate, hollow steel structures, rail, tee, bar rod, and angle.

Steel Gates

Video - Structural Steel Fabrication

Beam

Building Parts

Lightweight structural steel is also used as building components or parts. These are common structures that accord usability to a building commercial or residential. Some of the components are windows, gates, ladders, grills, railings, fences, and guard rails to name a few.

Other related fabricated steel products are burglar bars, steel window guards, roof railings, basement doors, chain security gates, and so on.

Expanded metal mesh is used to make cages, guard rails, welded wire mesh staircases, and so on.

Expanded Steel Metal

More on Stuctural Steel

Properties of Structural Steel

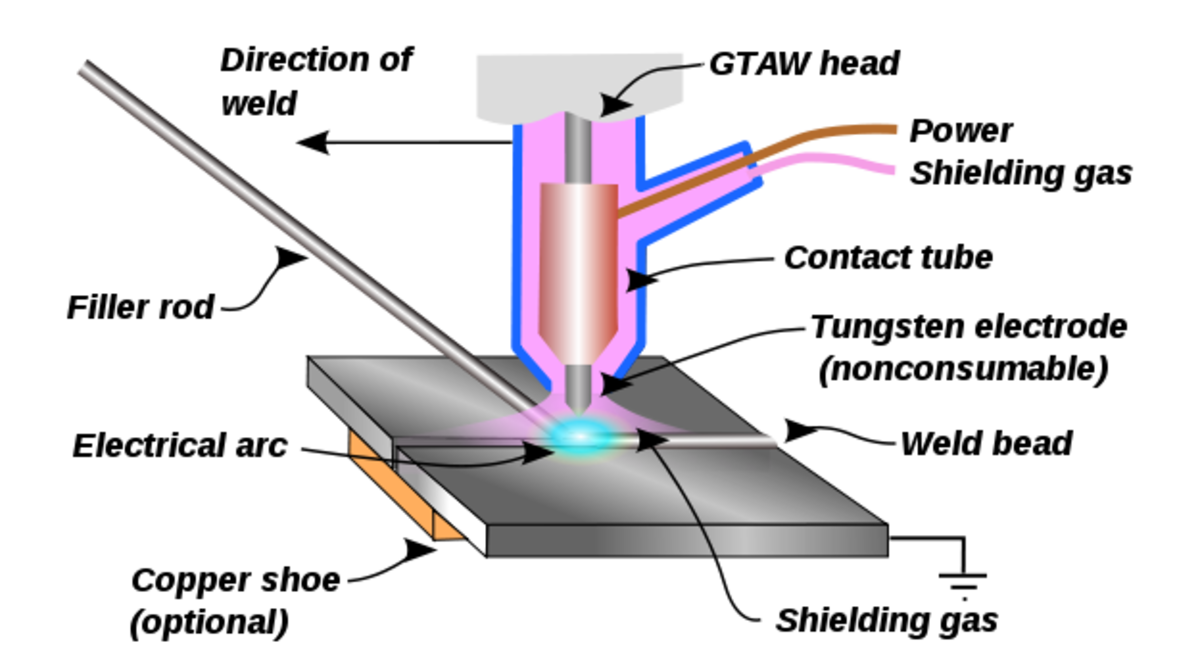

Though the metal alloy can be varied by mixing different proportions of chemicals the property remains nearly the same. Lightweight is one of the characteristic features of structural steel. It is ductile and malleable and hence can take any shape. The product fabricated are of high tensile strength, they are durable and tough. The metal alloy can be welded which is why it is possible to create products for construction.

The chemical combinations accord the metal good mechanical properties. The addition of some chemicals in trace amounts makes the metal very useful during fabrication. This is crucial for during manufacture mechanical stress and heat are applied to the metal and it should be able to withstand it.

The steel is resistant to corrosion and extreme temperatures after the application of protective paint. In the case of molds, no such protection is needed since it forms a less suitable environment for them.

In the case of a construction site being in the vicinity, there is a definite cost benefit of this metal as compared with reinforced concrete. Prefabricated products are transported to the site and installed quickly thus saving time as well.

Photo Fabrication

Fabrication Shops

Modern-day fabrication units are termed shops wherein products using structural steel are designed, created, and installed at the construction site. Not as simple as presumed the procedure may be complex.

A number of activities are carried out as per the maturity or type of manufacture involved. The product design is crucial since they have to be accorded the requisite shape and size in addition to the properties the end products should contain.

Some of the processes involved in post-designing are bending, cutting, blacksmithing, forming, burning, and so on. Machining is done to accord a smooth finish and assembling may be involved as well. The fabrication is a task that requires the expertise and experience of the workers besides a well-equipped infrastructure.

Video Fabrication

Metal Fabrication Future

The metal fabrication industry is linked with the state of the construction industry. In the USA the future is bright thanks to the rising economy which is a healthy trend. At the moment demand exceeds supply as recycling is limited. Hence with construction rising, the industry is in a better future.

Emerging trends indicate higher demand for steel products as contemporary fashion suggests. Restaurants, cafes, and fast food joints all express a proclivity towards structural steel fabricated products. Homes and commercial structures are seeking contemporary themes and steel products gel well with this trend.

Computerization as a result of technological advances along with robotics will fetch a paradigm shift in the industry for the better. Well-designed and manufactured products are the future of this industry. Hence fabrication shops have to keep in tandem with emerging technologies. Overall as far as individual units are concerned the future depends upon management and efficient manufacturing practices.

With prefabrication construction taking a firm hold the industry has to meet the demand and supply gaps efficiently. This would mean high stakes for metal shops in the coming future.

Roof Installation

This content is accurate and true to the best of the author’s knowledge and is not meant to substitute for formal and individualized advice from a qualified professional.

© 2017 Uday Patel