Thermography 101, A Conversation About Emissivity

About Emissivity

In physics thermal energy conducts to the surface and then a percentage (expressed as a decimal) emits from the surface which the remainder reflects back into the mass. This ratio or dimensionless number is called the items emissivity.

I was having a conversation with a thermographer who apparently needed more schooling. This conversation if fictionalized, but contains the basic talking points of the conversation.

Infrared, not for amateurs

Infrared Images

The Conversation

“Set the emissivity to one,” said he, “as most thermographers do. It helps to get a good reading.” My interlocutor was telling me how he sets his thermographic camera. We were discussing emissivity settings on radiometers, thermographic cameras, and how they are being used or ought to be used.

“Accuracy,” said I, “is a vital part of what you called a ‘good reading.’ Accuracy cannot result from an image made using the wrong emissivity rating.”

“Manufacturers,” said he, “recommend a setting of one if the emissivity is less than 0.60. Since it can be confusing and you can take a reading off of something else with a higher emissivity close by, it simplifies the process.”

“Science,” said I, “strives for accuracy. Since Joule, precision has been the order of the day; he defined the first law of thermodynamics. I can’t see how anyone can justify properly adjusting for emissivity until it becomes the most important issue in determining the temperature of an item, and then avoiding it at best or ignoring it at worst. The ISO Standard seems to understand this as does the NETA standard, but many who use lower assessment criteria seem either to forget it, ignore it, or find a cheat or work around, a shortcut of sorts that science condemns.”

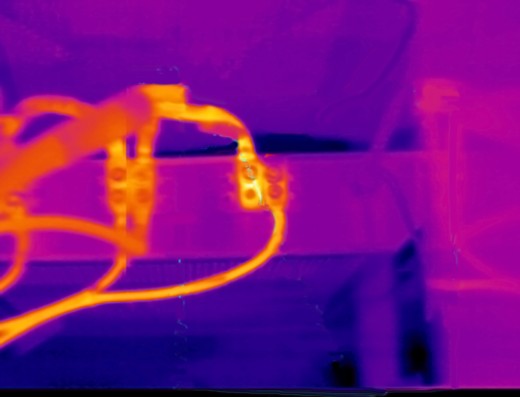

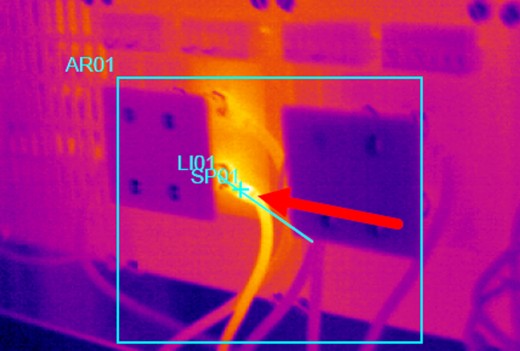

“Practice,” said he, “forces them to use a different item for an accurate emissivity ratio if the emissivity is too low. For instance, changing the reading from a shiny connector with an emissivity of, say 0.20 to the insulation where the emissivity may approach 0.90. It improves general readings.”

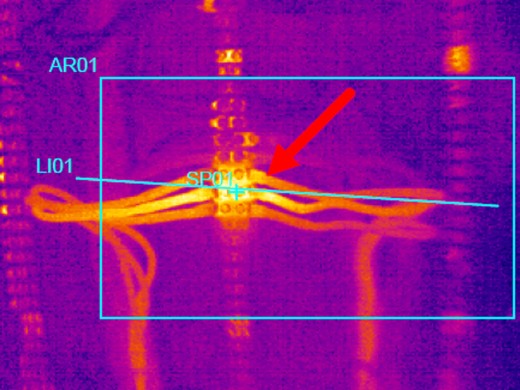

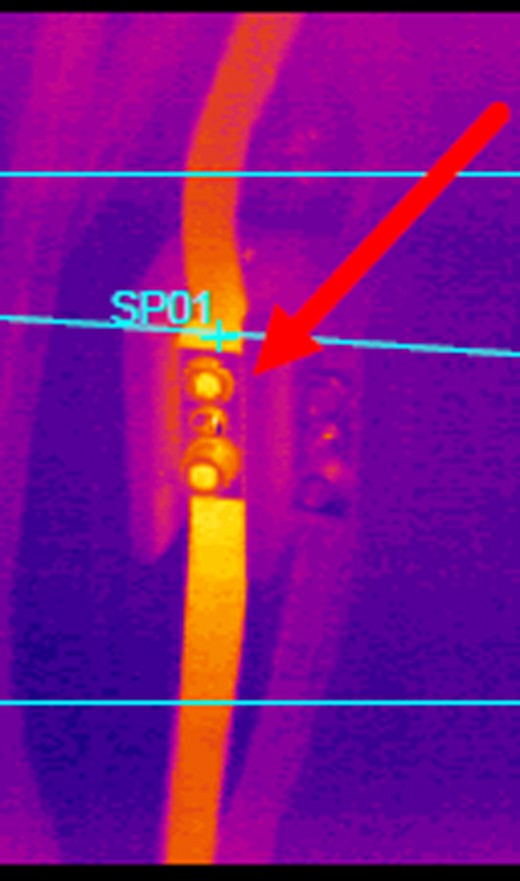

“Precision assessment,” said I, “metrics, and correct assessment of the problem at hand, it would seem to me, is more critical than convenience. The greater the mission criticality, the greater the dependence on a given machine or connection, the higher the demand for the equipment, the more critical an accurate assessment of risk becomes. The more critical the environment, the more critical it becomes. On a ship, for instance, it can be life and death. Let’s make up simple numbers, and using an emissivity below that 0.60 threshold you mentioned. For emphasis, let’s go well below that. Let the problem be a ventilation motor controller in a ship engine room where we find a bright shiny new wire with a crimp on connector with an emissivity of 0.20, and a small issue with a slightly dirty connector post and apparent temperature rise of 12oC. The insulation is also shiny and new and the background accurately measured at 20oC. What does the thermographer who used an emissivity of one see on the connector? How will he rate this problem? But before you answer understand this was a problem I identified some twenty five years ago, I was the level one certified thermographer that found this situation.”

“Experience” said he, “tells me you will have seen a reflection which the camera will not eliminate because the emissivity is set at one, it assumes all the energy is coming from the spot and none is reflected either from the background or, conducting to the surface, reflecting back inside, and, on the insulation he will see the 12oC plus the 20oC reflection. You told me earlier you used a different assessment criteria based on older military standards and this classified the problem at the second level, “Important” to pay attention to and you likely suggested it be trended for the next inspection, or corrected if the crew has time or in the next shipyard visit.”

“Blackbody radiation?” I queried, “are there any black bodies in the universe as you imply by setting the emissivity to one?”

“None that are known,” he replied, “but this is a useful generalization for most thermographers.”

“On that we agree,” said I, “black bodies do not exist and we have known this since before Max Planck. However, we are not discussing generalizations or general principals, we are discussing a specific item on a specific ship at a particular time and under certain conditions at the time of inspection.”

“So, what is your point?” he enquired.

“Standards” said I, “do vary, and this is why we teach the use of ISO standards as so important to understand, in general, and to apply, in particulars. In this case, the shiny new insulation had a thin plastic layer with a higher emissivity that expected, forget Fourier and Kirchhoff, that is, ignore the loss of heat over the distance different from your thermographer’s measurement and inch or two away, forget that heat diminishes with distance: The emissivity of the connector is 0.2, and, set correctly the camera ignored the fractional 18oC temperature (that is 20oC x 0.80) reflected from the background and correctly sees the 12oC degrees as a 48oC rise. By the ISO Standard this is a problem needing immediate attention because the increased heat experienced by this connection speeds up the rate of oxidation and, a year later, the ship could have a fire in the engine room which turns off the ventilation fan. Fortunately, this was not the end of the story. I was in training and my instructor recognized the problem and informed the first engineer he needed to take off the connector, not yet oxidized, clean it and the post it connected to. He did so and the problem was gone. This illustrates the importance of proper emissivity settings and the fact that, using a different standard and emissivity of one would have resulting in a critical problem being under reported, the assessment criteria set too low to reflect the current issue at hand.”

“That was twenty five years ago,” said he, “why bring this up now?”

“Because last week a camera manufacturer gave me the same advice as you did: ‘use an emissivity setting of one.’ That is absurd.”

Said he, “What do you think of the new I-Phone infrared app?”

Said I, “It’s both a fun educational tool and potentially dangerous.”

“Whatever do you mean?” He inquired.

“If you use it to understand how heat works, then it’s a fun and interesting educational tool and I highly recommend it. If on the other hand your need to inspect equipment but have had no training, it would be more like me asking Richard Branson if I could fly his space vehicle. Everything would go well for ten minutes and then tragedy would strike. We would have disastrous results. Some engineers will capture their own heat reflecting and try to fix things that are not problems, and others will completely miss things that could start a fire or even sink a ship. The company that issue them has just fractioned their own market for their high end cameras, now, wrongly understood to be outdated and unnecessary. They have shot themselves in the foot but won’t feel the pain for several years.”

Said he, “All that serious?”

Said I, “Yes, quite.”

On Emissivity

© 2015 Ronald A Newcomb