A Quick Introduction to 3D Printing. What's it all about?

What is 3D Printing?

3D Printing has been in the news a lot recently in the last couple of years, and there has been a lot of hype associated with it. Many commentators consider it a massive leap forward, equivalent to the industrial revolution, mass production or the creation of the internet. But what actually is it?

3D Printing is also called ‘additive manufacturing’ and is an industrial process of creating physical objects by gradually adding more and more layers of material. This is distinct from normal manufacturing methods which can be thought of as subtractive manufacturing which mostly involves removing material by cutting, drilling etc.

The other fundamental difference is that 3D printing involves using a digital model to create the physical object. Traditional manufacturing methods often use a physical mould or ‘tooling’ for manufacturing objects and components.

3D Printing in Action

Advantages of 3D Printing

3D Printing has a number of advantages over traditional manufacturing methods.

Impossible designs - This has to be the biggest advantage; that it can easily create certain designs that are all but impossible with traditional methods, such as intricate lattice shapes with lots of tiny gaps in and be used somewhere like space.

Rapid prototyping – While mass production is extremely quick and efficient, the creation of prototypes is a slow, time consuming business involving a lot of skilled but laborious work. If a prototype needs changing ever so slightly, a new prototype needs to be created from scratch. With 3D Printing, the design can be changed in minutes on a computer and then printed out.

Quantity is irrelevant – with most manufacturing, the greater the quantities the cheaper the unit price of production. This is because most of the cost is in the tooling and initial setup. With 3D printing, the unit price (after design costs) is the same no matter the quantity being made. Items that have a niche market only might not be viable to manufacture using traditional methods, but would be cost effective if 3D printed.

Print at Home or on site – Imagine suddenly needing a particular tool for a DIY project, a part for a piece of equipment or maybe just something fun like a peculiar shaped cookie cutter when doing some baking with your children. Normally you would have to go out to the shops and look for it, or order online and wait a few days for it to arrive. If you had a 3D printer, you could instead find a suitable design online (or create one yourself if you preferred) and print it out at home there and then. The same principle applies to businesses who need to create parts or tools on site, possibly a long way from any sort of manufacturing facilities (NASA is the perfect example of this as they are developing 3D printers to work in space).

Video introduction to 3D printing

Materials

The most common type of material used in 3D printing is plastic. In particular thermoplastics, a type of plastic that melts into a liquid that can be injected, but sets and hardens when cool. This is the type of material commonly used in home & hobbyist 3D printers.

There are a variety of other materials that are used in 3D printing, mainly for industrial use. These include metal, ceramics and even food. Expect the materials used to diversify as time progresses.

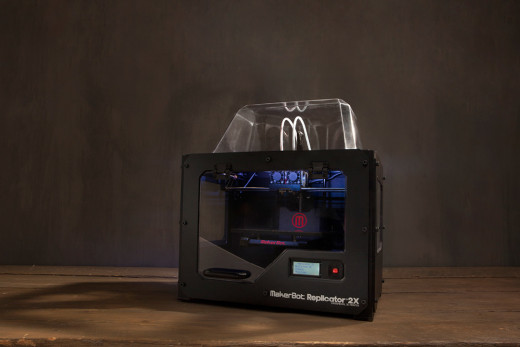

A 3D Printer

Implications of 3D Printing

3D Printing is getting a lot of press at the moment, but what can we expect to happen in the next few years?

Affordability – The price of 3D printers has been coming down a lot over the last year or two, and this trend is set to continue. The price of some of the more popular models has dropped well below $1,000 which is quite a critical price as below this it becomes reasonably affordable for keen hobbyists. As the price continues to drop below the $500 mark, it starts to get into the price range where it becomes affordable for home users. You can already get this, but not yet by any well known retailers or on mainstream websites or from retailers that are trusted and pushing it into the market. However on some sites you can design and have someone print your own 3D designs.

Easier Designs & 3D Scanning – One of the obstacles to mass take up of 3D printing is the relative difficulty in designing 3D printed objects. There is a variety of software, much of it which has quite a steep learning curve. Software will get easier to use, which will help this. Recently Adobe announced that its Photoshop image editing software will start being able to create designs for 3D printing which is a huge step forward. The next step after simple software is 3D scanners which will do away with the need for software entirely – for simple designs anyway. These are a few years away but are being developed by a number of companies.

Economic Revolution – 3D printing could potentially revolutionise manufacturing, massively reducing product development time and leading to mass customisation. It could also lead to a shift in manufacturing activity away from Asia and back to developed countries in North America & Europe.