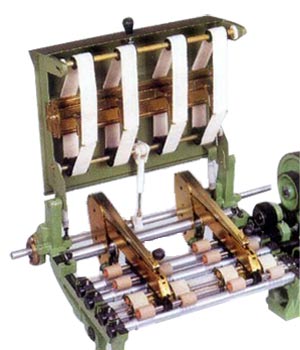

Yarn Spinning - Speed Frames.See Video

Drafting to Pre Spinning.

Pre-Spinning.

We have come from Blow Room to Carding to Draw Frames and now we enter the Frames Department also called as Roving department or Simplex Department.The Second Passage Draw Frame Sliver is fed to this frame and it passes between four pair of rollers,the bottom rollers are of steel with small flutes over which are rollers held by spring loaded arms holding steel shells covered with rubber cots.In the picture there are rollers one above the other but with rubber cots at the top in the Back zone and a Rubber Apron Covered Rubber Roller over the 2nd,3rd,and Front rollers showing the passage of slivers over the rollers.The Back rollers are termed as Break Draft Zone,a zone where the sliver is drafted and condensed and they enter the next zone with no draft or a zero plus draft so that there is no sagging.This sliver is now drawn or drafted now enters the third pair of rollers where further it is drawn or drafted as per spinning of final yarn number ( Count ).Now it enters the final front zone that gives the required final draft.This is now given a number as count prior to final spinning as it emerges out of front rollers called Roving Count.The count is usually from 1.0 to 2.5 and may extend to 3.0 also in rare cases.The meaning of Count as in British System which is followed by us in India as it was the British who established the textile mills in India.It is universal system till the EU countries entered the shores of India and we did manage to follow their system also when ever they asked for our yarn or cloth.The Count as per British System means the length of 840 yards of material that weighs one pound and is called as 1s Count.The weight is constant and it is the length that is taken to name the count.In Fly Frame Department the count that is maximum except in certain cases is 3.0s Count.This condensed drafted sliver now called as rove is twisted and wound in to packages of up to 1.5 kg in these Fly Frames.It is called as Fly Frame on account of the Fly'ers that take the drafted sliver revolving like flying around a spindle turning at a given speed.The package is built layer by layer with a system by use of a variation of the the lift timed to give a shape of package that will hold the soft low twisted rove,required to unwind at the spinning with out any break as it is drawn by the spinning rollers.In good old days it was done in 4 stages called as Slubber,Inter,Rover and Jack frames.This was simply revolutionized by the Japanese in to one and called as Simplex Frame which again they bypassed to direct spinning called as Sliver Spinning,which was a failure though.However the Simplex now improved by the Swiss Technology has not been replaced in case of Fine Counts in the spinning mills or section of a Textile Mills.We now go to Spinning.