sheet metal brackets

Mild steel angle brackets with a zinc plated and clear passivated treatment

Sheet metal angle brackets and their manufacture

Sheet metal angle brackets in whatever material can be very helpful when used on their own or within fabricated assemblies. They may simply be mild steel fixing angles to enable 2 components to be fixed together, perhaps a method of increasing the local thickness of a thin metal housing or a reinforcing point for wall fixing. Brackets and angles can be made from sheet metal in thicknesses from 0.7mm to 6.0mm thick. CNC punching machines can be used to punch out the brackets from flat sheets in a matrix known as a sheet nest. The holes, slots, angle notched or radius corners can all be added at this CNC punching stage. Once the components have been punched out they can have sharp edges or larger burrs removed before they are bent up to size.

Sometimes angle brackets can be sawed from angle section if a simple bracket is required. These angle brackets are stronger but limited in their detail so tend to be for simpler mounting angles.

The uses for brackets and angles is endless with the finished component often never seen to the end customer, look under the bonnet of any car and you will see plenty of examples of sheet metal pressed brackets doing a job that is never normally seen.

To see videos on manufacturing machines being used to produce bracket and examples of past projects please take a look below.

There are more examples of brackets and angles at http://www.vandf.co.uk/gallery/sheet-metal-bracket/

Manufacturing Videos showing the production processes used to manufacture sheet metal brackets

Here are a few videos showing different sheet metal brackets being CNC punched out and CNC bent up using Trumpf manufacturing equipment. These machines are perfect for manufacturing angle brackets from a range of sheet metal materials in volumes from just 1 or 2 samples right up to many thousands. There are so many designs and styles of brackets and angles that can be manufactured, most being bespoke to a customer's requirements that it's impossible to cover everything in one Hubb page but we have tried our best here to give you an idea of what can be manufactured with modern CNC techniques.

As we don't use dedicated press tooling to manufacture brackets we have the flexibility to produce them with our free standard tooling. The standard tooling can be either CNC punch press tooling e.g. circles, squares, rectangles and form tools or CNC press brake top and bottom V block tooling. As the press brake tooling is used as air bend tooling the same tooling can be used to bend anywhere from 179 degree to 28 degree inclusive angle. For a complete bend safe edge on a bracket we use special safe edge or dutch fold tooling. These methods of manufacturing enables our customers to change their minds on design details e.g. material type, thickness, holes and profile size without any impact on the tooling. This flexibility in production is typical of CNC machines and their impact on modern manufacturing method today.

Bending mild steel sheet metal brackets on a small Guifil CNC press brake

Electronic chassis bracket being bent on a Trumpf 7036 CNC press brake

Motor support brackets being CNC punched and bent on a Trumpf 3000R CNC punch press

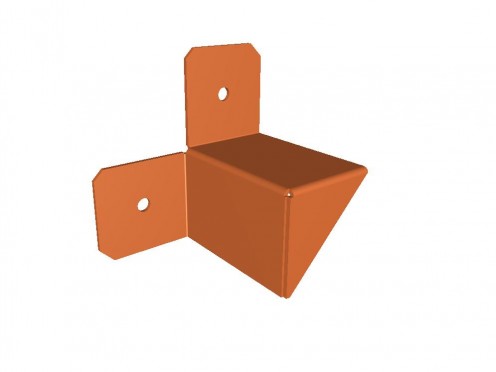

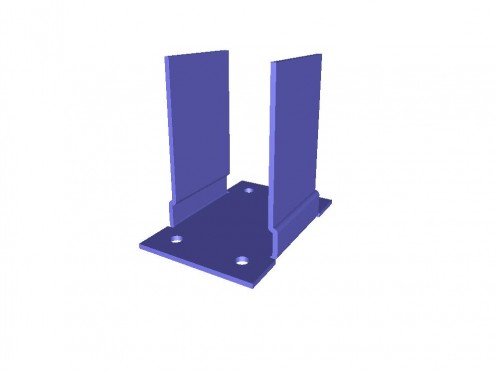

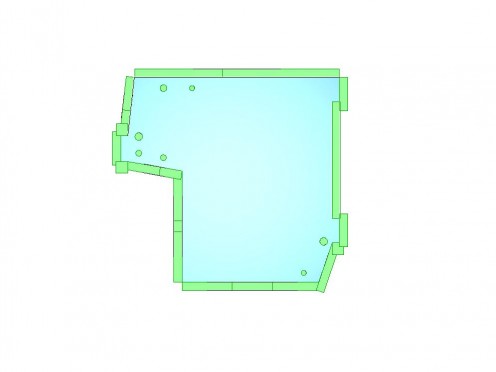

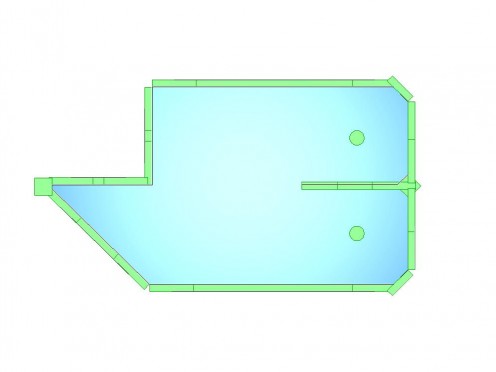

Typical sheet metal brackets and angle designs, software models and finish brackets

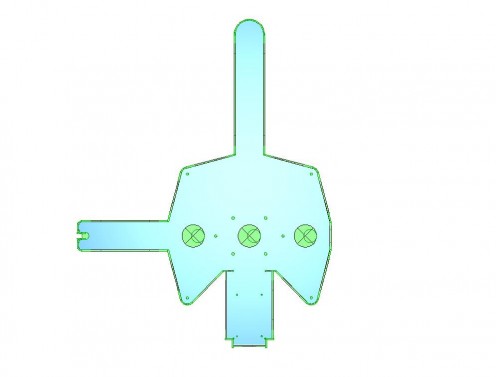

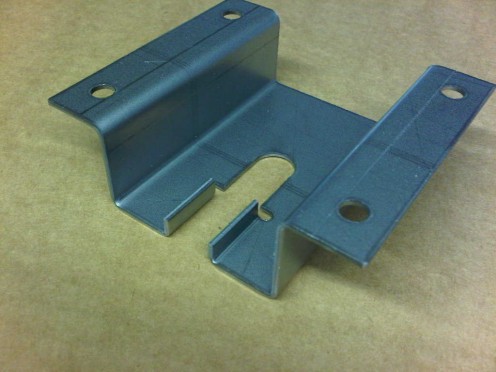

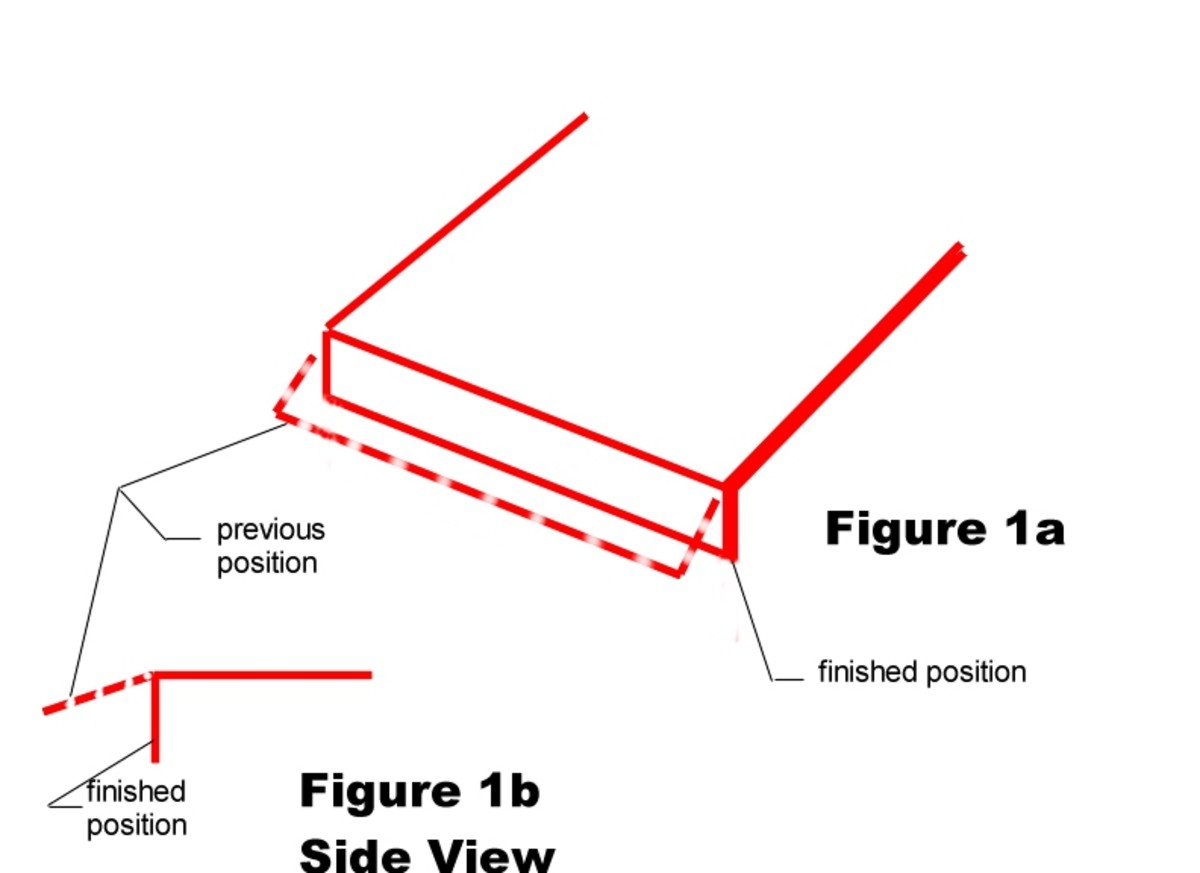

I have listed below some great examples of brackets and angles to illustrate the vast range of parts that can be manufactured from sheet metal materials, flat bar and angle stock materials. Some of the photos are of existing brackets that have been manufactured in the past and some are 3D software models showing various brackets before they are put through CNC punching software and then into actual production. You can see from the range of parts CNC programmed that the CNC piunching process is very flexible (batches sizes from just 1 component up to many 1000's off) and can be used for all materials, thicknesses and sizes of angle and bracket.

Can you spot which 3D part is produced from the 2D CNC program?

Sheet metal bracket 3D models, CNC punching programs and real life sheet metal bracket case studies