New Hampshire 2017 Maple Producers Annual Maple Sugar Weekend

New Hampshire Maple Producers Annual Maple Weekend.

As if to celebrate the impending arrival of spring, it is during the late days of March and the early days of April that the sap of the maple begins to flow.

It's a brief time, a few short weeks each year that the New Hampshire maple industry produces close to 90,000 gallons of sticky, sweet syrup. Maple sugaring in New Hampshire occurs during the month of March and April when the nighttime temperatures drop below freezing and daytime temperatures rise above the freezing point. It is at that time, and only that time, that pressure within the tree builds and sap runs.

Whence It Came: The Maple Syrup Story

For most of us, we remember maple syrup from our childhood memories, but who discovered this sweet elixir? Credit has been given to the Native Americans who were apparently the first to discover the usefulness and deliciousness of maple tree sap.

As one popular legend tells it, a Native American chief hurled his tomahawk into a nearby tree, which just so happened to be a maple tree. After the chief removed his tomahawk, the clear liquid began to drip from the tree and collected into some sort of container which had been placed below the tree's open gash.

Early European settlers, who had been trading with the Native Americans for maple sugar, would eventually be shown the maple sugaring process so they could make maple products for themselves.

The Process of Maple Sugaring

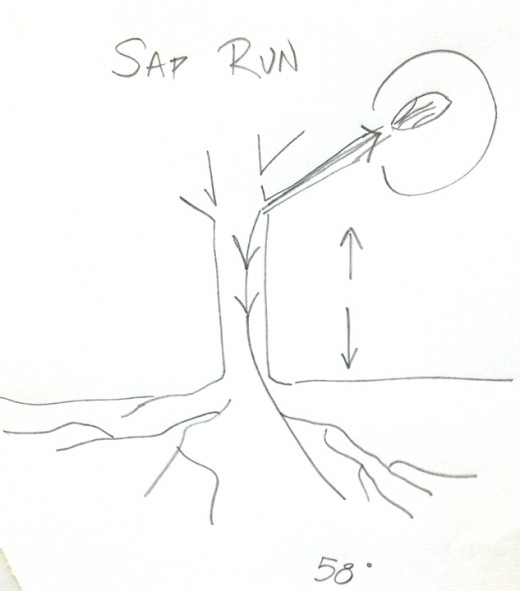

Early in the spring when the maple trees are still dormant, like the people of New England, temperatures rise above freezing during the day and the sun shines brighter than it has in previous months. But, the temperature drops back down below freezing at night creating a fluctuation in air temperature that is necessary for sap to flow.

It is during these periods of warmth when the temperatures rise and create the necessary pressure that develops within the tree. This pressure causes the sap to flow down and out from the tree through the tap hole. During the cooler periods when the temperatures fall back and night returns to a frosty chill, suction is created drawing water into the tree from its roots. This suction replenishes the sap in the tree allowing the flow of sap to run when day breaks and the mercury crawls to at least 40 degrees.

This rise and fall of temperature plays a vital role in the production of maple syrup. If Mother Nature is fickle and temperatures aren't as rhythmic as they need to be there will be less sap and, therefore, less maple syrup. Cold nights and warm sunny spring days are needed for a good maple harvest.

In late February, you may see maple produces tapping their sugar maples by drilling a small hole in the trunk of the tree and inserting a spout into the wound. Either a bucket or plastic tubing is fastened to the spout. Crystal-clear sap drips from the spout and is collected and brought to the sugarhouse where it is boiled down over a blazing hot fire. Billows of steam rise from the evaporator pans as the sap becomes more concentrated until it finally reaches the proper density to be classified as syrup.

Today’s modern evaporators are made of food safe stainless steel and although the design of the evaporator has not changed much since it first appeared in the 1880s its role in this process is integral.

It takes about 43 gallons of sap to make one gallon of maple syrup because sap is about 98% water. Sugar makers boil off most of the water over a wood fire or more contemporary technology. What ultimately remains is a brown sweet syrup.

These days, many sugar producers have foregone the more labor-intensive buckets, in favor of a tubing system. The holes bored in sugar maples in early spring are usually made with a cordless drill. Sugar makers insert small plastic spouts into those holes and connect the spouts to webs of plastic tubing that route the precious sap into large tanks. Many of these sugar houses may even have vacuum systems that suck the sap through sagging lines, along with oil-fueled furnaces and reverse osmosis filters that remove some water prior to boiling. The technology has changed dramatically over time, but in essence the process is virtually the same.

TAPPING SUGAR MAPLE TREES IN NH FOR MAPLE SYRUP!

An Interview with Mr. Pooch Baker

I had the pleasure of talking with Pooch Baker, a long-time resident of Warner, New Hampshire who has been producing maple syrup for years.

Mr. Baker has groomed the hills surrounding his home with both new and traditional technologies in order to capture the running sap from the many maple trees that speckle his property.

The photograph of the sap bucket that highlights this article is one of many that belong to Mr. Baker. When I sat with him to ask a few questions about maple syrup, he was more than happy to teach me.

GG: When did you begin producing maple syrup?

PB: Oh, about forty years ago or so.

GG: What method do you boil your sap?

PB: I use a traditional and renewable method; wood.

GG: How many trees do you tap each season?

PB: About 600 trees. I use both lines and buckets. Using the lines takes time and I'm still working on more. It is an ongoing process.

GG: Do you sell your syrup?

PB: I do, but like many of the producers that I know, I began making syrup for myself and my family. In good seasons, I can make enough to sell, but like last year (2014, at the time of this interview) I only had enough for my own use.

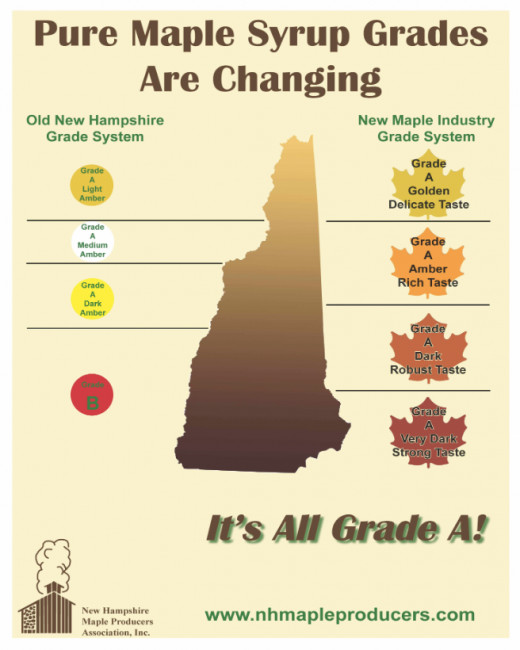

GG: Can you explain the grading system?

PB: New Hampshire uses the Vermont grading system. That will change in the near future, but generally, there has not been a central grading system. The darker the syrup the stronger the maple taste - that is a general rule. Grade A syrup is sold as Light, Medium and Dark. B Grade syrup is used for cooking.

*Since this interview, the grading system has officially changed and all maple producers are required to use this new system. If you're interested in learning more about how syrups are graded, visit the NH Maple Producer's Association.

Here's an interesting fact; all the maple syrup in the world is made within 500 miles of the Great Lakes. The largest producers, that I know of, are Vermont, New Hampshire, Maine, New York and Wisconsin.

GG: How much sap is needed to produce syrup?

PB: 43 gallons of raw sap equals 1 gallon of maple syrup. It's a great deal of work producing maple syrup and it can be a very expensive hobby or business, which is why it is often referred to as "liquid gold".

GG: I've just recently heard of the expression, "leather aprons". What does that mean?

PB: Leather aprons were once worn by the old timers that were working the fire that heated the sap. When you pour warm syrup over fresh snow, as a treat, it hardens and looks like a leather apron. Today, I think most people call it sugar-on-snow.

PB: I've got another interesting, less know, fact. Sap will spoil faster than raw milk.

GG: Do you think the buckets or the lines work best?

PB: They each have their own benefits. Technology improves the process, however. Smaller spouts are being used these days so that the holes in the trees heal faster.

A Tour of the Lassonde Maple Orchard

Within walking distance from my home, perched high on a hill, sits the sugar house of Don and Barbara Lassonde. They have been making syrup for over forty years. Barbara is the former publicist for the Maple Producers, serving nearly seventeen years. Don was the secretary for ten years. They own a beautiful fourteen acre property and more than half of it has sap lines. Each year during the maple weekend festivities, they hang a few buckets near their maple house for the kids to empty, but of their 300 taps, those are mazed together using tubing.

Over the years, the Lassondes have been recognized as superior maple producers, as can be attested by their many ribbons tacked to a wall in their sugar house. Barbara has also written the book, "Maple Sugaring in New Hampshire".

More Information Regarding Maple Syrup Grading

I met with Barbara and Don recently and they explained more of the maple grading system to me. Because the grading system has not been consistent from state to state and country to country, it has been confusing for the consumer. A new mandatory grading system has been created and it is now internationally recognized.

As Told by a Local

Visitors Welcome

During the maple season, many New Hampshire maple producers welcome visitors to their sugarhouses to witness the entire process of sugaring. You are likely to see how the sap is gathered, boiled and packaged. You may smell the hot steam rising off the evaporator and feel the hot blast of heat as more wood is placed on the fire.

As you stand in the chill of the early spring air, you’ll certainly want to have a taste of the pure New Hampshire maple syrup as well as the other niceties bestowed on visitors. Producers welcome guests with open-arms and yankee charm.

Some producers offer sugaring-off parties during maple season. One of the main attractions is something called “sugar on snow” or "leather apron", which Pooch Baker mentioned earlier. You may recall enjoying warm syrup drizzled on freshly fallen snow as a child. The maple weekend offers you another opportunity to experience it again.

Nature's Sweetener

As the organic foods movement has grown in recent years, maple syrup's popularity, like that of honey, has increased becoming an attractive alternative to processed cane sugar. Perhaps it is this increased popularity along with seasons of erratic weather that perpetuates the term "liquid gold". Even here in the state of New Hampshire where so much maple is produced, a gallon of maple syrup can fetch $50.00.

Nutritional Highlights:

• Maple syrup has 54 beneficial compounds including manganese and zinc.

• A tablespoon serving of maple syrup contains of 52 calories and 11.9 grams of sugar.

Health Benefits:

• Maple syrup is an excellent source of manganese which is important in energy production and antioxidant defenses.

• Only 2 tablespoons of maple syrup provides approximately 37 percent of our daily value of manganese.

• Because maple syrup is also a source of zinc, it can help decrease the progression of atherosclerosis, help with skin problems such as acne, and help support a healthier prostate and immune system.

[Source: http://doctormurray.com/healing-facts-maple-syrup/]

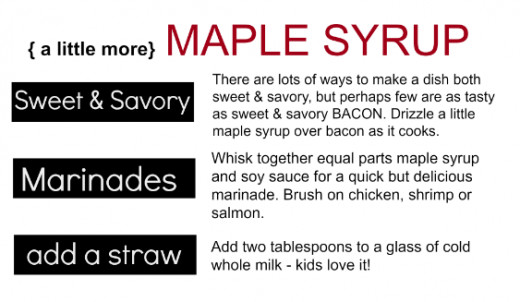

Maple syrup can be used to make so many delicious foods. Most of us are familiar with syrup on pancakes but the flavor of maple, depending on the grade, can be light and barely sweet or robust and multidimensional. Try using maple as a sugar substitute or add a few tablespoons to your favorite BBQ sauce.

Maple Syrup Cake [translation required]

- Plumcake con lo sciroppo d’acero | Sweetie's Home

Maple Syrup Cake

9 of My Favorite Ways to Enjoy Maple Syrup

Pancakes

| French Toast

| Spoonwaffles

|

Monte Cristo Sandwich

| Drizzled over Fried Chicken

| Steel-Cut Oats

|

Butternut Squash

| Belgian Waffles

| Candied Bacon

|

New Hampshire Maple Sugar Houses

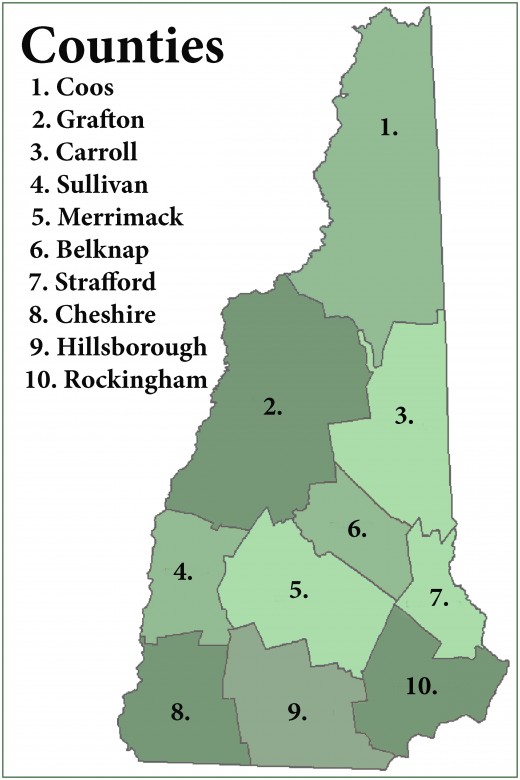

New Hampshire is divided into ten counties and there are maple producers in each. Although New Hampshire is not a large state, it still remains a daunting 9, 350 square mile drive if you intend on seeing every sugar house in the state. Therefore, I would suggest mapping a few houses closest to you and planning a day of it.

Coos and Grafton are the two largest counties. Cheshire, Strafford and Sullivan have the fewest sugar houses. Belknap and Merrimack are in the center of the state and while Carroll county sits to the east, both Hillsborough and Rockingham rest at the south of the state.

Visitors Welcome

If you'd like to visit a sugar house, you should contact any of the maple producers listed above. I would encourage you to contact them first and check on their hours of operation.

The New Hampshire Maple Phone (as they call it) is 603-225-3757. That phone number is typically updated and provides an season report. A list of sugar houses that welcome visitors also appears on the New Hampshire Maple Producers website.

If you're interested in producing your own maple syrup but aren't quite sure how to get started, this article in Mother Earth News is a good way to begin. Learning on your own, however, can be both expensive and hazardous, so reach out to a maple producer and ask for help.