Computer Integrated Manufacturing - CIM

We can see various articles about 'the factory of the future' in the press and other sources which means a fully automated factory that manufactures a wide variety of products without human intervention. Although some “peopleless” factories do exist and others will be built, the major advances being made today occur in manufacturing operations where computers are being integrated into the process to help workers create high-quality products.

Computer-integrated manufacturing (CIM) is an umbrella term for the total integration of product design and engineering, process planning, and manufacturing by means of complex computer systems. Less comprehensive computerized systems for production planning, inventory control, or scheduling are often considered part of CIM. By using these powerful computer systems to integrate all phases of manufacturing, from initial customer order to final shipment, firms hope to increase productivity, improve quality, meet customer needs faster, and offer more flexibility. For example, McDonnell Douglas spent $10 million to introduce CIM in its Florida factory. The computer systems automatically schedule manufacturing tasks, keep track of labor, and send instructions to computer screens at workstations along the assembly line. Eliminating paperwork led to an increase of 30 percent in worker productivity. Less than 1 percent of U.S. manufacturing companies have approached full-scale use of CIM, but more than 40 percent are using one or more elements of CIM technolog.

A recent study asked managers how much their companies invest in several of the technologies that comprise CIM (Boyer, Ward, and Leong, 1996). The study focused on firms in the metal-working industry (i.e., primary metal, fabricated metal, machinery, electronic equipment, and transportation equipment), in which the use of CIM is believed to be most widespread. The study measured investment on a 7 point scale (1 means no investment and 7 means heavy investment). Computer-aided design received the highest average score (5.2), followed by numerically controlled machines (4.8), computer-aided manufacturing (4.0), flexible manufacturing systems (2.5), automated materials handling (2.3), and robots (2.1). Another study across all industries found company expectations for future investments to have the same rank ordering of CIM components (Kim and Miller, 1990). Thus, CIM is an important aspect of technology in manufacturing, but it is just one set of tools that helps many manufacturing firms, even those with high wages, remain competitive in the global marketplace.

These tools are given below. Please click the links to read the details and their potential benefits.

- CIM - Computer the Aided Design and Manufacturing

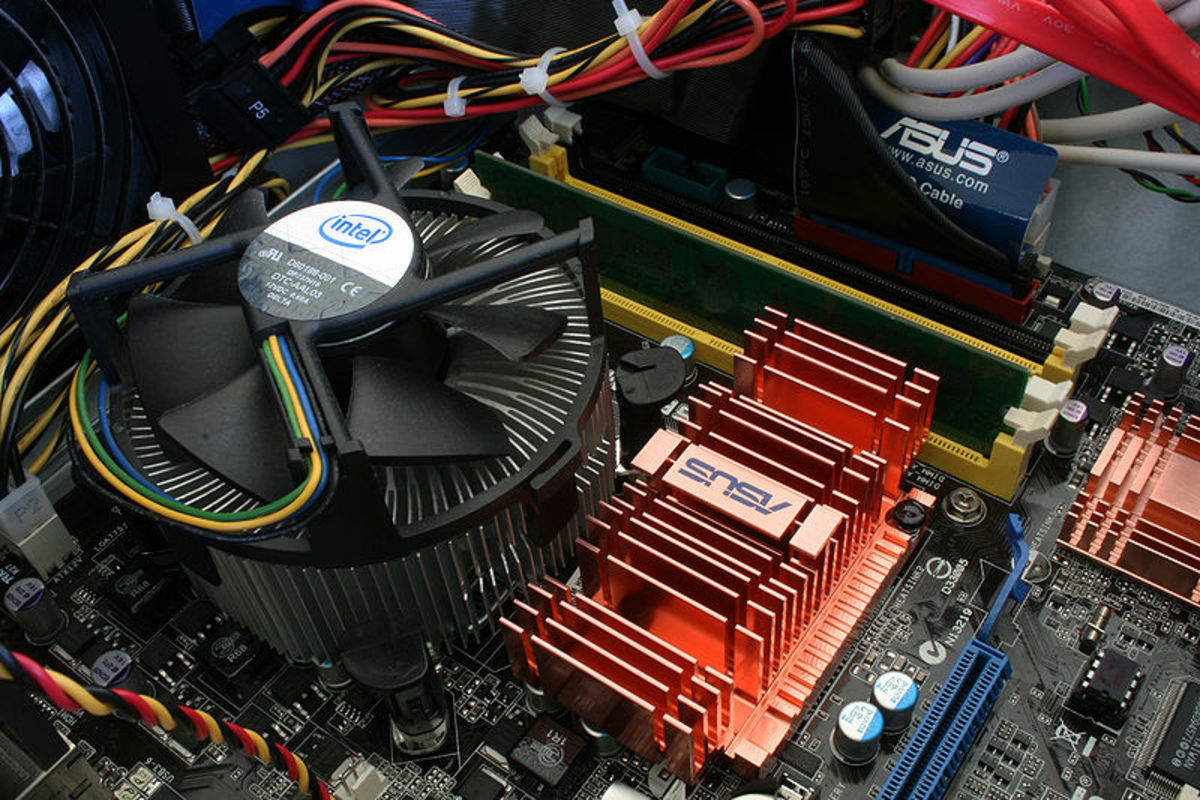

Computer-aided design (CAD) is an electronic system for designing new parts or products or altering existing ones, replacing drafting traditionally done by hand. The component of CIM that deals directly with manufacturing operations is called compute - CIM - Flexible Manufacturing the System

A flexible manufacturing system (FMS) is a configuration of computer-controlled, semiindependent workstations where materials are automatically handled and machine loaded. - CIM - Automated Materials the Handling

Materials handling covers the processes of moving, packaging, and storing a product. Moving, handling, and storing materials cost time and money but add no value to the product. - CIM - Numerically controlled the machines & Industrial Robots

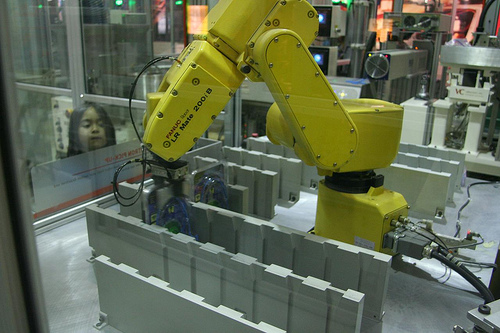

Numerically controlled (NC) machines are large machine tools programmed to produce small- to medium-sized batches of intricate parts. Industrial robots are versatile, computer-controlled machines programmed to perform various tasks.