- HubPages»

- Books, Literature, and Writing»

- Commercial & Creative Writing»

- Creative Writing»

- Humor Writing

Dental Floss Recycling

Are you getting sick and tired of the continually dismal news every evening about the unbudging United States rate of unemployment? Do you happen to be one of the many unfortunates still out of work after 6 months? A year? Two years? Are you stuck in a dead-end no-chance-of-advancement job that doesn’t measure up to your skills, your education, or your dreams of a better life? Have you recently been papering the globe with your résumé? All to no avail?

Well, take heart, because I’m here to tell you that there’s a rapidly growing field of gainful employment at solid wages in the new and growing world of dental floss recycling!

That’s right! You can get in on the ground floor of a truly ‘green’ business (one that is quite literally green over on the mint flavored floss processing floor!)

In recent decades, we have seen the growing concern of Americans everywhere over the environment and times of reduced resources. Many new businesses have arisen to focus on reduction, reclamation, reuse, repurposing, and recycling. It is now common for our fellow citizens to sort, salvage and recycle glass, metals, paper, plastics, aluminum, batteries, cell phones, computers, refrigerants, motor oils, appliances, books, mattresses, clothing, and many other goods. However, dental floss — perhaps because of its exceedingly fine and innocuous presence in our lives — has been one of the last few household product hold-outs.

No more!

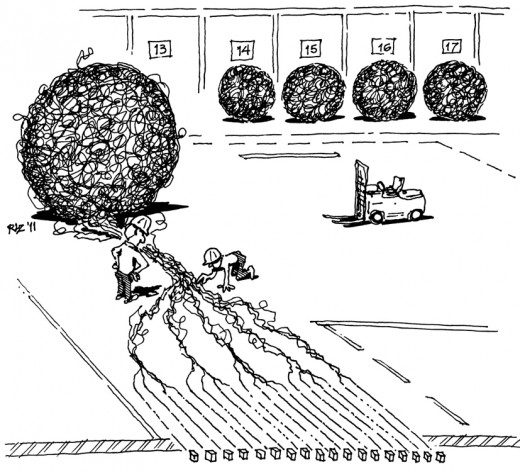

Here we see green employees hard at work in one of the nation’s premier dental floss recycling centers, opened just last month by DentraFresh, LLC, of Lick Skillet, Virginia. As you can see, they’ve got their work cut out for them. In just 21 working days, this groundbreaking facility has already received its first 17 massive floss spheres for processing.

Like most other recycling facilities, this plant operates in a methodical, orderly and proven sequence. First, the immense spheres are hoisted into the Solids Removal Vat (SRV), where thousands of gallons of purified cattle saliva (aided, of course, by any user saliva that might happen to remain on the strands being processed) ease out all the suspended solids: crumbs, seeds, gristle, flecks of spinach, popcorn hulls, etc. Those solids are then used to stoke boilers that heat the SRV and the rest of the plant, and to power the equipment. (Waste not, want not!)

After a quick rinse in fresh running water, the spheres then proceed to the cavernous Drying & Curing Room (DCR), where they remain for an ensuing 96 hours or more. Once dried and cured sufficiently — to make unsnarling as expeditious as possible —they are then brought to the shop floor for the painstaking and meticulous sorting, restranding and packaging tasks.

Workers are now actively being sought to flesh out the ranks of three round-the-clock shifts across more than a dozen processing lines. If you happen to have particularly acute eyesight, fine manual dexterity and motor skills, and a relatively high squeamishness threshold, please apply today! Or simply give us a call, night or day, at 1-800-NEW-FLOS!

- Salesman Extrudes a Greeting

Norbert Jinkmeister says hello [Dateline Levittown, NY; April 17th, 1952] A quiet suburban street, identical to many others, with rows of new postwar ranches aligned in prettily pastel shades down the... - Widetusi Wearing a Bramble Skirt

The 1959 MGM film popularized the supposed Watusi as native African tribal guardians of King Solomons mines. But, in fact, the proper name for the indigenous ethnic... - Bitter Old Lady

Of course, Im bitter! What the @#+*?% else do you expect, you whippersnapper! You try donning some frothy blue-white Bozo-wig to cover your disappearing iron-gray wisps and tell me how you... - Almost Naked Panic

Here we see Ferdinand Lugnut, midway through his audition to appear in a 1962 episode of The Naked City as a private detective being hunted by the gunsels of Murder, Inc.. His audition was... - The Material Museum

If you happen to be traveling anywhere near Cleveland, Ohio this summer, youre going to want to set aside at least a day or two to enjoy the marvels of that newly-opened mecca of...