Briggs OHV repairs

Initial problems

I got a mower in to fix that would not crank past the compression stroke. Jumped the battery. Still no start. Checked for cylinder loaded with gas by taking out the plug. Gas shoot out of the spark plug hole. Be sure you disable the ignition by using a small jumper from the ignition wire attached on the governor/throttle control bracket to ground. Or use one of those remote start switches mechanics use connected to the starter solenoid. Leaving the ign. key in the off position. I did this several times. Same problem. I had taken the fuel line off the carb. to stop any more gas flooding. The engine finally started by using a battery charger connected to the battery. The charger puts out a couple more volts. I fixed the carb. flooding by installing new seat and needle. It still seeps a little so I will install an inline gas shut off valve. You should install one for several reasons. Owner using dirty gas. Alcohol in the gas that is not good to the rubber tipped needle valve. And the needle/seats just not being 100% effective at times. If you still have flooding to the point where the engine dies while idling or after a few minuets of not running, You have to correct this. It may be dirt between the needle and seat. Or a float that doesn't float because of binding or gas inside it. This was common with the the older brass floats. The older Briggs carbs, 1950's through 1980's, had a drain system at the inlet end that let the gas out so you could see if it is flooding. Providing it wasn't a severe leak and the engine was fairly level, the gas would go to the drain and not into the engine. As it does on the OHV verticals. The intake is now at the bottom instead of at the top. This was done so the decompression counter weight can be attached to the cam gear. Why not have the exhaust valve be the decompress valve? Because that led to valve guide wear from hot gases traveling down the valve stem. And maybe some EPA B.S. Briggs could have put on a bigger starter and battery. Just like your auto engine. Then there would be plenty of starter power and no decompress system would be required. The L-head (flat head) engines had about 90 psi compression. The OHV has about 120 psi. So to use the same size starter/ battery it needed some decompression. This led Briggs to design an intake manifold that kept the carb. up at the normal place and now any leakage would flow down into the crank case oil causing the decompression system to wear prematurely. and other parts to also wear.

Blown Head Gasket

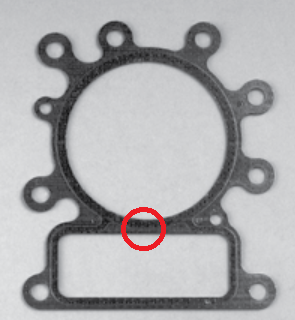

Blown head Gasket

As the pic shows, red circle. this is where most of these gaskets blow. You will notice the wide bolt spacing. If Briggs would have put a bolt in this area, near the red circle, it would have prevented this happening so often. I still think if Briggs would have gone the stronger starter/battery route most of this would not have occurred. Then it would have been easier to control the gas flooding into the crankcase problem also. With the intake back on top you can now have the manifold run down a little away from the intake port. Like the older engines had. It seems to me that all the Briggs engineers have retired and the new batch don't know what they are doing.