Fabric Testing & Others.

Why test a fabric.?

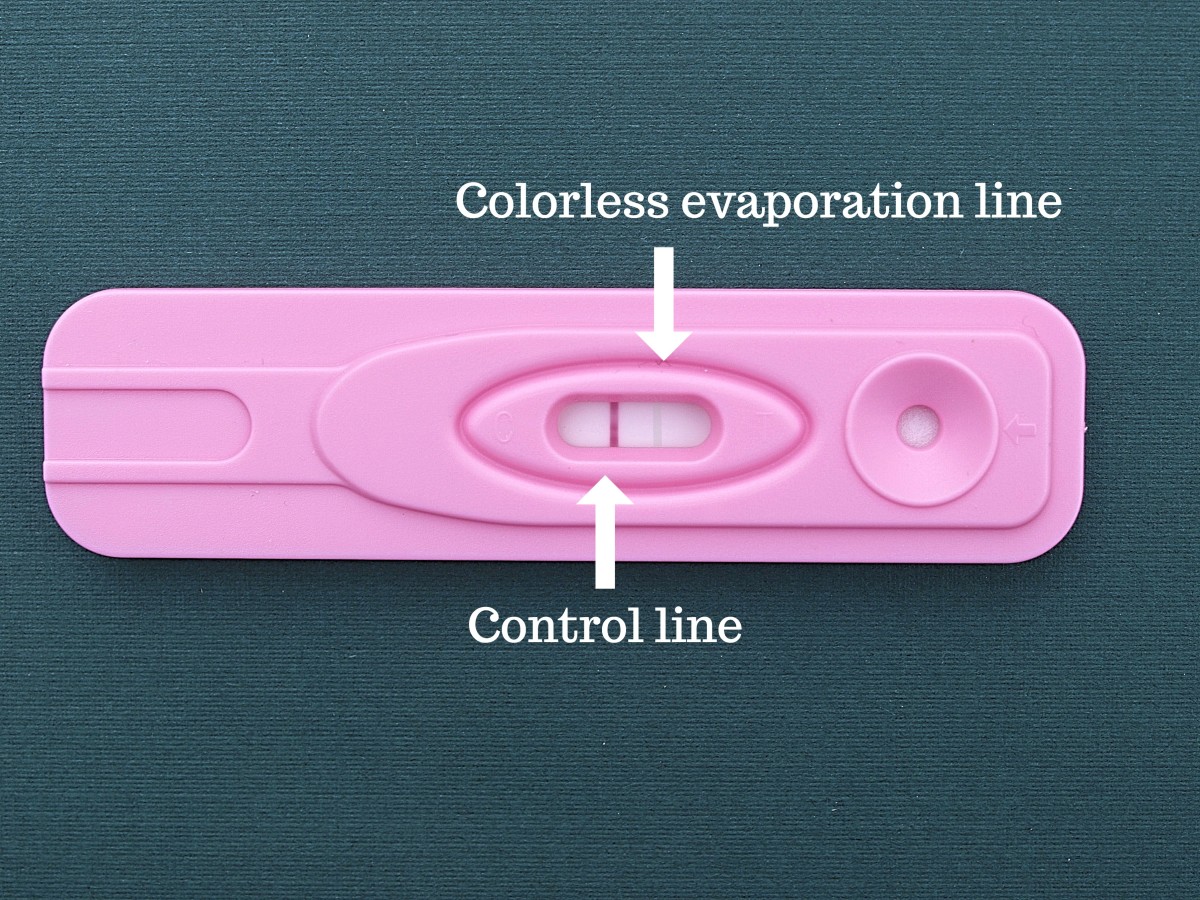

There is nothing that is not tested for Specifications,Standards,Value and for manufacturers satisfaction.We even test the water we drink or the air we breath not to mention our erotic pleasure's.It is therefore very essential to test the fabric we wear or use for any purpose.There are many tests that require testing like,tear strength horizontally called as warp way,vertically called as weft way,thickness,number of threads warp way,number of threads weft way,bursting strength test,tear test,abrasion resistance test,color fastness test,shrinkage test,twist verification test,elongation test,crimp test,width test,defects like stains and missing threads which are visually tested,porosity test,weight per meter test,contamination of foreign fiber test,air permeability test,resistance to insects and pests test,flame test,fluidity test,resistance to electric power test,washing test and in case of shipment to a foreign country we need to get the consumers quality tests that they specify.There are also tests that are carried out by independent research organizations that a buyer will demand.In all the case's the sample to be drawn for testing is also to be followed as per standards followed in the industry to obtain a reliable and consistent value of acceptable quality parameters to build a brand image of the fabric.Most of us buy a branded fabric weather it is woven,non woven,knitted or ready made fabric.

Many of the textile mills had to close down due to just for want of a brand name.The Govt of India ran more than 100 textile mills and had to close down more than 50 mills for want of a good brand image against private textile mills.Even the few mills that are running are not in the list of any product that it manufactures to day.Any number of Ministers of the Govt of India are unable to do anything.The National Textile Corporation in South India had one yarn tester for its 16 mills manufacturing over 10,000 kg of yarn per day and no testing instrument for any fabric with the result over 10 textile mills are closed and many are in the hands of builders cartel who have built multiplexes and high storied buildings.

Just for want of fabric test.

A fabric which may be for use as apparel or for industrial use has got to be tested for various parameters like breaking strength horizontally and vertically termed in technical terms as strength of fabric weft way and strength of fabric warp way.A comparison with standards given for the type of fabric will indicate its quality.There are various standards for every type of fabric that is woven or designed.If you manufacture a fabric you can have your own tester or send it to a organization designated by the govt or research organizations and they charge for such a report. However fabric manufacturers cannot manufacture a fabric with out testing and produce huge quantity and get it rejected just because they did not have a fabric tester for Strength.

Fabric Tester for Shrinkage.

Apparel manufacturers have to necessarily have a tester which measures the fabric for shrinkage other wise the efficiency of the shrinkage machine cannot be determined and there will be complaints by consumers and compensation to be paid.There are so many testing instruments for testing yarn of all kinds and fabric of all types some testings over the machines can be seen in the following Viedeo's

Testing for Fabrics

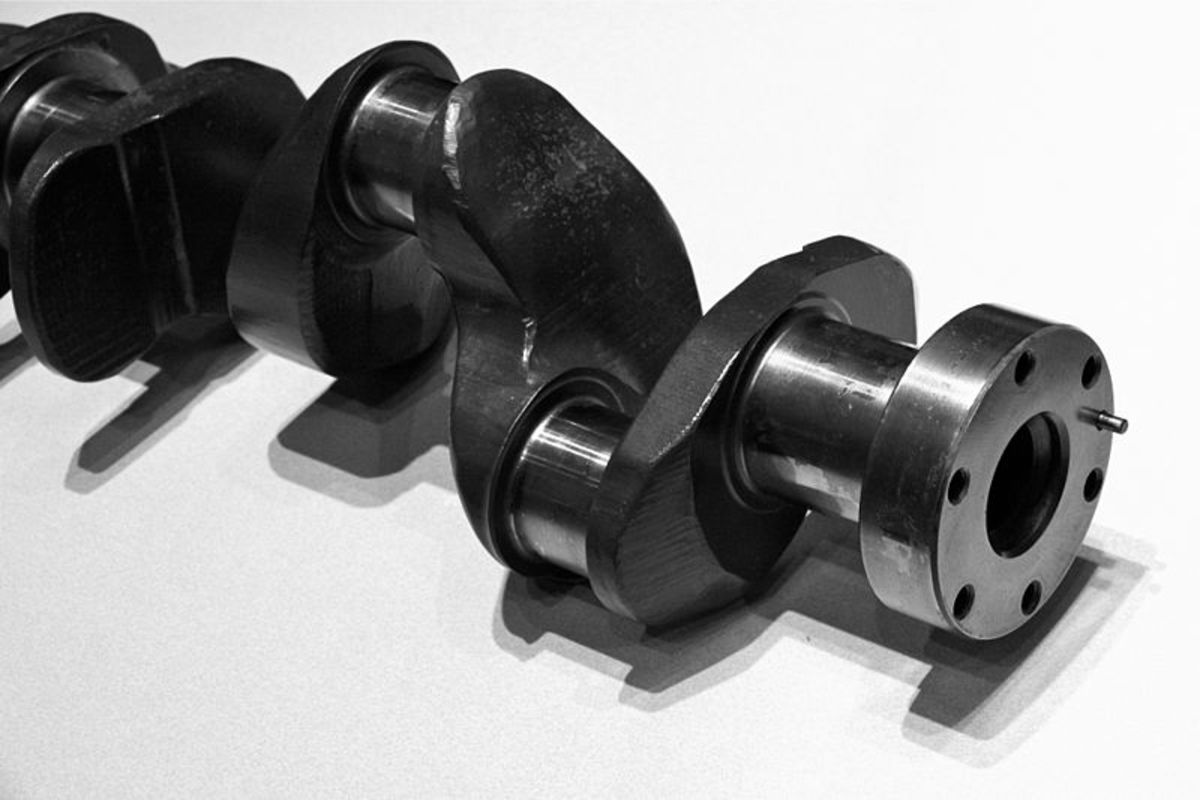

Tire Card Threads.

Inherently Flame retardant fibers are used for safety to fire.

Filter Fabric for use in Industry.

Industrial Yarns and Fabrics.

There is such a huge demand for the Industrial Yarns that manufacturers of products like motor car and other such manufacturers are trying to find alternate sources for yarns from natural fibers to man made fibers and new types of yarns.

There are others who manufacture Canvas and Tarpaulin who also need very strong type of yarns that go in to the production of such fabrics.These types of fabrics are now not made by any yarns a new technology or technical textiles has emerged that has made a revolution in the manufacture of several types of synthetic fabrics such as heavy bed spreads,seat belts,bullet proof jackets and many such fabrics which does not burn,get torn,water or stain repellent or water proof,fire proof,bacteria proof,stain proof,dust proof,mosquito proof,sweat proof,air proof and any proof you want.