What is a Life Cycle Assessment (LCA)?

Life cycle assessment (LCA) is the analysis of the complete life cycle of a given product, commodity, or process. The investigation of the product or process involves looking the resource costs associated with its manufacture, use, distribution, and destruction. Other names for this assessment include "Cradle to Grave Analysis" or "Resource Balancing." The concept of conducting a detailed examination of the life cycle of a product or a process is a relatively new one that allows for an explanation of its impacts to the environment.

An LCA will give you a very detailed report of a product's impact to the environment. Impacts are the energy use and exhaust output (greenhouse gasses, pollution, etc) that are created by the development, manufacture, distribution, and use of the product. The assessment will quantify the overall impacts at every stage of a product's life and allow the reader to identify areas where improvements can be made.

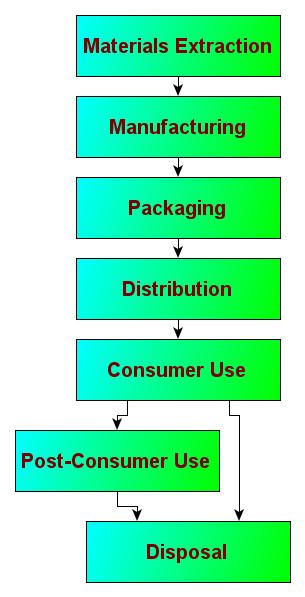

The basic stages of a product's life cycle are:

- Materials Extraction

- Manufacturing

- Packaging

- Distribution

- Consumer Use

- Post-Consumer Use

- Disposal

Materials Extraction

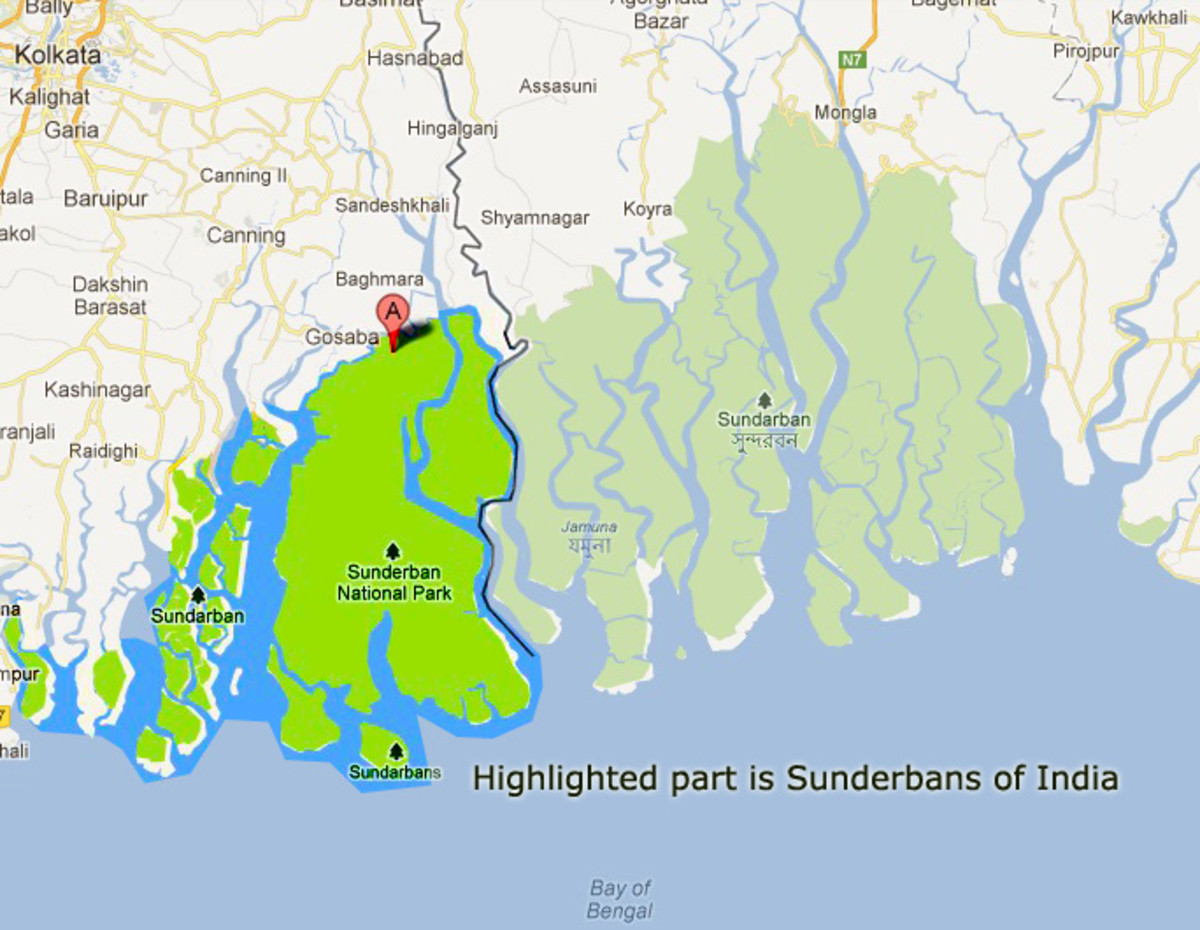

Materials extraction includes all methods by which raw materials are mined, excavated, or otherwise gathered from the natural environment. In a life cycle assessment, scientists will look at every aspect that is involved with this process. Primary items of interest include such things as energy consumption and exhaust output of the extraction equipment and materials processing facility. In some life cycle assessments, the materials processing portion of this stage may be included as part of the manufacturing stage instead.

Product manufacturers can look for ways to reduce the impacts to the environment at this stage by doing a number of things:

- Downsizing a product or its packaging

- Switching to different materials

- Switching materials suppliers

- Utilizing post-consumer materials

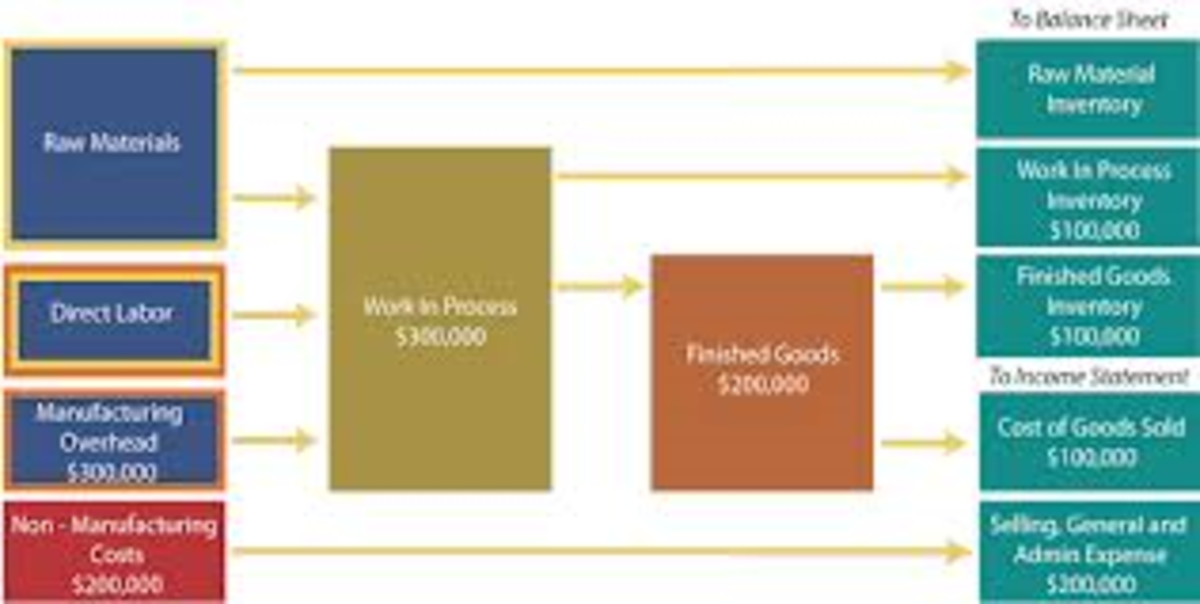

Manufacturing

Manufacturing is the process by which the raw materials are converted to a usable or sellable product. In a life cycle assessment, scientists will look at energy consumption and exhaust output of the actual product construction process. Fuel costs to supply the facility with raw materials may also be included in this stage of the LCA.

Product manufacturers can look for ways to reduce the impacts to the environment at this stage by doing a number of things:

- Utilizing energy conservation techniques

- Recycling left over raw materials

- Recycling defective products

- Upgrading to more efficient equipment

- Installing pollution prevention devices

- Streamlining the manufacturing process

Packaging

The packaging stage occurs after manufacturing but before distribution. Most products are packaged multiple times to prepare them to enter the market. Most products are first individually packaged then placed together inside of a bulk box. The bulk boxes are stacked on pallets where more packaging materials are used to secure them in place. Depending on the product, anywhere from 10-60% (by volume) of a pallet of items ready for distribution is packaging materials. In a life cycle assessment, scientist would look at the materials, energy, and exhaust created or used by the packaging itself.

Product manufacturers can look for ways to reduce the impacts to the environment at this stage by doing a number of things:

- Utilizing post-consumer packaging materials

- Utilizing more efficient packaging methods

- Selling bulk items instead of individually wrapped items

Distribution

In this stage of the life cycle assessment, scientists consider the transportation and distribution of the manufactured goods. The biggest item looked at here is the fuel consumption of the transporting vehicles as well as the greenhouse gasses that they emit.

Product manufacturers can look for ways to reduce the impacts to the environment at this stage by doing a number of things:

- Utilizing more efficient packaging techniques (more items can fit in a truck)

- Utilizing fuel efficient trucks

- Development a more efficient distribution network

Consumer Use

Consumer use is the stage where a consumer actually uses or stores the product. Items to consider in a life cycle assessment would be such things as: Energy consumption of the product (including batteries), toxic emissions due to use or storage, product efficiency, and durability.

Product manufacturers can look for ways to reduce the impacts to the environment at this stage by doing a number of things:

- Developing more energy or materials efficient products

- Developing higher quality products

Post-Consumer Use

In this stage, products are recycled or reused. Recycling means that the materials in the product get extracted and used again to create new goods. Reuse means using the item for something other than its originally intended use. Reuse also usually extends the life of the item and delays it from entering a landfill. In a life cycle assessment, scientists consider the benefits of recycling and reusing a product as well as its recyclability. This will typically lower the items overall impact on the environment. Recycling processes should also be considered in the analysis. Energy is consumed and exhaust is created during all recycling processes.

Product manufacturers can look for ways to reduce the impacts to the environment at this stage by doing a number of things:

- Using materials that are more easily recycled

- Indicating on the package that the product can be reused or recycled

- Utilizing more environmentally friendly materials

Disposal

This is the stage where the life of almost every manufactured good comes to an end. Disposal can either include burial in a landfill or incineration. In a life cycle assessment, consideration should be given for the energy and exhaust that will be produced by the incineration of the product. Items placed in a landfill can still impact the environment as well. Consideration should be given to the potential pollutants harbored by the items buried in a landfill such as landfill gases and chemical leachates. Fuel costs for landfill equipment and garbage trucks should also be included in the analysis.

Product manufacturers can look for ways to reduce the impacts to the environment at this stage by doing a number of things:

- Utilizing environmentally friendly materials

- Using less materials in a products manufacture.