Cranes – A Revolution in the World of Machines

A crane is a wonderful machine – in fact, a revolution in the world of engineering! This huge, yet simple-looking appliance is a true friend of man, because it has made the most laborious jobs of moving extremely weighty objects easy. It is one of the oldest machines helping man, though powered in its initial times by beasts or humans when it was first invented in the 6th century BC in Greece. It gradually evolved and today we can see some amazing cranes. But there are more cranes in this world than those which we see usually on construction sites and are a lot more interesting too. An interesting fact about cranes is there are many types of them. Let’s see some.

Mobile Cranes

This is the most basic type of crane and contains a telescopic boom or a steel truss mounted on a moving platform, like wheel, or a rail, or even a cat truck. The boom is pivoted at the bottom and can be elevated or lowered by hydraulic cylinders or cables.

Mobile cranes are again divided into the following types:

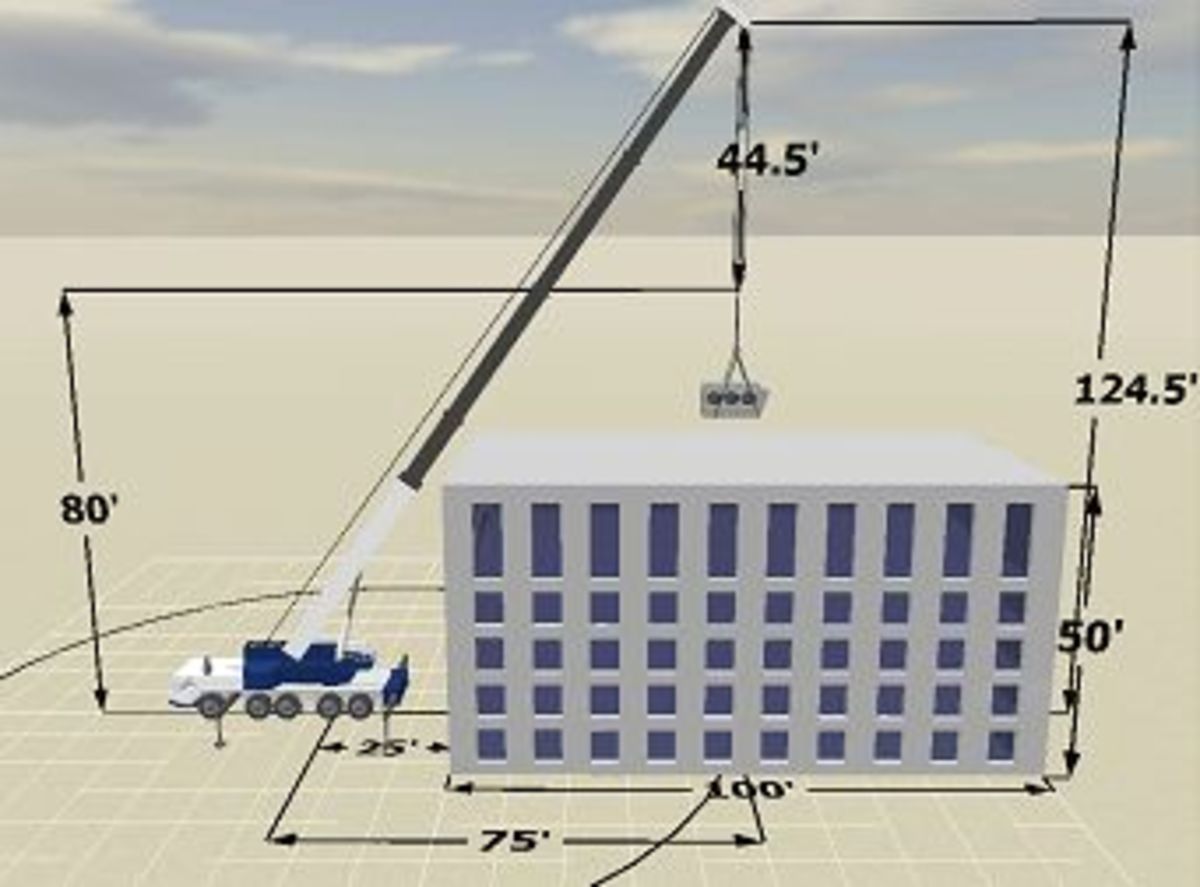

Hydraulic Truck Cranes: These are standard in mobile cranes and use hydraulics to lift thousands of pounds that in turn use force transmitted through oil thrusting the boom as pistons pushed in opposite directions. These cranes are essential for building important projects like airports, roadways, bridges, huge buildings and more.

Rough Terrain Crane: This crane is mounted on a moving platform having rubber tires, meant for working off road. The outriggers of the crane extend horizontally or vertically to level and make the crane stable while lifting objects. These cranes have a single engine, and the same engine is used to operate the undercarriage and the crane too. The engine is mounted in the undercarriage more often than in the upper portion.

All Terrain Cranes: These are multifunctional cranes meant to be run on both smooth roads and off-road at 40 mph of speeds. They were first created by Liebherr in 1981 out of a need for telescopic cranes while constructing 3,100-mile gas pipelines and pumping stations in Siberia. All terrain cranes are typically all-wheel drive and are powered by an engine or two and sport hydraulically operated winches and a telescopic boom on some models which can reach almost up to 200 feet and carry about 130 tons.

Crawler Cranes: These are a type of tracked mobile crane having either lattice or telescopic booms. Being self-propelled, they can move around a construction site and carry out jobs without the need of much setup. However they are quite expensive to transport from site to site due to their immense size and weight. These cranes can operate without using outriggers and hence provide extra stability, though some models include outriggers.

Carry Deck Cranes: These are smaller cranes moving on four wheels and can rotate their boom in full 360-degrees. They were invented in the US and are meant to work in closed spaces. They can transport the loads they lift on the small built-in deck around their cab.

Telescopic Cranes

Telescopic crane features a boom containing several tubes fitted inside one another. A hydraulic mechanism lengthens or pulls the tubes back to increase or decrease the boom’s length. They are mobile meaning that they transport objects in a flexible way. Also because they are additionally equipped with length adjustments, height is never a problem for them.

Tower Cranes

This is a modern type of balance crane. When tower cranes are fixed to the ground, they offer the best blend of height and lifting power and are even used while creating tall buildings. These are again divided into further types:

Hammerhead Crane: In this type, a horizontal long jib is connected to a vertical tower. One end of it stretches horizontally over the worksite, while the other end features a counterweight. A trolley travels along the length of this jib holding the lifting cable, and a tower crane can work at any spot within the radius of the jib.

Self-erecting Cranes: This is a marvelous type of crane because it can assemble itself fully at the worksite without needing a second crane. Because of this it saves the setup time and equipment cost. It is normally free-standing and can be made to move around the site.

Luffing Jib Cranes: These cranes are useful in urban areas which are congested and don’t allow the jib to rotate freely. The operator can elevate or lower its luffing jib to let it swing within a reduced radius. This crane doesn’t make use of a trolley which a conventional tower crane does, but rather elevates or lowers the jib as required for lifts nearer to the tower. These cranes are more expensive too due to their complexity.

Truck Mounted Cranes

Truck mounted cranes being mounted on a rubber tire truck offers great mobility. This type of crane has outriggers extending horizontally or vertically which are used to level and make the crane stable while lifting objects.

Loader Crane

A loader crane is an arm which is powered hydraulically and is fitted to a trailer. It is used to load equipment on the trailer. Its specialty is it is divided into many sections which can be folded and stored in a small space when not in use.

Overhead Crane

Overhead Crane is many times referred to as a suspended crane and is usually used in a factory. Some of them can life immensely heavy loads. The hoist is mounted on a trolley which moves in one direction along a beam or two, which move making angles to that direction along the raised or ground level tracks, generally mounted alongside an assembly area. Overhead cranes again fall under one of the following types:

Top Running: In this type, the crane bridge moves on top of rails mounted on a runway beam which is supported either by the building columns or by columns specially engineered for the crane.

Under Running: In this type, the crane bridge moves on the bottom extension of the runway beam which is often supported by the roof structure.

Single Girder: This crane comprises of a single bridge girder, two end trucks and the trolley hoist unit. The trolley moves on the bottom projection of the bridge girder.

Double Girder: This crane comprises of two bridge girders, two end trucks and trolley hoist unit, and the trolley moves on rails atop the bridge girders.

Cranes today are extremely important devices because they do the job just within minutes which would take hours and days by hundreds of people to complete. They pick up, load and unload tons of materials from ground to heights and vice versa. Therefore in the world of machines and especially in construction industry, cranes are sure to go on gaining more and more importance.