Hoisting and Lifting Machines – Mild and Obedient Giants

Development, growth and evolution in machines have occurred alongside the formation, development and growth of industries. From time to time, man has needed to find out machines for various purposes, and then improve them to make them more and more usable. One of the greatest requirements in the industrial development is hoisting and lifting heavy loads. The machines used for this job are enormous and when we see them we are spellbound seeing the ease and speed with which they move and do their job despite their enormous size. Let’s get introduced to these mild and obedient giants.

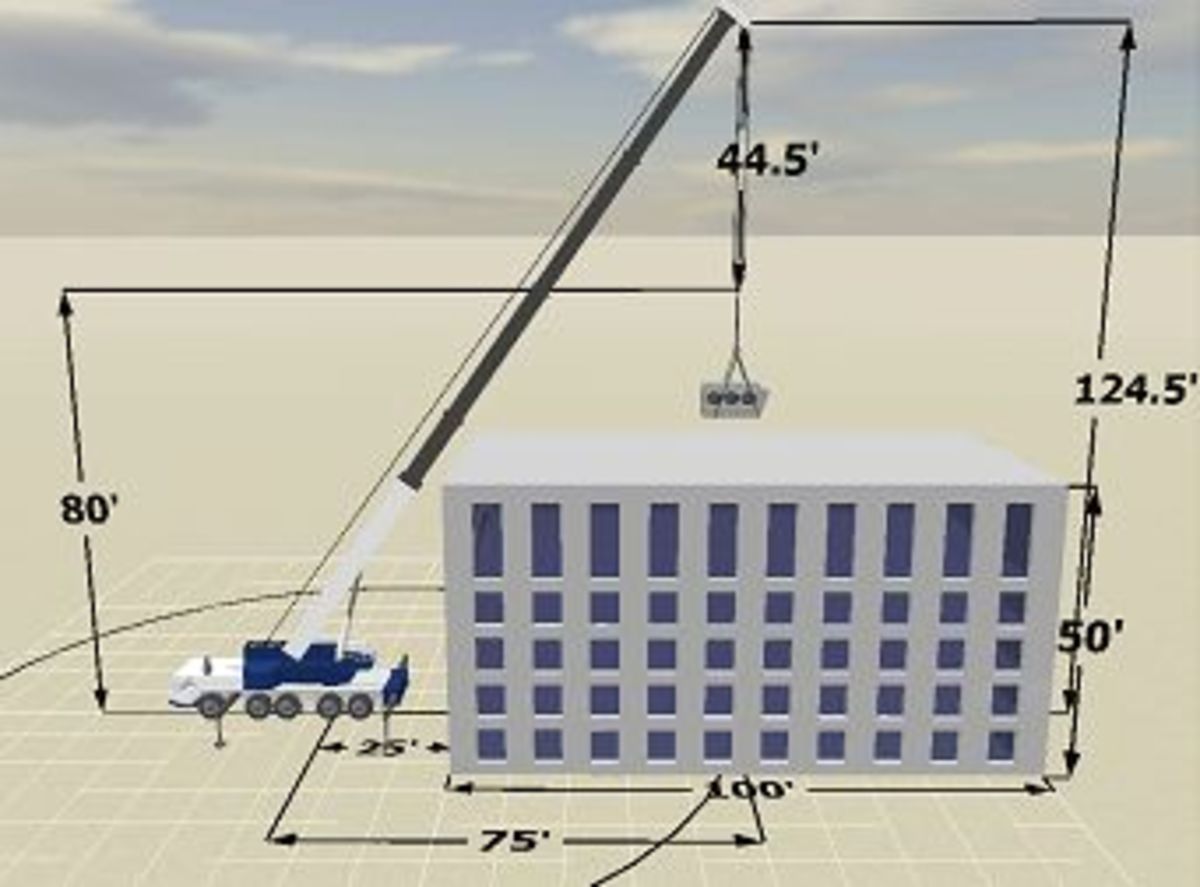

Hoisting as well as lifting require special considerations, like lift radius, capacity of machine at a certain radius, speed of wind and land conditions. Also, a proper “hook up” i.e. the linkage between the lifting device and the object to be lifted is extremely critical. It is called “rigging” and it includes techniques, principles, and information that one should have so as to make the lift safely.

For past several years, these lifting and hoisting devices have been modified according to the need. Resulting are the various types of these gigantic machines.

Boom Truck

This is a truck typically having a crane built up on it which can load and unload heavy weights on the boom truck or the nearby trucks. They have outriggers which extend vertically and horizontally and are made use of to level and make the equipment stable while performing hoisting.

Bridge Examination Unit

Bridge examination or inspection unit is used primarily for safety inspection of bridges, perform verification of load redeployment compliance and figure out ratings of bridge load. This dedicated vehicle facilitates examination of the bottom of the bridge, during which it stands on the upper side.

Container Handler

These are also known as reach stackers. They can carry a container to nearby locations extremely fast and stack them up in many rows according to the access it gets.

Bucket Truck

These are also called cherry pickers because they were originally created for using in orchards (but not only cherry orchards) and even today they are widely used there. These trucks have the same type of controls on the truck as well as in the bucket to be used by the operator.

Crane

Cranes are well-known hoisting and lifting equipment and there are available in numerous types of cranes – each having a specific usage. Their sizes too range from the tiniest jib cranes used in factories to the rocketing tower cranes used on high building construction sites.

Forklift

Lift truck or forklift is also called lift truck and is an industrial powered truck meant for picking up and transporting substances. Various companies developed forklift that we see today during the decade of 1920s. Energy used for operating it comes from propane, gasoline, diesel or battery electricity. Various attachments can be made in the forklift to increase its functionality.

Manlift

Articulating Boom: Articulating boom is used for jobs that need reaching up and through obstacles to access a job which is not easily accessed by a straight telescopic boom. This lift is almost identical to the straight boom lift in all aspects, barring its property of articulation. The boom has articulation points on it which enable it to bend in any direction thus allowing it to maneuver around several obstacles on a worksite. Outriggers can be attached to the boom lifts to stabilize a unit when the boom is stretched out in full.

Straight Boom: Straight boom lifts are normally used where high reach is to be achieved without obstruction. The turntable of the machine is able to rotate in 360 degrees with a stretchable boom that can be elevated vertically to underneath horizontal. The operator can plan and steer the vehicle when the boom is entirely extended. Models operated by propane, gas or diesel are available with two- or four-wheel drive.

Aerial Pedestal Mount Manlifts: These are largely used in special applications because they are attached to the flooring. They are chiefly used in the aircraft industry.

Mechanical Lifts: These are usually smaller models using screw threads or rack-and-pinion arrangements to raise a platform. They have a limited capacity of load they are able to lift and altitudes they can stretch to. Mainly indoor jobs are done using them, such as replacement of light bulbs.

Scissor Lifts: These are meant for working at directly overhead jobs as they can lift only on vertical planes. It comprises of a succession of connected, folding props that zigzag in an X pattern. To lift the unit, one has to apply pressure to the exterior of the lowermost set of props, which lengthens the zigzagging pattern, while vertically raising the platform. In a pneumatically or hydraulically operated machine, lowering of platform is done just by unlocking a valve to relieve the pressure.

Pipelayer (Sideboom)

These are in use since the 1920s when many companies produced sideboom additions for crawler tractors. Midwestern brought the first hydraulic-run sideboom add-on in 1953 meant for small-sized tractors. At present there are many companies selling integrated pipelayers.

Rigging

When you know capacities and weights, the rigger has to decide how to pick up the load to let it remain stable. If the rigger is trained and experienced, he can identify the danger that a hoisting process can undergo. Riggers should know factors that can influence the safety in hoisting, factors reducing capability and safe rigging practices, picking and landing weights. Riggers also should have knowledge of the proper checking and usage of slings and other hardware involved in rigging.

Telehandlers

Telehandlers or telescopic handlers look and work similar to a forklift, however it acts like a crane rather than forklift, because of having the enhanced flexibility of only one telescopic boom which can stretch upward and forward from the automobile. The operator can add many attachments at the last part of the boom, like pallet forks, lift table or a bucket. Pallet forks is the commonest attachment used most commonly for moving heavy objects to and from areas not accessible for a regular forklift.

Hoisting and lifting machines have evolved to a great extent in the course of time, and reached up to today’s most sophisticated machines offering utmost comfort and convenience in a job like lifting and moving huge loads. Seeing them, we can’t stop ourselves from admiring the engineers who create them.