Simulators for Improved Power Plant Operation and Maintenance

iiSE Simulator - Thermoelectric Power Plant

Dynamic Simulator

As the electrical demand fluctuates, emissions regulations becomes stringent and the pressure to reduce generating costs resulting from deregulation and highly competitive environment increases, power industry is facing greater challenge on maintaining unit performance, achieving operations flexibility and availability, while facing the threat of restructuring and downsizing. Hence, the emerging technology of dynamic simulation is an opportunity for the power providers to improve profitability through competent operation and maintenance.

Advantages of Using Simulator for Operation and Maintenance

As plant unit transitions from base load to cycle operation, dynamic simulator can be used to familiarize operators with automated startup applications to ensure consistent startups, minimizing wear and tear on major equipment, and reducing start-up time. It can also be used to evaluate process operations, such as optimize the highly interactive multivariable nature of combined cycle operations, and provide indexed set-points for unit coordination. Advance algorithms and control strategies can be pre-tested in simulator before it is introduced in the distributed control system. This will improve plant performance, reduced transient operation of highly maneuverable units and improved unit availability. Improper handling of machines that could introduce defect can also be avoided through training and retraining on the simulator.

Improved Maintenance

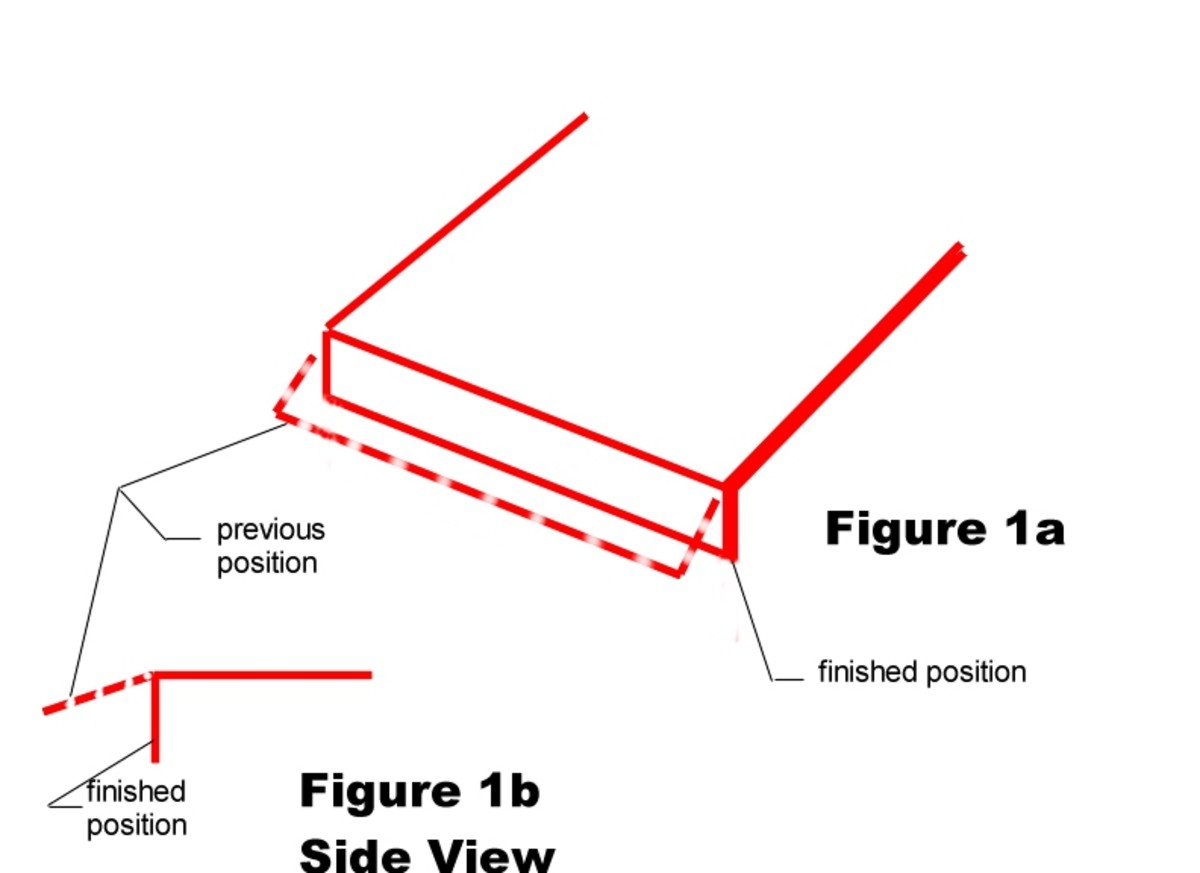

The simulator tool has led to several conceptual shifts in the way companies viewed maintenance. Without simulator, the maintenance strategy adopted was mainly inefficient reactive maintenance, defect correction or breakdown equipment repair in a trial and error approach, a technique which is counterproductive for long-term performance of the plant. Further deterioration or defect creation will be accumulated due to improper handling of the machines, apart from inefficient human resources and time consumption. With the simulator, the first conceptual shift was to change the focus of trial and error approach to a confident and efficient one, where defect prevention and defect elimination is possible and high probability to fix the problem at the first attempt with optimum results is achievable. The simulator is also diverting the attention of management to focus on the physics of breakdowns rather than the cost minimization mentality that prevailed throughout the organization. Any planned and reactive maintenance can be carried out using a pre-designed simulator with the dynamic complexity of a real equipment to foresee any possible defects that can be introduced to it. Proper and thorough procedure can be formulated out to avoid improper steps being taken while bringing the equipment down, hence reducing the collateral damages arising from performing maintenance activities.

Cost Saving

Power plant requires long-term asset management strategy due to its long operative life to find the right balance between costs, condition and reliability. Hence, maintenance and business objectives are closely related. Maintenance in practice should be linking engineering and management as the two key aspects in its business process. Cost minimization approach can be achieved through improvement in productivity generated by the adoption of improved maintenance techniques to increase generated productivity. When resources for planned maintenance are constrained, simulator enables the evaluation of various schemes for plant maintenance aimed at reducing maintenance costs and increasing plant performance. With the simulator, the organization may continue with “fire-fighting” and focus on reactive maintenance but does so more effectively and efficiently. With the intensified global competition and increasing complexity and cost of the plant equipment, the use of a dynamic simulator should be considered as a wise maintenance strategy that aims to contribute to long-term competitiveness of the company.

Related Topics

- The Difference Between Simulated vs. Synthetic (Lab)...

This article explains the difference between synthetic diamonds made in a lab and simulated diamonds which aren't diamonds at all. It also explains why some people want to buy a simulated diamond for an engagement ring. - Network Planning and Implementation - What You Need ...

A proper network planning is vitally essential for successful implementation of a network system. A smooth-running network is staged like a good running car where the users only notice they can manoeuvre the car comfortably; users do not notice the t - Free Network Troubleshooting Tools

The information we gather from users or while troubleshooting a network problem can sometimes lead us to another problem requiring more in dept level of troubleshooting. That is when good network troubleshooting tools will come in handy. Some of thes - How To Improve Network Performance | How To Analyze ...

To maintain a network, we normally ensure that the cable connections are intact, the network cards do not conflict and data communication is working. However, beyond these minimum expectations to ensure the network hardware and software are working, - Network Troubleshooting Guide - What You Should Chec...

Knowing what to look for is absolutely essential in network troubleshooting. To do so, go through the list of questions or check list below, which will help you to narrow down your problem. You will solve the problem more efficiently if you are syste

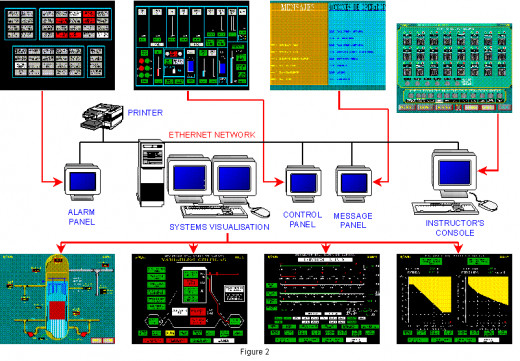

Power Plant Modeling and Simulation

Copyright

The text and all images on this page, unless otherwise indicated, are owned by Ingenira who hereby asserts her copyright on the material. Permission must be granted by the author in writing prior to copy or republish this article in print or online. However, please feel free to copy the first paragraph with a link back to this page. Thank you.

Share this page - did you know you can share this page by clicking on the "Share it" button below? This will enable you to -

Email it to friends, Link to this page, Tweet this, Blog this or, send this to your Facebook, Myspace, Digg, StumbleUpon or Reddit!

If you like what you have read, please "Vote up" by clicking the green button below. Thank you.