What is a Kaizen Event

What are Kaizen Events

Just what is a Kaizen Event? a kaizen event is an improvement team session focused on improving a specific area or facet of your business. Typically a Kaizen event will last from 3 or 4 days to 3 or 4 months, and will have a dedicated team of people working towards a common goal.

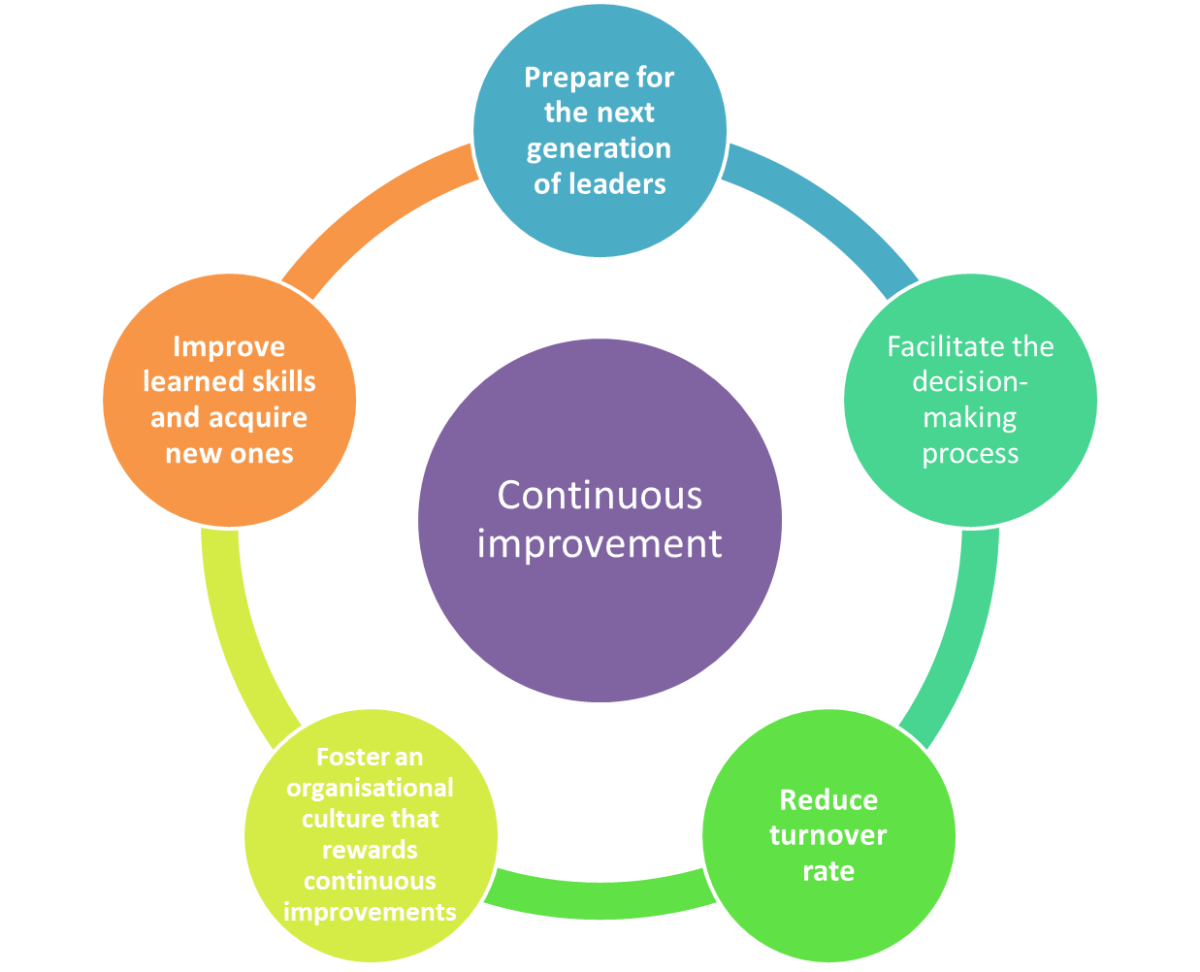

Kaizen is about continuous improvement and means "change for the better", typically kaizen is either approached as an ongoing process of many small gains or in this case as a massive step change towards a specific goal.

These kaizen events are looking to deliver a breakthrough in performance within a very short space of time and frequently achieve this (I can’t recall any real failures from the projects that I have been involved in.)

Taking Action Now Through Kaizen

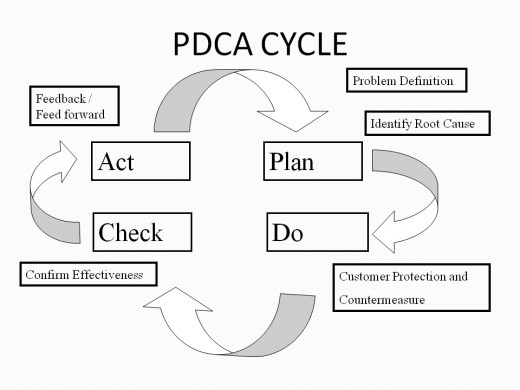

A Kaizen event is about getting things done and getting them done immediately, not about making weeks of analysis and then more weeks of choosing options, better to be 80% right today than 100% right in six months! As an outspoken CEO once told us JFDI – “Just F (insert your own version) Do IT!!!)

Lean manufacturing and kaizen events in particular are about taking action, it is not unusual to be moving whole factory floors around by the third day of a kaizen event (or sooner). You will not always be right and at times have to make adjustments at a later date, but it far better to make some improvement and then continue to improve it over time than do nothing for fear of not getting it completely right on the first attempt!

Kaizen Events Training

Benefits of Kaizen Events

Kaizen events typically are very rapid improvement methods, they can often give 20% to 100% improvements in efficiencies even in areas in which other improvements have been implemented. The focus of your event can however be based on any aspect of your business that you wish to improve; speed of order processing, lead time reduction, supplier relationships to the whole value stream.

The important thing with any event is to be clear what improvement it is that you are looking for before you start, after all, how will you know if you have been successful if you have no goal!

Kaizen Training Posters

Kaizen Events vs Ongoing Kaizen

Some "purists" will tell you that kaizen should be a continual process of little steps forward and that kaizen events are not true kaizen and that improvements made will regress quickly. However in my experience this a place for both methods if utilized correctly.

While many small steps forward are fine for continuous improvement there comes a time in every business when a chasm has to be bridged. Just taking small steps forward may not be enough to make the change necessary for our business to survive and we have to bridge that chasm in one go or fall into it!

Continual Improvement Kaizen Events

Continuous Improvement and Kaizen events

Kaizen events are typically one off events with teams formed specifically for the purpose of the improvements required. The team being disbanded and sent off to their “normal” working day after the event is finished.

The problem with this is that they do not instill a culture of continuing improvement, people wait for the next event before improvements can be made. It also leads to slippage in the improvements, as when the team is no longer there people begin to revert to old methods as things start to go wrong and as things such as customer demand change.

Without a culture of continuous improvement being already in place with established kaizen teams it is hard to maintain the full gains achieved through kaizen events. These events should be held frequently across your organization in addition to your other kaizen efforts.

Types of Kaizen Events

Below are details of different types of Kaizen events that you could run;

Kaizen Event Video

Kaizen Blitz Event

The typical kaizen event is the Kaizen blitz or Kaikaku, this is the most well known and most effective way of producing immediate and obvious gains within any environment, service or manufacturing. Led by a facilitator (often an external consultant) a team is formed and over the period of week concentrates on making improvements in a specific area.

Significant pre-planning is required to be conducted before implementation of the Kaizen Blitz or you will hit problems during the actual blitz. It is down to the team to make the analysis and suggest improvements based around the many lean manufacturing tools and principles.

Typically a Kaizen Blitz concentrates on the removal of the seven wastes and an initial kaizen blitz within an area can be very much like an initial 5S implementation with the team looking at work cell design and layout.

Value Stream Flow Kaizen

This type of event starts by mapping the value stream using Value Stream Mapping tools either across the whole of the organization or through a specific portion. The aim of this type of kaizen event is to create a future state map for the value stream which may include reorganization within the company. These events can be quite an eye opener for the company!

Supply Chain Kaizen

Much like a flow kaizen event this is very much focused on creating a value stream map of your supply chain with the cooperation and involvement of your key suppliers.

The aim being to once again create a future state map to make improvements to your supply chain for both your and your suppliers benefits.

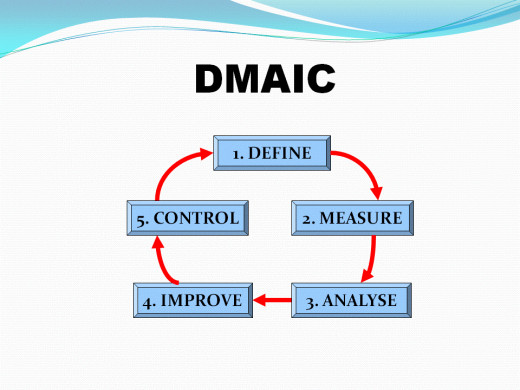

Kaizen and Six Sigma

Six Sigma is normally approached as an improvement project focusing on improving the performance of one specific area or product in much the same way as Kaizen. The difference however is that the traditional approach of six sigma is one of an improvement project led by and dictated by an expert.

This is the biggest criticism that many have of the six sigma approach, far better to have the kaizen team trained in the tools of six sigma and use them as required to identify issues within their project as they would be within "lean sigma".

Kaizen Event

Preventing Slippage after Kaizen Events

As already mentioned the biggest criticism of most kaizen events is the slippage that almost always follows. We find that once the focus moves away from the area, even onto another event, that we start to experience losses to the improvements that we made. The operators begin to encounter problems with the new setup so instead of looking for solutions to the problems they revert back to the old ways of working.

This is why many improvement events get such bad press, but it need not be like that. It is vital that the team is given the right training and support after the even to continue the process. If they are allowed to find solutions to their problems and encouraged to make additional improvements there is no reason why not only should the gains your kaizen event made be maintained, they should be built upon further.

Supporting Kaizen Events

Kaizen Events Support

There are a number of places you can go to for help with your kaizen events such as the kaizen institute or other lean manufacturing consultants. However you should be aware that you get what you pay for, the more experienced and more effective consultants are going to charge a lot more than the recently unemployed lacking in experience new consultant!

You could also approach government bodies and support groups such as the manufacturing advisory service in the UK who run many kaizen events every week, events that are subsidised by the taxpayer so will cost you much less. Other business support groups and even universities and colleges are also worth approaching; such as the institute for manufacturing at Cambridge University.

You could also look at other information available here online; lean manufacturing tools can give you an overview of the many tools available and point you at more in depth information as can the article on quality tools for continuous improvemet and problem solving.

If you have any questions or comments regarding running a kaizen event or are still unsure about what is a Kaizen event or any other questions about lean manufacturing in general please use the space below.