Manufacturing Processes - Brazing and Soldering

Brazing and Soldering

Brazing and soldering comes under the manufacturing processes category of joining. The process in both cases involves introducing a low temperature alloy into a controlled gap between metal surfaces. An important aspect of the brazing and soldering process is the preparation of the component material in the area of the joint before starting to braze or solder the joint.

The operator needs to ensure the surfaces to be joined are scrupulously cleaned, degreased and if necessary abraded. Without proper preparation the flow of liquid metal into the joint will not occur satisfactorily. Brazing and soldering relies on a capillary action taking place for the molten metal to flow between the components being joined. The parent metal remains above melting point for the duration of the process and a flux is used, specifically chosen for the metal being joined, to aid the capillary flow of the liquid metal.

High production volumes of components being joined using the brazing or soldering process are normally pre-assembled (or where necessary jigged), often with a pre-sized charge of alloy which has been calculated to be sufficient to fill the joint adequately. Heat can be applied in a number of ways but one of the most common methods is using a conveyor furnace with a torch or induction heating as the heat source.

Cycle times are dependent on heating and cooling times and the quality of the joint is dependent on the care taken preparing the surfaces. Inadequate surface preparation will cause defects due to incomplete wetting of the joints.

Equipment costs are low so consequently the process of brazing and soldering is a low cost option. Costs will increase where automated systems are employed dependent on the level of sophistication required. There is also virtually no waste of the soldering or brazing alloy, particularly where pre-sized charges are use, but the flux used for the process is consumed.

Brazing and soldering, when you consider that you are introducing a layer of material between two surfaces and rely on the chemical and physical bonding of the materials to hold the joint together, can be considered a gluing process for metals.

Abrasion of the surfaces can provide the mechanism for allowing the molten liquid to penetrate into the resulting surface crevices which when solidified effectively anchors the filler material to the surface and holds the parts together mechanically.

Advantages of Brazing and Soldering Over Fusion Welding

- Substrate remains solid throughout, therefore less heat energy is required

- Less of the substrate is affected metallurgically by the application of heat

- The process is less expensive because it requires less energy

Soldering can be differentiated from brazing because of the lower melting temperature of the filler material. Typically solder constitutes primarily of a tin/lead* alloy with alternative alloy components or percentage changes being introduced and varied to increase/decrease the melting temperature. The cut off between soldering and brazing is generally recognized as being above or below 450C.

A melting point below 450C is typically considered to be soldering and above 450C it is typically considered to be brazing, although silver soldering or hard soldering is normally above 450C and consequently should be considered to be the first level of brazing even though it is never really referred to as brazing and nearly always as soldering.

* Many modern solders have had their lead component removed and replaced for health and safety reasons under the RoHS directive (Restriction of Hazardous Substances). This has mostly affected the electronics industry that has traditionally used lead/tin solders for the production/assembly of electronic circuit boards.

Brazing and Soldering Processes

Manufacturing Processes Additional Resources

- Manufacturing Processes and Methods Process

The selection of a manufacturing process is done very much on the basis of a manufacturer choosing the process that best suits his needs. Consideration must be given to a number of factors before deciding on a... - Materials Selection versus Manufacturing Process

Material selections can determine what manufacturing processes are available, form can determine what materials can be used and manufacturing processes can determine what form can be created. So what you... - Manufacturing Processes - Joining Techniques

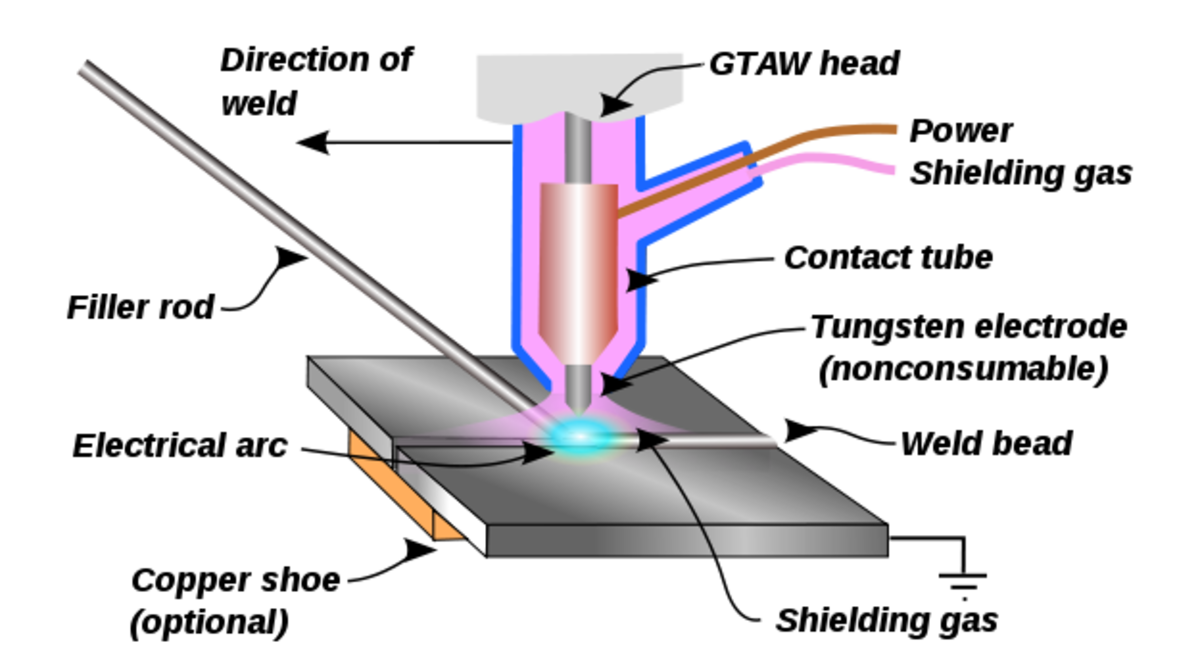

Adhesive bonding and mechanical fasteners including rivets or nuts and bolts. - Manufacturing Processes - Fusion Welding

Fusion welding belongs to the general manufacturing processes category of joining. One of the original welding techniques used was gas welding the best known of which is called Oxy- Acetylene welding. ... - Manufacturing Processes - Friction Welding

Commonly described as a welding process but it is actually a forging process which is typically used to join dissimilar metals or thermoplastics.