How do I remove a small stripped screw?

How do I remove a small stripped screw?

I need to replace -a flat battery in one of my home alarm sensors. There is a cover which is screwed in holding the battery in place. There is a tiny screw here which has been very badly stripped, that I need to remove and reuse for the new battery. What is the step by step technique for removing this tiny soft-metaled screw?

- Rob Bellposted 14 years ago

0

It looks like it would come out if you used a better fitting screwdriver. Is the one you are using big enough. Have you tried using WD40 to loosen it.

Cut a slot across the head with a hack saw and use a larger flat head screwdriver.

or

Grip it with a pair of mole grips.

or

Glue your phillips screwdriver to the screw.

or

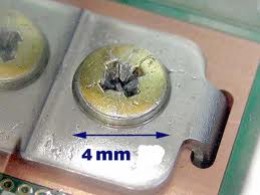

Drill it out. Thank you Rob. This not actually a picture of the screw I'm trying to remove, - just the closest photo I could find.

The screw I'm trying to remove is very small and very soft white metal. It is much more badly stripped than the one in the photo. On my screw, there is barely an edge of a tiny star shaped screwdriver slot left. My smallest ratchet-set star head fits but doesn't budge it.

I will definitely try the WD40 though, thanks for that info!

- Duddy.you can purchase a set of easy-outs though i'm not sure if they make them small enough for this screw. if the screw is really hard to get out it could have been cross-threaded when it was put in the last time so be careful about using too much force as you could shear the head off. if that happens you will have to drill out the screw and then tap another set of threads.

- Giselle Maineposted 14 years ago

0

Place a small flat piece of elastic rubber band on it (just cut out a bit from an old band you might have), place on top of stripped screw, then use screwdriver on that - it will give you more traction. This trick has worked for me in the past! - but I'm not sure if it works 100% of the time on all screws.

I use SEVERAL methods for removing stripped screws. My first suggestion is to always try to use a proper screwdriver that "fits" and doesn't slip. If screwdriver slips, then stop! get another screwdriver that might grip better. If however, the screw becomes stripped, i use these methods: Grab the screw head with a SHARP POINTY wire-cutter and grip tightly while twisting. If the screw moves JUST A LITTLE then you've got it. Another method is to grind a little NOTCH on the outer-edge of the screw... then use a FLAT screwdriver and a small hammer to "hammer" the screw at an angle untill it unscrews. Another method is using a DREMEL cutting wheel. I grind a SLOT into the screw-head then use a flat screwdriver to remove the screw. Another method is to GRIND-OFF the screw head (using a cut-off-grinder or dremmel) . Then use a pliers or wire-cutter to unscrew the stub sticking out. Some screws are located on metal that can be HEATED without damaging surrounding items.. LIKE on a car... I would heat the area with a propane torch then "ANGLE HAMMER the screw out as described above. My final method is to use an electric drill and drill out the head of the screw.

All of those methods have advantages and disadvantages. Some can not be used in certain situations ... like when there is tight work-space and you cant ANGLE-HAMMER the screw... or etc etc. What i am trying to explain is... you have to look at each situation closely and choose which "method" might work the best.If everything else fails try this: File one side of the screw to make a flat edge and try to use a small set of pliars or a small wrench - Usually a 2-3mm works fine.

Use one of the screws that you were able to remove so that you can best judge what size drill bit you need to drill through the centre of this screw.

The problem here is that you could very likely ruin the existing female threads.

. . . .so never mind, you need a small pair of vice grips to lock onto it from the outside diameter, and get it started twisting and shouting. Before long, you'll have it doing the "mash potato," and the limbo, and the. . .. yeah.Hey Thunder...

Take a run to the hardware store and pick up a set of screw extractors, and a set of titanium or other quality set of drill bits. The screw extractor will partner with a specific drill bit size. Using a drill bit that is smaller than the diameter of the actual screw body (not the screw head/top), drill straight down into the middle of the screw. Once you get deep enough to insert the extractor, purposely but gently tap the extractor in with a small hammer. Use some 'liquid wrench' or similar spray to loosen screw, then using the wrench handle for the extractor, purposely but slowly uncrew the screw. If the extractor slips, tap in again, or drill a little deeper, then try again. Remove screw, replace with new, and always use the right size screwdriver for the screw. Hope this helps. Peace. Kawi.

Related Discussions

- 2

How do I open something with a stripped screw?

by InterestCaptured 13 years ago

How do I open something with a stripped screw?

- 2

How does one remove screw hooks from say, a small table?

by Marina 13 years ago

How does one remove screw hooks from say, a small table?I built a small nightstand table and forgot to slide the back panel in. The side screws were tightened with screw hooks.

- 4

How to remove a rusted screw?

by Paul Edmondson 14 years ago

How to remove a rusted screw?I'm trying to remove a screw that is rusted and stripped. I've sprayed it with wd40 and tried pliers, but no luck getting it out. Any tips on how to get this screw out?

- 29

How Do You Break And Remove Pus From Pus-Filled Swelling On The Skin?

by ngureco 7 years ago

How Do You Break And Remove Pus From Pus-Filled Swelling On The Skin?What are the Home Remedies for Boils?

- 1

I have no markings anywhere. replsced 1 washer but the other is stripped. should

by robin houde 8 years ago

I have no markings anywhere. replsced 1 washer but the other is stripped. should I try to drill out,

- 4

What is the best way to get a large stripped screw out of a stud?

by radgirl 13 years ago

What is the best way to get a large stripped screw out of a stud?