Manufacturing Processes - Reaction Injection Moulding (RIM)

RIM Fundamentals of Reaction Injection Molding

Reaction Injection Moulding Process (RIM)

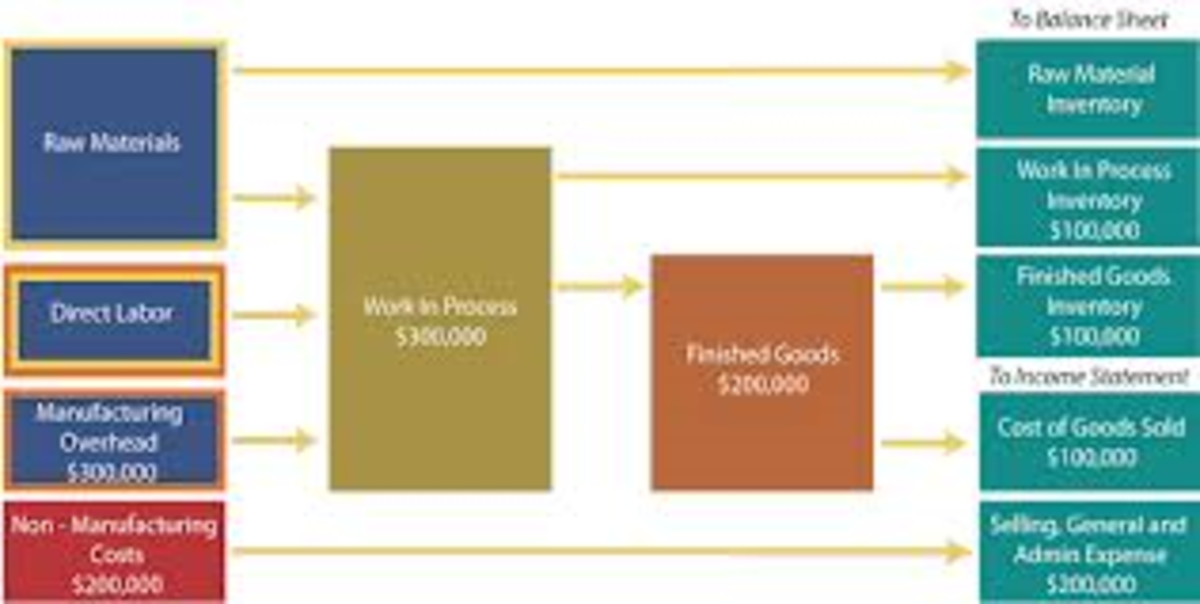

This is a permanent mould process that fits in the general category of casting as a manufacturing process and is sometimes abbreviated to the RIM Process.

The general mode of operation of this process is to combine two feeds of preheated, low molecular mass reactants in a mixing head and inject them at high speed into a split die. The mixing head opens to allow the mixed reactants into the die and closes again when it is full. The end result is a high molecular mass casting which can be removed from the mould once set using an ejector arrangement.

As with all casting processes, 3D shapes can be produced and if a low modulus material is used, slight re-entrant angles can be included in the design. This process is used mainly for the production of polyurethane, polyamide and composite components, with a wide range of chemically reactive systems being possible.

Pros

- Can produce strong flexible lightweight parts

- Relatively quick cycle times (limited by the reaction time of the polymer) as compared to vacuum cast materials

- Has a lower viscosity than thermoplastic polymers

- Lower pressure means lower clamping forces

- No waste material 100% utilization (providing there is no scrap which cannot be recycled)

Cons

- Cycle times are slower than standard injection moulding for RIM

- Raw materials are expensive

- Process is difficult to set up

- Surface textures are variable

- Can suffer flaws as a result of premature reaction

The process is generally likened to injection moulding with the obvious difference in respect to the materials used and it can be used for the production of large, lightweight and thin components. The automotive industry have adopted this process for the production of rigid foam automotive panels.

The use of composites to strengthen components through the introduction into the process of glass fibre or mica is also an attractive option for the production of automobile panels and other large sheet like components. When this is done the process is known as Reinforced Reaction Injection Moulding or RRIM.

R.I.M. Reaction Injection Moulding

Reaction Injection Moulding - Additional Resources

- Manufacturing Processes and Methods

The selection of a manufacturing process is done very much on the basis of a manufacturer choosing the process that best suits his needs. Consideration must be given to a number of factors before deciding on... - Materials Selection versus Manufacturing Processes

Material selections can determine what manufacturing processes are available, form can determine what materials can be used and manufacturing processes can determine what form can be created. So what you... - Casting Process Problems

The main problem to overcome in a casting process is porosity, of which there are 2 types: - Manufacturing Processes - Squeeze casting

Squeeze casting fits in the general category of casting as a manufacturing process. Casting has been around for approximately 6000 years, so squeeze casting is a relatively new development; being introduced... - Manufacturing Process-Centrifugal Casting & Rotation...

Centrifugal casting fits under the general category of casting as a manufacturing process and utilities a permanent mould. Typically this process is used for the production of long, hollow components that... - Manufacturing Processes - Pressure Die Casting

Pressure die casting is a process that fits under the general category of casting as a manufacturing process. It utilises a permanent mould where molten metal is forced into the die cavity through a system of... - Manufacturing Processes - Gravity Die Casting

Gravity die casting is a simple casting process which utilises reusable metallic moulds. The process is primarily used for simple shapes with some basic coring possible. It is mostly suited to casting light... - Manufacturing Processes - Sand Casting

Sand casting comes under the general category of casting as a manufacturing process and is a permanent pattern process.In other words the sand moulds are produced using a reusable pattern that is removed... - Manufacturing Processes, Full Mould Evaporative Pattern Casting

Full mould casting, otherwise known as full mould evaporative pattern casting, comes under the general category of casting as a manufacturing process and is an expendable mould and pattern process.... - Manufacturing Processes - Investment Casting

Investment casting comes under the general category of casting as a manufacturing process and uses expendable moulds and patterns.This process is sometimes referred to as the lost wax process and is one of... - Statistical Process Control versus Acceptance Sampli...

There are two types of product quality control approaches that are going to be compared and contrasted in this article, namely: Acceptance Sampling Statistical Process Control. (SPC) The purpose of...