Manufacturing Processes - Rolling And Metal Forming Process

Roll Forming Sheet Metal

Metal Rolling

Metal rolling is manufacturing process that falls under the general category of forming. It facilitates the continuous forming of bulk metal between two rotating roller tools. It is a 2 dimensional process where it is possible to create re-entrant angles in the 2D profile. It is used for the forming of any metal that is ductile at the forming temperature.

Types of Metal Rolling

- Flat Sheet Rolling, produces long continuous lengths thinning the formed material with each pass by closing the roll gap. The direction of roll can be reversed after each pass to take the material backwards and forwards through the rollers for increased process efficiency.

Foil rolling is a specialised form of flat rolling for the production of very thin sheet metal foil. Less than 200 micrometers - Shaped Rolling, a flat strip or slab of metal is passed through a series of rollers where for each stage the shape is accentuated towards the final desired finished shape.

- Transverse Rolling, uses circular wedge shape rollers to produce a relief in a bar to the required width and diameter. This is achieved in one revolution of the rollers with the relief being formed gradually as it follows the shape of the wedge.

The cycle time for this process is dependent on the length of the product but production rates are considered to be rapid.

Most rolling production is considered to be non-dedicated but shaped and transverse rolling does require dedicated rolling tools which in turn causes longer setting up times. The size and tonnage required for the rolling process also means that machines and rolls are expensive. Cold rolling requires more tonnage than hot rolling in equivalent sizes.

The quality of the finished product is generally good but surface texture will deteriorate with increasing temperature. So cold rolling produces a higher quality finish than hot rolling.

Hot rolling is defined as being when the metal is above its recrystallisation temperature.

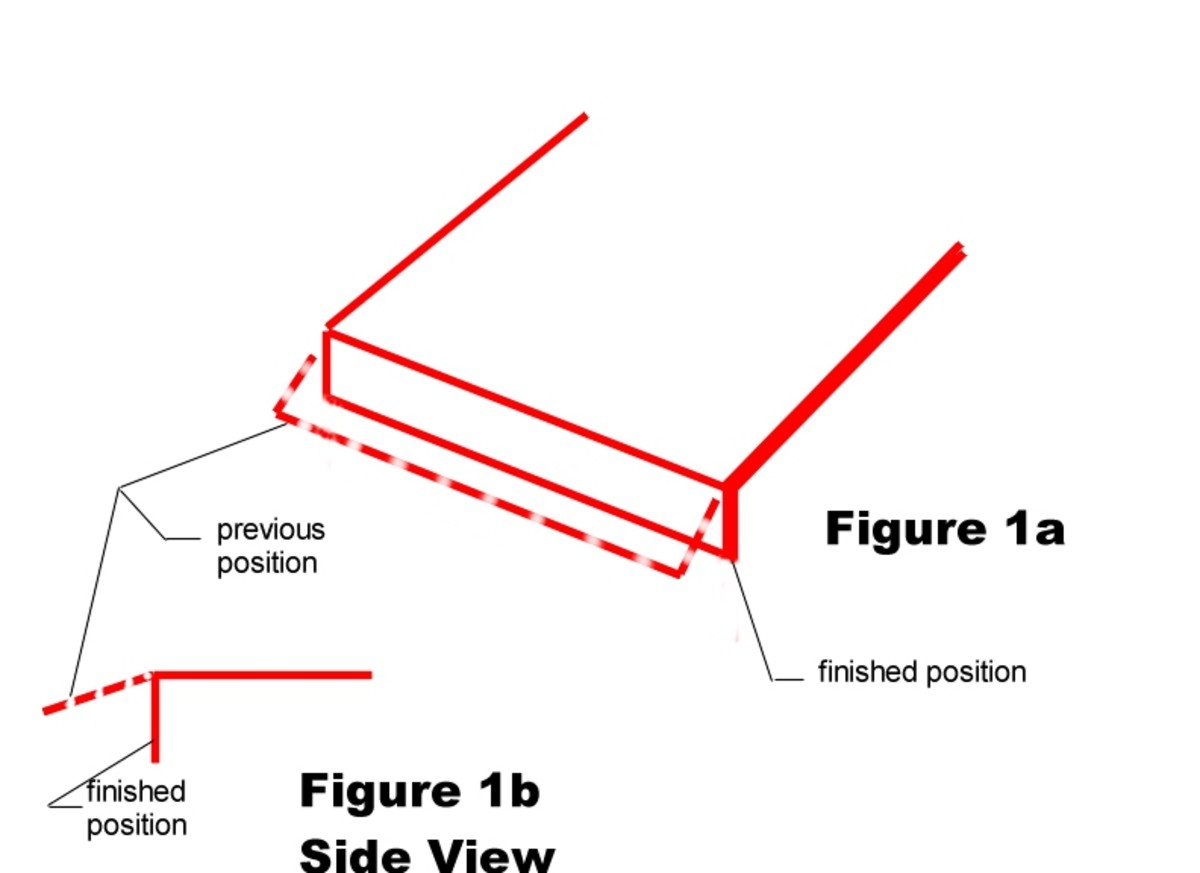

Roll Forming

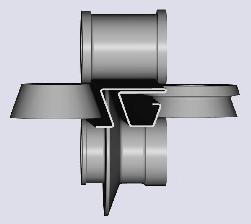

A variant of rolling is a process called roll forming, this is used extensively in the production of sheet metal components and is similar in nature to 'shaped forming' in that it produces a required shape in stages from a flat sheet metal strip.

Ref: Wikipedia 'Roll forming is a continuous bending operation in which a long strip of metal (typically coiled steel) is passed through consecutive sets of rolls, or stands, each performing only an incremental part of the bend, until the desired cross-section profile is obtained. Roll forming is ideal for producing parts with long lengths or in large quantities.'

Cold Forming of Sheet Metal Components

Aditional Resources for Manufacturing Processes

- Manufacturing Processes and Methods Process

The selection of a manufacturing process is done very much on the basis of a manufacturer choosing the process that best suits his needs. Consideration must be given to a number of factors before deciding on a... - Materials Selection versus Manufacturing Process

Material selections can determine what manufacturing processes are available, form can determine what materials can be used and manufacturing processes can determine what form can be created. So what you... - Manufacturing Processes - Isostatic Pressing

Isostatic pressing is a powder processing process that falls in the category of forming under the general category of manufacturing processes. There are 2 types of isostatic pressing processes: Hot... - Manufacturing Processes - Pressing and Sintering

Pressing and sintering is a powder processing process that falls in the general category of forming under the manufacturing processes umbrella.The powder is pressed in closed dies to form a green compact that... - Manufacturing Processes - Vacuum Forming

The vacuum forming process comes under the general manufacturing processes category of forming. The process involves producing components that are formed by heat softening plastic sheet and forcing it against... - Manufacturing Processes - Blow Moulding

The blow moulding process fits in the general manufacturing processes category of 'forming'. A heat softened hollow plastic blank, sometimes referred to as a 'parison' is clamped between two mould halves. Air... - Manufacturing Processes - Sheet Metal Forming

The sheet metal forming process comes under the category of forming as a manufacturing process. There are a number of sheet metal forming methods available which all consist of some form of deformation of the... - Manufacturing Processes - Forging

The metal forging process comes under the category of forming as a manufacturing process. It involves the forming or shaping of bulk metal between dies which mirror the shape of the component or section of a... - Manufacturing Processes - Extrusion Process

Extrusion fits under the general category of forming in manufacturing processes. The term applies to a variety of processes that involve confining a material in a container and applying a force to push the... - Manufacturing Processes - Superplastic Forming

Superplastic forming as the name suggests falls in the manufacturing processes category of forming. The process works under closely controlled conditions of temperature and strain rates which allow certain...