Manufacturing Processes - Vacuum Forming

Vacuum Forming

Vacuum Forming Process

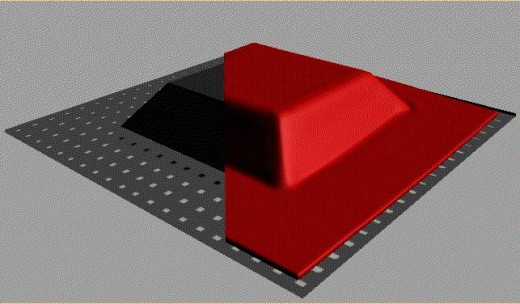

The vacuum forming process comes under the general manufacturing processes category of forming. The process involves producing components that are formed by heat softening plastic sheet and forcing it against the form of a cooled mould using a vacuum to pull the material to the mould. Once shaped it is allowed to cool.

There are many similarities between vacuum forming and superplastic forming with respect to the the tools used for the process. There are, as with the superplastic forming, three primary processes for vacuum forming:

- Vacuum Forming, where a heat softened sheet of plastic is clamped over a female die and a vacuum is pulled underneath the sheet to pull it into the dies cavity profile to take the shape of the die cavity.

- Drape Forming, a heat softened plastic sheet is placed over a male die and a vacuum is pulled through the die to draw the sheet over the profile to form the shape of the component.

- Plug Assist Vacuum Forming, this is where a heat softened plastic sheet is pushed into a die cavity using a mechanical male plug or plunger to assist. Once the first stages shaping has taken place using the plug, a vacuum is drawn through the die to pull the plastic sheet into the die cavity to create the final form.

The process is used to produce 3D shapes with what are effectively constant section thickness's with no re-entrant angles. There is significant molecular orientation that takes place in amorphous thermoplastics and good surface texture is achieved. Albeit that reproduction of fine details are limited.

The tooling is relatively inexpensive although fully automated machines are expensive. The cycle times are dependent on the heating and cooling times of the plastic sheet. Using the automated machines reduces cycle times.

Vacuum forming is suitable for processing most thermoplastic materials.

Vacuum Forming - Simplicity Itself

Manufacturing Processes - Additional Resources

- Manufacturing Processes and Methods Process

The selection of a manufacturing process is done very much on the basis of a manufacturer choosing the process that best suits his needs. Consideration must be given to a number of factors before deciding on a... - Materials Selection versus Manufacturing Process

Material selections can determine what manufacturing processes are available, form can determine what materials can be used and manufacturing processes can determine what form can be created. So what you... - Manufacturing Processes - Isostatic Pressing

Isostatic pressing is a powder processing process that falls in the category of forming under the general category of manufacturing processes. There are 2 types of isostatic pressing processes: Hot... - Manufacturing Processes - Pressing and Sintering

Pressing and sintering is a powder processing process that falls in the general category of forming under the manufacturing processes umbrella.The powder is pressed in closed dies to form a green compact that... - Manufacturing Processes - Extrusion Process

Extrusion fits under the general category of forming in manufacturing processes. The term applies to a variety of processes that involve confining a material in a container and applying a force to push the... - Manufacturing Processes - Blow Moulding

The blow moulding process fits in the general manufacturing processes category of 'forming'. A heat softened hollow plastic blank, sometimes referred to as a 'parison' is clamped between two mould halves. Air... - Manfacturing Processes - Rolling And Metal Forming

Metal rolling is manufacturing process that falls under the general category of forming. It facilitates the continuous forming of bulk metal between two rotating roller tools. It is a 2 dimensional process... - Manufacturing Processes - Superplastic Forming

Superplastic forming as the name suggests falls in the manufacturing processes category of forming. The process works under closely controlled conditions of temperature and strain rates which allow certain... - Manufacturing Processes - Forging

The metal forging process comes under the category of forming as a manufacturing process. It involves the forming or shaping of bulk metal between dies which mirror the shape of the component or section of a... - Manufacturing Processes - Sheet Metal Forming

The sheet metal forming process comes under the category of forming as a manufacturing process. There are a number of sheet metal forming methods available which all consist of some form of deformation of the...